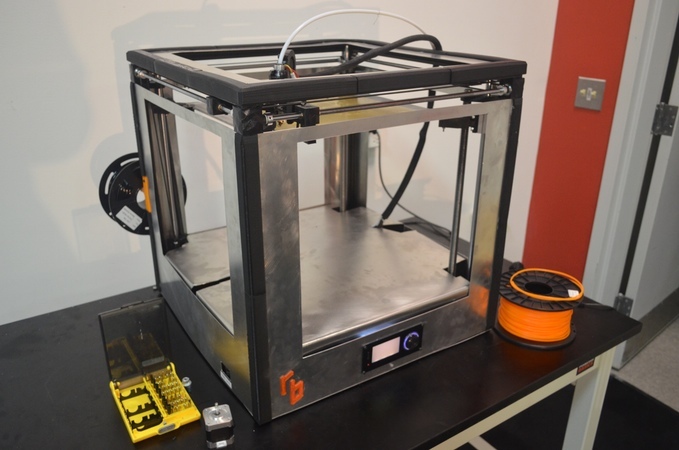

Readybox has developed what they call the “fastest consumer 3D printer”, but they’ve taken a different approach than we’ve seen elsewhere.

There are multiple claims to the title of “fastest consumer 3D printer” these days. We even wrote about one just the other day. Most of the new “fast” printers employ a computation approach to the problem: they believe the speed barrier is really the processing capacity of the printer’s controller, which must very rapidly calculate and control printer motions. To overcome this, they’ve installed a vastly faster real-time processor.

This is not Readybox’s approach. Instead, they view the issue as mechanical. They explain:

First of all, the movement systems can usually only reach maximum speeds of 200-250mm/s. This is often due to friction and heavy printer parts impeding the acceleration, or simply due to motors not being strong enough to move quickly.

If a printer can overcome these obstacles and increase movement speed, it is then limited by extrusion (the amount of plastic it can push in a certain amount of time). Most extruder motors can only apply a certain amount of force to plastic filament before the filament breaks or the motor stalls.

Using a new, patent-pending extrusion system, Readybox is able to avoid this breaking and stalling and to apply significantly more force to the plastic. This eliminates clogging and allows plastic to flow faster than previously possible. It also means that even though Readybox uses a larger 0.6mm nozzle, it can move at speeds much faster than existing printers.

We’re intrigued with the notion of using an oversize 0.5mm nozzle, which otherwise has been used by manufacturers to print bulky objects faster by having very coarse extrusions.

Aside from speed, the Readybox has some useful automation features:

- Automatic bed-leveling using a “High accuracy calibration probe”

- Automatic nozzle cleaning. We’re not certain how this works, but it sounds useful

- “Maintenance-free build plate” enables prints to stick without the need for any additional tape, glue or other adherence methods

- High-pressure extrusion system that applies “significantly” more force to push plastic through the nozzle, leading to an “elimination” of clogs

The Readybox has a massive print volume of 330 x 330 x 330mm, and is said to be “maintenance free”.

We’re curious about the processing speed as focused on by the other manufacturers, though. It turns out that the Readybox includes a faster “next generation 32bit ARM based controller board” that likely provides more oomph to handle the faster speeds.

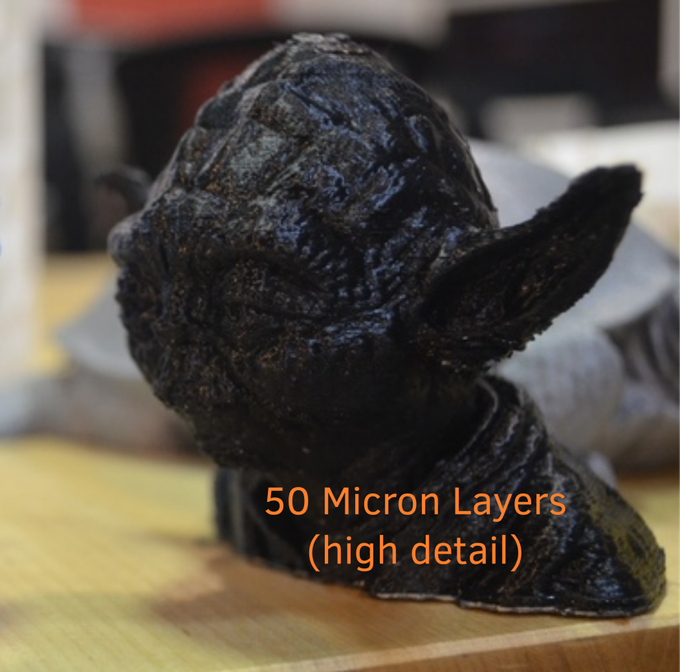

The key to the success of this unit is perhaps the print quality, as faster speeds typically result in lesser quality. Here we see an image of a sample high resolution print from the Readybox, said to be with 0.05mm layers. We’re not certain of the print speed used to produce it.

The price of this unit, as you might imagine, is higher than some consumers could afford. As of this writing, the initial batch of USD$2,499 units is long gone, but you can still catch the early bird price of USD$2,999. The production batches will be priced at USD$3,499. It’s a larger price for a very powerful 3D printer.

Via Kickstarter and Readybox