I’m reviewing the product list from an Australian company, 3D Formulations, which provides a number of non-printing supplies for 3D printing operations.

This seemed like an unusual focus for a 3D printing startup, so I wanted to find out more about what they were attempting to do. You see, there are countless companies providing supplies for 3D printing operations, but invariably they primarily provide materials that are printed – the model materials and the support materials.

That does not seem to be what 3D Formulations is producing. According to their press release:

For the past two years, the teams attention has been laser-focused on additive manufacturing technologies, and the burden of post-processing, in particular, dangerous and unpredictable “subtractive” practices such as vapour-smoothing and sanding, which are contradictory to the very principle of “additive manufacturing”.

This is indeed an area worthy of support, as it often seems that post processing 3D prints has been ignored by all the recent 3D printing innovation. To put it another way, how important is it to 3D print an object 50% faster if it still takes you 5x as long to do the post processing?

That post processing work typically entails two goals:

Cleaning the print of excess material, particularly support structures or stray resin

Smoothing the completed print so that its surface does not exhibit “layer lines”

3D Formulations is taking on both of these problems, specifically for Stratasys equipment, but I suspect at least some of their products can be used on prints made with other equipment.

Their PolyClean and PolyClear products are liquid mixtures that do both. PolyClean removes excess (potentially toxic) resin from Stratasys PolyJet prints, which includes their new line of color equipment, such as the J750.

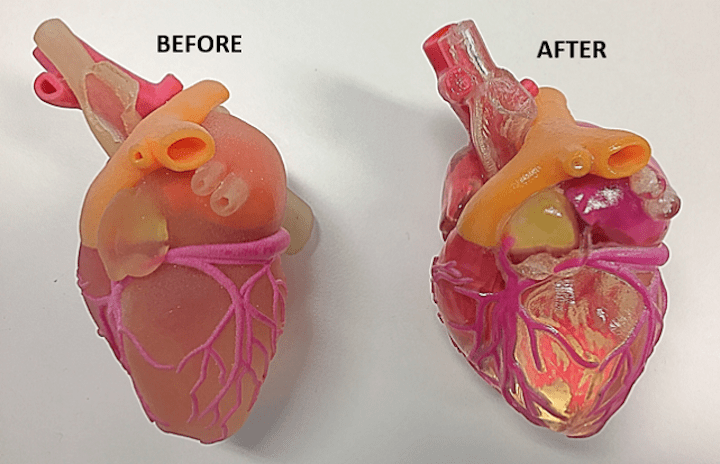

PolyClear is a product that can smooth out PolyJet prints by application. This is quite important, because the PolyJet 3D printing process does have a significant drawback: the underside of the print will always be a rough, matte-style finish because it is where the support material attaches. It’s possible to have a shiny topside on a PolyJet 3D print with the right options selected, but how can you get a fully shiny object? With PolyClear, of course. See the example at top for what this can do to a print.

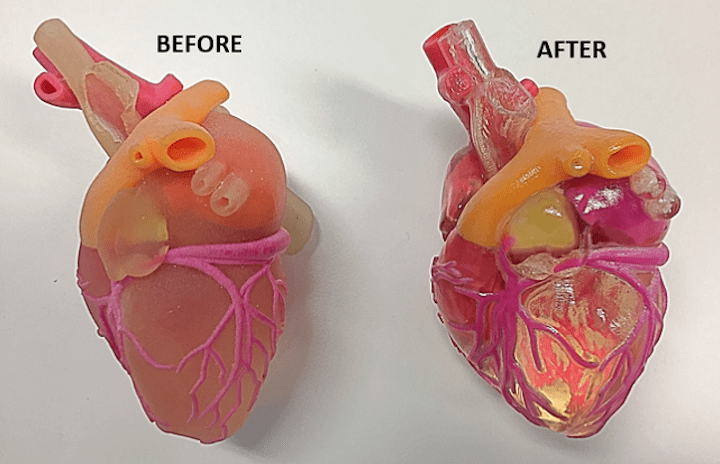

In addition to the PolyJet products, 3D Formulations also markets a substance, Proto-Fill, suitable for smoothing FDM (extrusion-based) 3D prints. Here you can see it being applied to an object with very conspicuous layering.

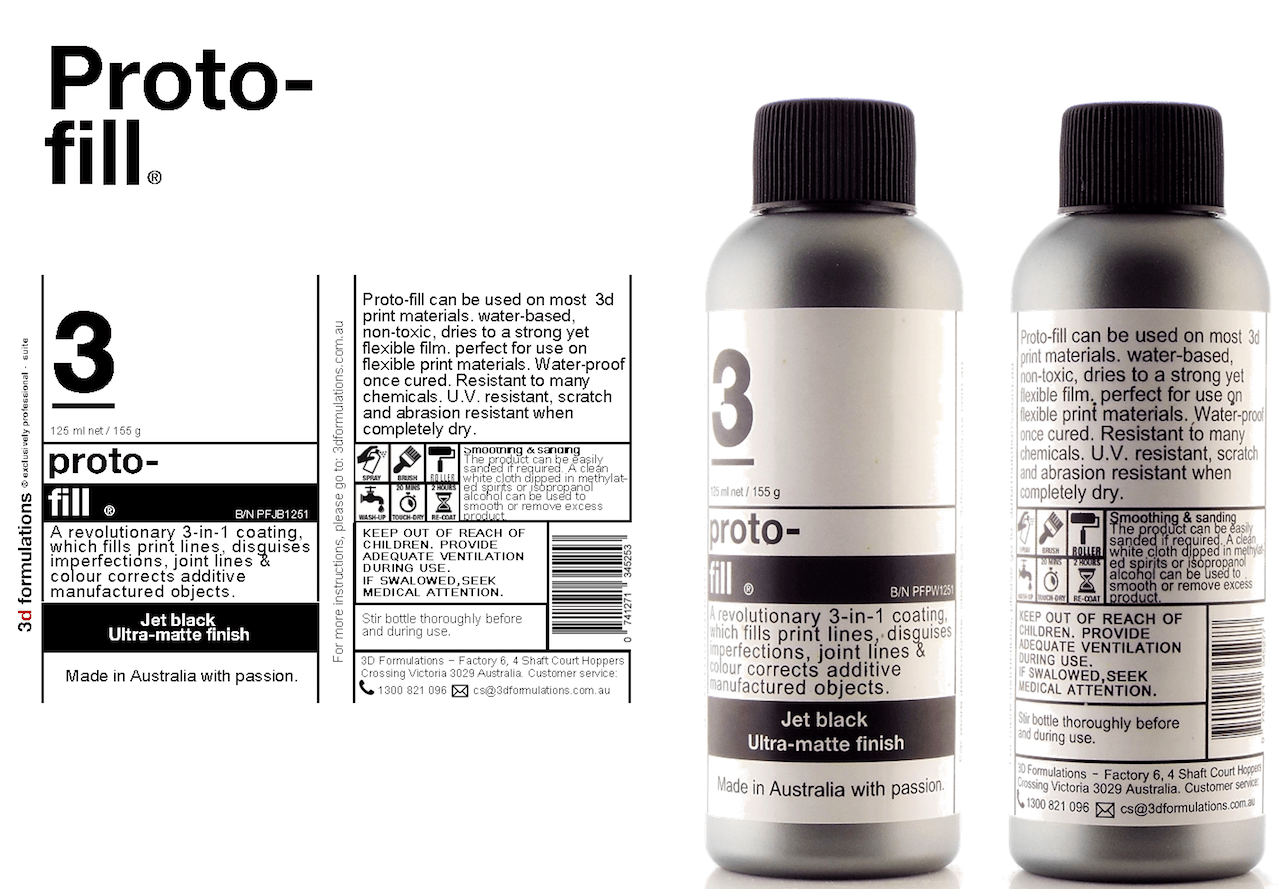

I suspect Proto-Fill may be successfully used on prints from other extrusion-based machines. The labeling says:

Proto-Fill can be used on most 3D print materials. Water-based, non-toxic, dries to a strong yet flexible film. Perfect for use on flexible print materials. Water-proof once cured. Resistant to many chemicals. UV resistant, scratch and abrasion resistant when completely dry.

It comes in jet-black, “ultra matte” finish. The company also lists Proto-colour, which appears to be a similar product but with specific colors.

Those properties listed above are quite intriguing. If true, then it may provide a way to transform otherwise less than useful prints into useful ones, just as if you had printed them in UV / chemical / scratch / waterproof materials.

I believe this is a very interesting angle on the 3D printing business that hasn’t been properly addressed. At least until now.

Via 3D Formulations