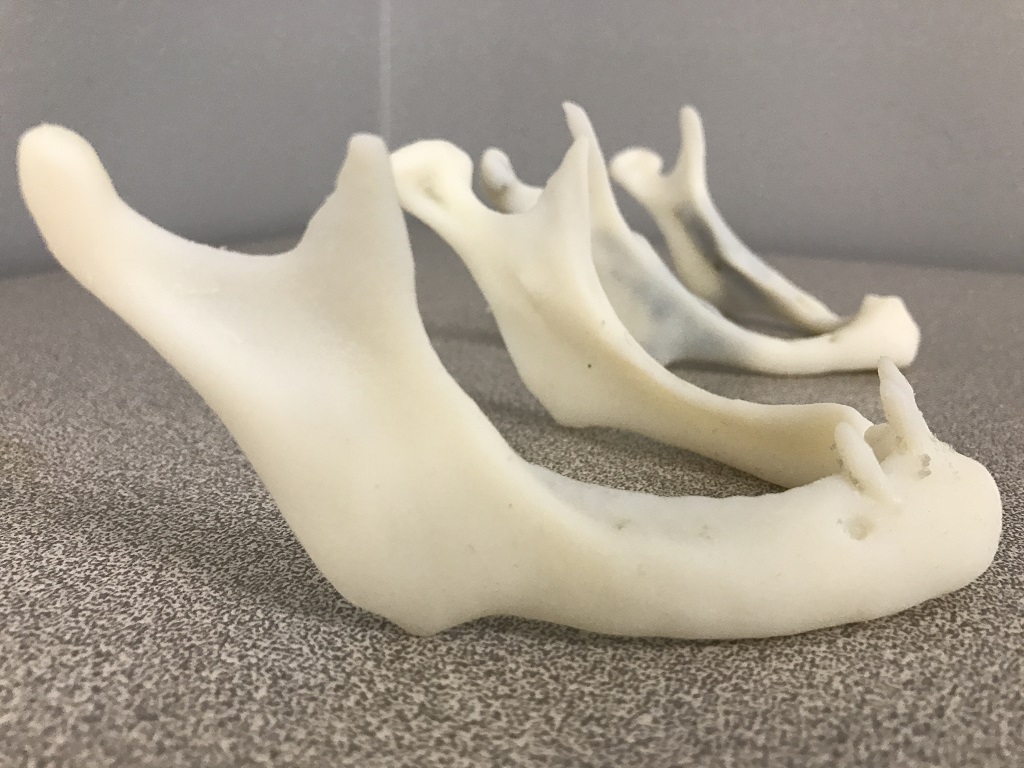

![3D printed mandibular model [Image via Stratasys]](https://fabbaloo.com/wp-content/uploads/2020/05/va_mandible_img_5eb09fcf0d21c.jpg)

Closing out 2018 on a heartening note, I caught up with Stratasys and the VA on their cooperation to bring 3D printing and innovation into healthcare.

Michael Gaisford, Stratasys’ Director of Marketing for Healthcare Solutions, and Dr. Beth Ripley, the Chair of the VHA 3D Printing Advisory Committee at Veterans Administration (VA), share a look into mandibular reconstruction.

In part one, we focus on Stratasys’ tech-driven role in bringing 3D printing to bear in mandibular surgery; here, Dr. Ripley shares the VA perspective.

Through Stratasys’ Corporate Social Responsibility (CSR) program, the company has been working with the VA for some time now in providing 3D printers and materials to support their national health network. One use case seeing growth within the broad VA health network is in jaw reconstruction — mandibular surgery.

“It’s a really tough surgery,” Dr. Ripley noted immediately.

The VA has a significant patient population of veterans who develop tumors of the mandible or have experienced trauma in the area, she explained.

“You’ve got to cut out all of the bone surrounding the tumor. Some of these can be quite large. Removing a significant portion of the jaw, there are serious deficits if you don’t replace that jaw: you wouldn’t be able to chew, it would affect how you talk, it would affect your facial features,” she said.

To rebuild the jaw, the surgical team goes to the patient’s leg and cut into the fibula to take a piece of that bone. In a complex, 12-to-14-hour surgery, two surgical teams — one working on the jaw, one working on the leg bone — take that fibula piece and shape it to fit the jaw being reworked. With such complexity in this demanding and not-uncommon procedure, the VA has been working to streamline and speed up the surgery to a more efficient process.

“We learned that with 3D printing we can create the shape ahead of time. After they shape the bone, they have to attach it to the existing jaw and they use a metal plate. These come in just a few sizes and have to be fit perfectly so it will fit flush with the jaw. We’ve started to 3D print the mandible beforehand and give that to the surgeon. They fit the metal plate around that prior to the surgery, and this allows them to save approximately two hours in the operating room, which is huge,” Dr. Ripley said.

She calls it “huge” not out of hyperbole or excitement but because of tangible benefits. The longer a patient is under anesthesia, the more it affects them. Shortening that time speeds up recovery. Time and money savings are also huge; OR time stands at about $80/minute, and with reductions of 80-100 minutes, medical billing gets a break too.

“Huge” it may be, but the VA wants to take it further: “This is really step one for us,” Dr. Ripley continued.

“Step two is figuring out if we can actually 3D print a plate that we can place in the patient, or make a cutting guide to make the surgery go faster,” she said. “That’s what it’s really about, and what makes 3D printing so exciting. As you roll this out throughout the hospitals, all of these new ideas pop up where you can improve care further.”

The plates that hold the jaw implant in place currently come in three sizes built on averages that don’t actually directly translate to actual people’s sizes. They can fit people okay, but as Dr. Ripley noted, “When you talk about fitting something into your body, you don’t want it to be just okay. You want it to be perfect.”

And that, she said, is what’s great about 3D printing: “You can make bespoke parts that fit an individual person.”

“The technology allows that point-of-care manufacturing, made for that patient at the bedside instead of far away in a factory somewhere,” she added.

![VA Puget Sound Health Care System Maxillofacial Surgeons James Closmann (left) and Jeffrey Houlton are taking the search for a perfect fit for their patients to the next level by harnessing the power of 3D printing to deliver adapted mandibular implants [Image via Stratasys]](https://fabbaloo.com/wp-content/uploads/2020/05/va_mandible1_img_5eb09fcf81993.jpg)

Point-of-care 3D printing is enabling more hospitals to create custom-fit medical models and devices. With their recent partnership with Materialise, Stratasys can offer FDA-cleared medical models, highlighting both the demand and the need for better fits in healthcare. Such regulatory clearance is appealing to the VA with its vast network of healthcare.

“We are the largest integrated health system in the country, and that puts us in a great position to take care of our veterans — and also how we advance healthcare. This size helps push forward innovation,” Dr. Ripley said, noting that “how much the VA has embraced 3D printing is something I’m really proud of.”

The VA health system has 3D printing operations in place in 20 hospitals around the US. Together, these medical teams across this network are examining best practices and working to push better innovations into better healthcare.

“By putting 3D printing in the hospitals, it allows the front line staff to really innovate. Who really knows what the patient needs best? The person taking care of them every day, the person interacting with the patient every day, not someone far away,” she said.

While regulation and the overall ‘cool’ factor of the technology are often at the forefront of conversation, these aren’t the focus for the VA team. What it’s about, Dr. Ripley underscored, “is really delivering a whole new toolbox to take care of patients.” Changing healthcare for the better and truly helping patients is the bottom line for the VA, and 3D printing is bringing a new dimension to that care.

The technology is coming into use for “all kinds of surgeries,” helping medical teams to communicate between specialties and with patients. Radiology imaging is well-known to be hard to read; 1500 two-dimensional slices of a three-dimensional anatomy are only really helpful to those who have been trained to read them. Building this puzzle in your head and trying to understand it can be a challenge, Dr. Ripley said; “That’s my job as a radiologist, but I had to go to school for longer than I cared to remember to understand that.” Using words in written reports to the surgeon can lose something from looking at and understanding that actual intricacies.

“That’s where I started to get interested in 3D printing, to communicate better,” Dr. Ripley said.

Handing a jaw or a kidney or a heart to a surgeon allows for significantly faster communication and understanding — to say nothing of what this conveys to the patient whose anatomy is being discussed.

“We just gave a model of a kidney to a surgery team. Another great thing about the VA is we’re a teaching hospital — not only are the patients benefiting, but the residents and fellows and future doctors and nurses all coming through the VA too,” she said.

“This surgeon came and he’s had about seven different cases printed for him, but his team’s all brand new residents and they’d never seen it. It was really cool to grab the kidney, show the entire team, and be sure they were all on the same page and understand what’s happening within minutes. They’re the ones going to help operate, and do that in the future. That ability to fast-track the transfer of knowledge and teaching and understanding the art of medicine is also a very large component and something really special about VA adopting this.

“It’s so cool to give to the patients, and they can have really meaningful conversations with their medical teams.”

All the benefits already coming into the operating are huge and exciting — and nothing compared to what might come next. Whatever that is.

Now, Dr. Ripley noted, everyone involved in medical care is an inventor:

“Every staff member, every patient even, can invent something that could totally change medicine. And it can happen, we have all these ideas in the hospital now, which we never could do before.”

Researchers and engineers “embedded in every hospital” are also boosting the VA’s use of 3D printing. VA Puget Sound, where Dr. Ripley is based, hired its first 3D printing engineer earlier this year, and she noted that he has already been a huge asset.

The interlinked nature of the VA health system also leads to what Dr. Ripley referred to as mind melds and force multipliers; sharing and communicating innovations, drawing on established expertise, and digital transfer of information and design “allows a veteran to be taken care of by the best doctor or orthotist or prosthetist in our system, so we can match a patient to the right expertise and always print the thing locally.”

“The biggest point really is that as that large integrated healthcare system, VA really is in that position to advance change and positively disrupt the way that we take care of patients. And 3D printing is a huge part of that,” Dr. Ripley said as we closed our chat.

“It’s important for us: our mission is to take care of veterans. That is our one and only mission and we want to deliver world-class, cutting-edge care and 3D printing is helping us do that. I won’t be happy until we can take care of all nine million veterans, so expect to hear more great things with incorporation of 3D printing across the VA and great things our staff comes up with next.”

Read part one here.

Via Stratasys and VA Puget Sound Health Care System