One of the most intriguing items we encountered at Rapid+TCT was what appeared to be a 3D metal printer – that could print in more than one material.

Virtually all 3D metal printers produce objects made in a uniform material, typically a consistent metal powder. Perhaps the powder has been previously mixed to form an alloy, but once it’s laid on a bed, it isn’t changing. Thus 3D metal prints are almost always seen made from a single metal or consistent alloy.

The new system is from two year old Additec Additive Industries, based in Las Vegas. Their concept is a direct deposition system, powered by lasers. The idea is to immediately melt metal material presented at the toolhead, which moves around in multiple axes to deposit material in the desired pattern.

And when I say “lasers”, I mean lasers plural. Their system employs multiple lasers. While most direct deposition systems use a single laser pointed at the meltpool, Additec uses FOUR! This multiplies the energy applied to the input metal material greatly. In fact, they told us their system could use up to EIGHT lasers simultaneously, discharging a massive 24kW upon unsuspecting metal powder. They say they have a deposition rate of around 45kg per hour, which is significant.

There is a big implication here: with more energy applied, the material can be melted far faster. This means prints can be completed much more rapidly, and Additec seems to have leveraged this capability very shrewdly.

They’ve used the increased print speed to create devices that have very large print volumes. Their standard system, which uses a delta-style approach, apparently has a cylindrical print volume of around 1500mm wide by 3400mm tall – that’s enormous!

But their larger model is apparently 2100mm x 6100mm, perhaps the largest metal print volume we’ve yet encountered.

There’s another very unique feature in this system, which you may have been wondering about. Like most deposition systems, the Additec machines use a wire delivery approach. In other words, a pre-made metal wire of appropriate alloy is pushed through to the toolhead, where it encounters massive laser energy. That’s fine, but then Additec explained that the system ALSO uses metal powder.

Their system can 3D print with metal wire OR metal powder.

And it can do so at the same time!

The implication here is that you could theoretically switch from one to the other – perhaps even a mix of the two during the print. This is effectively a multimaterial 3D metal printer.

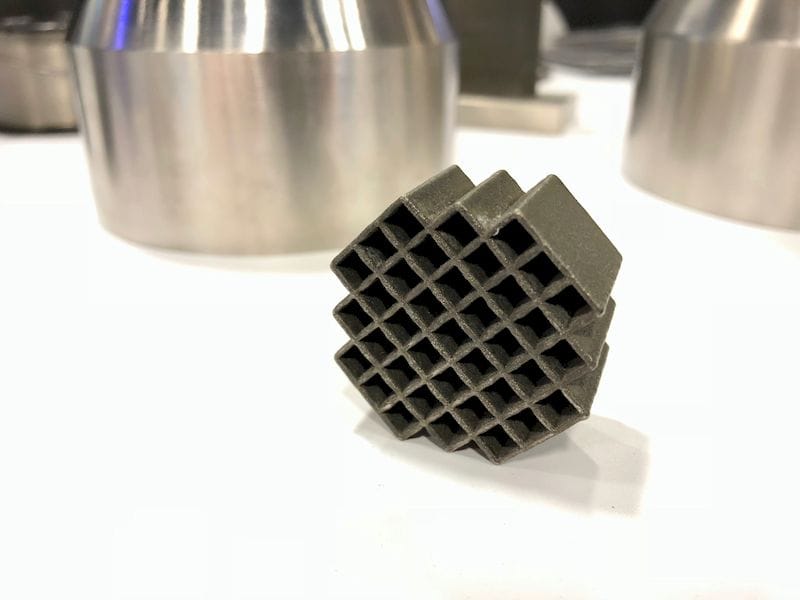

Additec explained their target market is industries where large, complex metal structures are required. An example cited was a nuclear waste grid cylinder, a matrix-like storage system for used nuclear pellets. To produce this object in conventional ways would take weeks and cost around USD$1M. But with Additec’s solution, the same object can be created in three days and cost only USD$25K.

We were unable to see the system itself, simply because it was too large to bring to the show. However, we’re told they’ve sold ten systems over the past six months, so the system appears to be proven.

One more interesting tidbit: Additec is apparently entirely self-funded. They have no major investors, and are currently undergoing negotiations so this may change. As an investment, this looks quite interesting.

Via Additec