You probably haven’t heard of Axsun, but you might be hearing a lot more in the future.

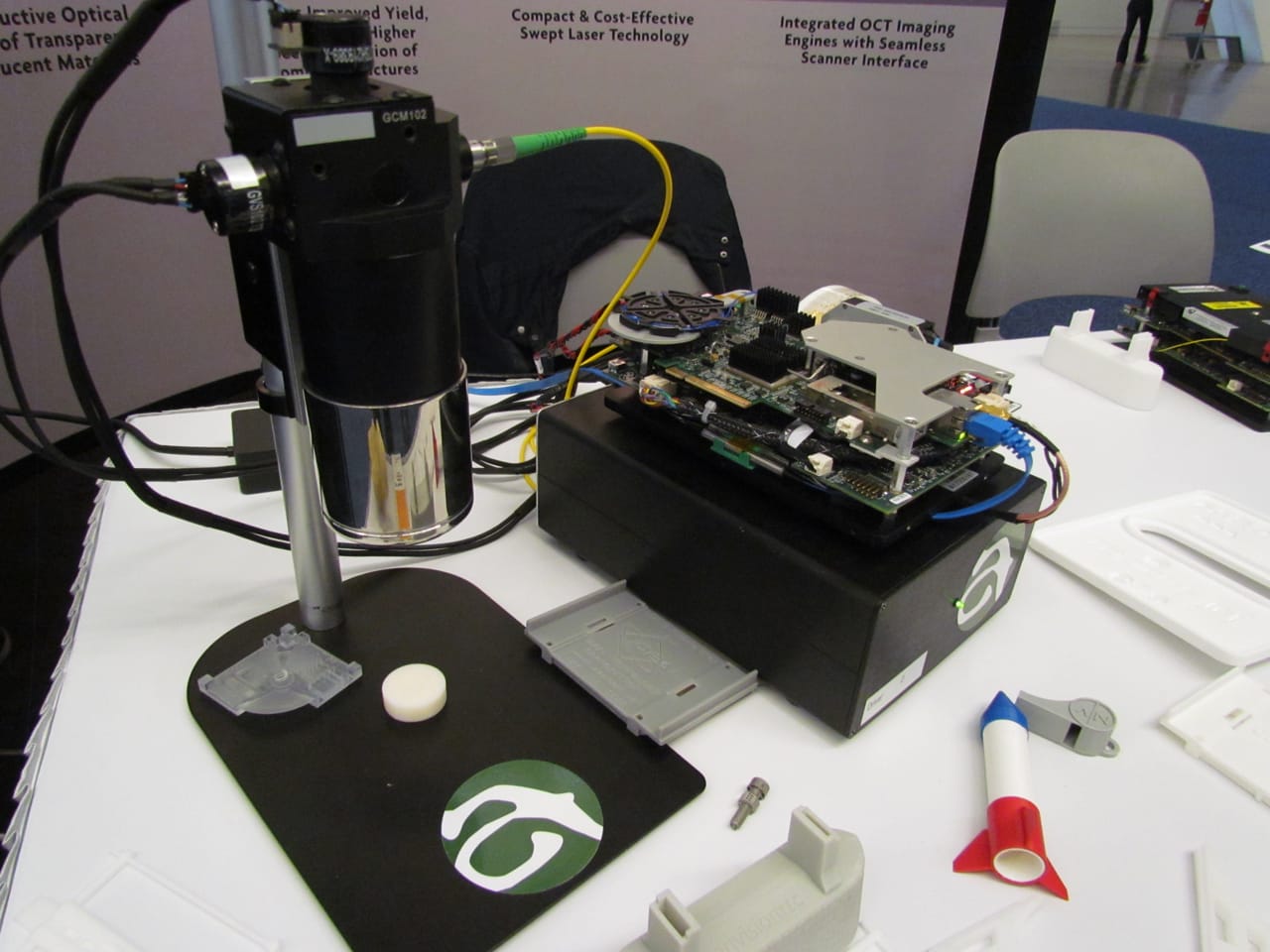

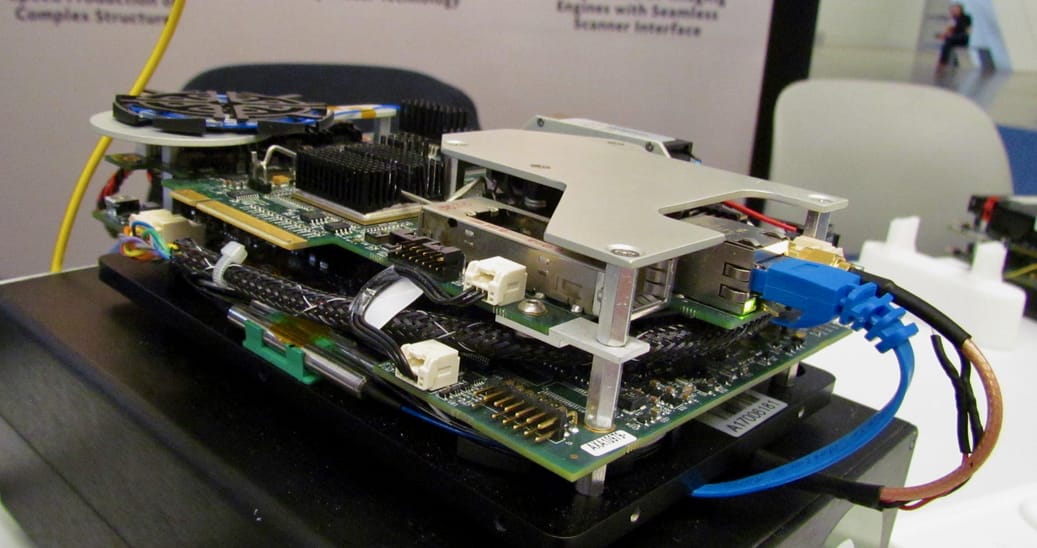

Axsun is a 100-person Boston-based company that specializes in “advanced photonics”, a science involving light and microscopic devices. Their technology uses “Optical Coherence Tomography (OCT)” in a way that could benefit 3D print operations.

This technology is well-established in the medical community, where it is used to capture highly detailed images of sub-surface structures in transparent or translucent materials. Normally, this is used to “see” into patients for medical diagnoses. Specialized lasers provide the imaging through materials.

However, the theory is that it could also be used in 3D printing.

Axsun’s proposition is that this technology could be added to a 3D printer so that the quality of the 3D print could be monitored during 3D printing.

Imagine if a layer were printed, and then a second pass occurred where the layer was inspected to the micron. It would then be possible to abort the print, or take corrective action of some kind. It may also be possible to “see” through multiple layers depending on the translucency of the particular material being printed. They explain:

This system would allow a manufacturer to identify any defects of a layer in real-time, and is unique in its ability to simultaneously image optically clear, translucent, and specular materials that can be difficult or impossible for traditional camera systems and machine vision algorithms.

You could, for example, record a 3D internal view of a printed object for post-print analysis.

In fact, they propose a number of possible applications in 3D printing for this technology:

- Real-time quality control and assurance

- On-the-fly 3D model reconstruction and

- net shape verification

- Immediate defect identification/recovery

- Non-destructive optical sectioning of transparent/translucent materials

- Real-time subsurface imaging of polymeric interfaces or composites

- Statistical process control and certification of critical parts

- Alignment of subsurface particles/fibers

- Monitoring/measurement of dynamic

- curing processes

- Characterization of laser and metal powder interactions

Basically, this is like an “MRI for 3D prints”.

Can you buy this now? Not exactly.

Axsun is proposing that 3D printer vendors incorporate this technology into their equipment. I believe this could be a very interesting feature on high-end equipment, if a vendor were to pursue it. For now, however, you can purchase the development kit for USD$50-60K.

Via Axsun