Once the 3D printing is done, the post processing begins. That’s the “dirty” secret of the industry, but it’s one that vendors like Anmasi can solve.

There are multiple 3D printing processes in existence today, and each offers different advantages and disadvantages. It’s up to the users to determine which process – and ultimately which equipment – best meets their application’s needs. However, some of those 3D printing processes require extra care after printing.

A popular feature in many 3D printing processes is the inclusion of support structures. Where gravity is to disturb the formation of the object during printing, support structures keep things in order by holding up overhangs.

But they’re not part of the final object and must be removed after printing.

It’s often possible to simply pick off support structures by hand, but that requires significant and tedious manual effort. That’s code for “expensive”.

Another problem with support structures is that they are sometimes embedded within an object where they are not easily removed by hand. I”ve personally encountered this situation and it’s not pleasant: large chunks of support have to be pulled out through a tiny hole.

That is, if you even have a hole to remove them!

Because of the above, many systems have moved to a dissolvable support system, where you simply dunk your print in a bath of solvent and let chemistry do the work. Depending on the amount of support material and the dissolving system involved, the cleaning can be quick or slow. Regardless, it doesn’t require much human labor to execute.

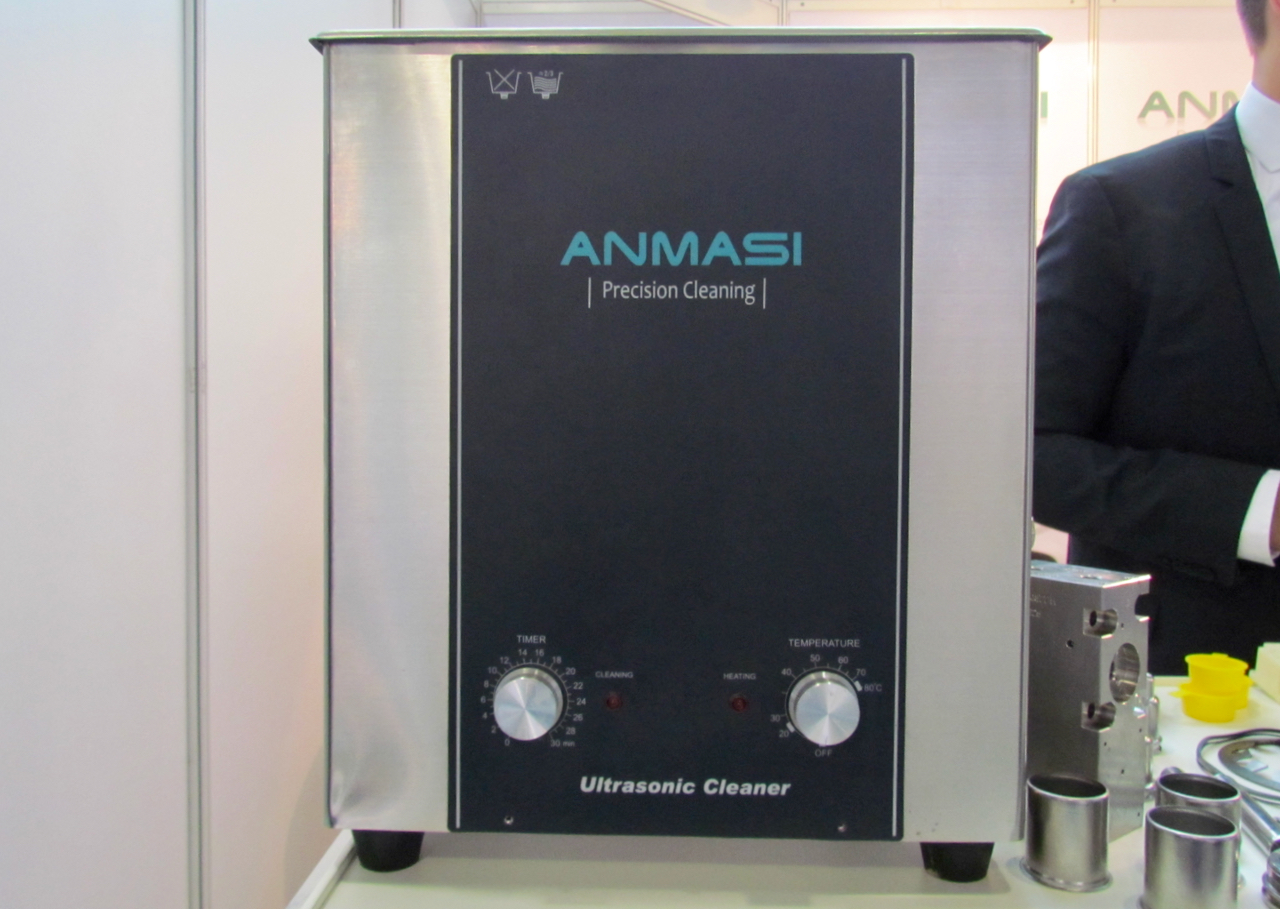

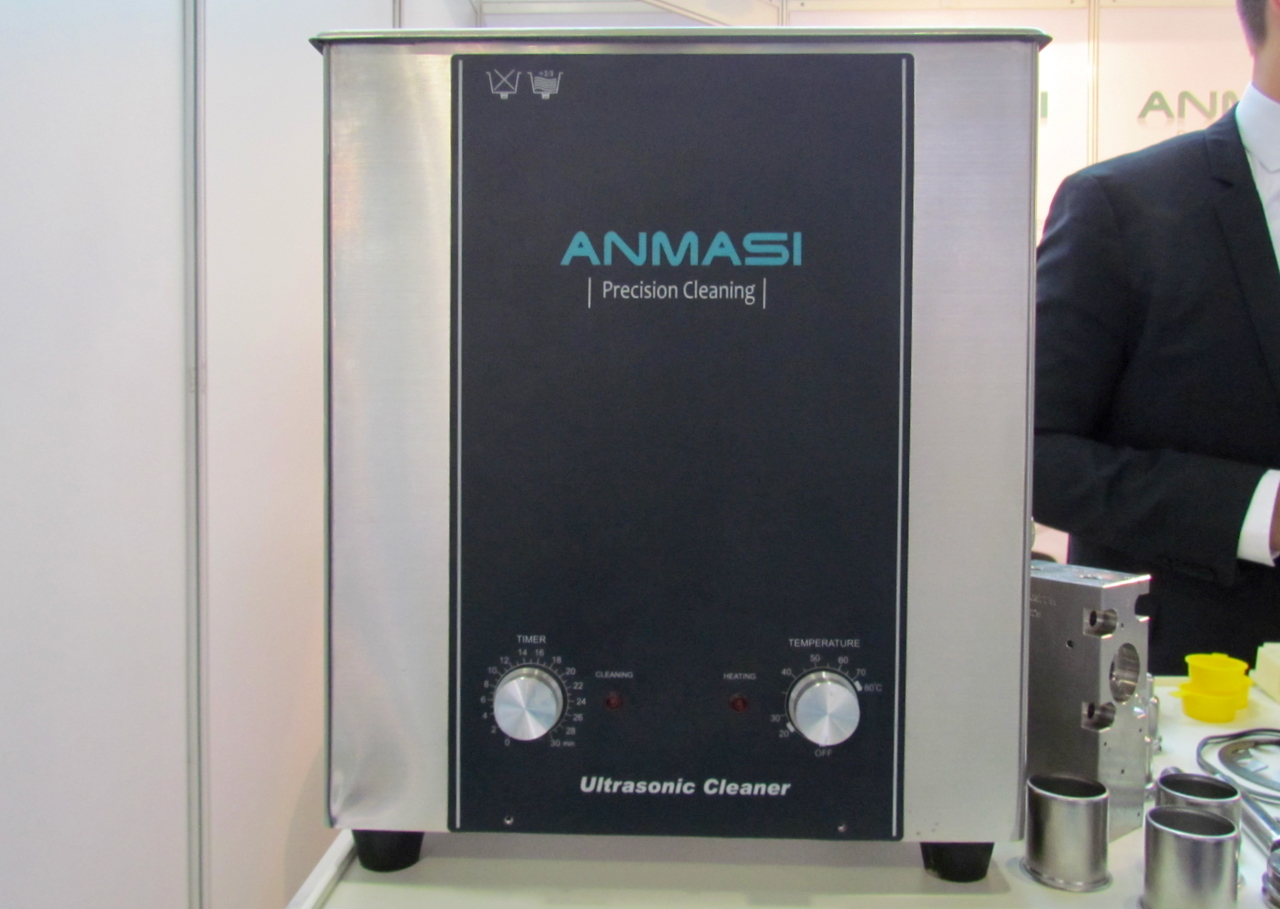

That’s where companies like Anmasi come in. The 70-person, Denmark-based company produces robotic, transportation and cleaning systems for industry. Their goal is to automate as much of the work in a factory as possible.

Their capabilities include ultrasonic cleaning methods as well as a variety of solvents. These components are assembled into a fully automated system for factory clients on a custom basis.

And it’s not only the cleaning that is handled. Anmasi examines what to do before and after the cleaning process and develops custom robotic solutions to handle, for example, baskets to move parts through a complete process.

As you might imagine, this style of solution is only viable for larger companies using 3D printing on a production basis, where repeated printing of similar parts occurs. Typical installation costs for an Anmasi system may run in the USD$33-55,000 range.

In order for factories to truly integrate 3D printing technology into their processes, systems like Anmasi will be required, as it likely doesn’t make sense to introduce manually operated 3D printers into an already-automated production process.

Via Anmasi