![[Image via BigRep]](https://fabbaloo.com/wp-content/uploads/2020/05/unnamed-6_img_5eb09dcbd8506.jpg)

We get a look inside First Man’s use of 3D printing.

Nearly a decade ago, we thought that 3D printing might make its way to that most gilded of Hollywood recognitions: the Oscars. Now nominee First Man is awaiting that red carpet day to find if its team will be among those collecting their statuettes. The movie is nominated for Best Visual Effects, and some of those effects blasted off (as it were) thanks in a big way to 3D printing.

The large BigRep ONE was one of the first installations in the film’s pre-production workshop, we’ve learned, as BigRep America President Frank Marangell shares a closer-to-the-action perspective. Marangell and his team worked with First Man Production Designer Nathan Crowley to create some iconic replicas.

“By getting us involved early on, Nathan and his team were able to use BigRep 3D printers to produce many of the components that were used in the film,” Marangell tells Fabbaloo.

While Crowley and his production team were familiar with 3D printing technology, the larger formats enabled with the BigRep ONE created new possibilities. While of course there’s a learning curve with any new technology brought into play, the crew were able to scale up from their desktop 3D printer experience to BigRep’s large-scale machines with relative ease, Marangell continues:

“Even though the First Man team hadn’t used them previously, it took very little time before they were working independently and creating amazing props that transformed into those powerful images seen on the big screen.”

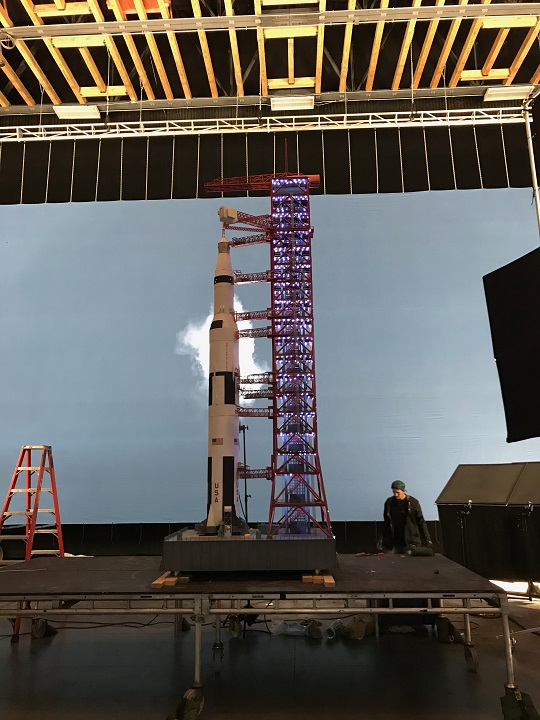

Among the 3D printed replicas that helped bring first man on the moon Neil Armstrong’s story to the silver screen were the Apollo 11 capsule and its dashboard components, a replica of the Saturn V rocket, and the Lunar Exclusion Module. The replicas, created on the two BigRep ONE machines the team leased, offered physical pieces for the film that would otherwise have been fully created in CGI. The real thing captures more detail and realism — helpful for a biopic showcasing real events, real people, and real technologies.

The process took about half a year of design, production, and installation for the set pieces. Use of the large-format 3D printers allowed for more timely creation of the large-scale replicas that were created. In the images below, provided by BigRep, the full scale of these models can be seen:

“Our German-engineered 3D printers are the largest industrial machines on the market, and that was critical for the First Man team,” Marangell tells us. “Consider the size of some of the parts they were printing. Attempting to do that from a smaller machine would have required exponentially more post-processing work that would have sacrificed the structural integrity of the pieces. If you want to print large pieces, you need a reliable 3D printer capable of producing high quality parts – made for the big screen.”

3D printing and special effects for movies and TV shows have, by now, a storied history. Should First Man take home a win in any of the four categories in which it was nominated, it will be a worthy achievement — but not a first. 3D printed special effects have already led several endeavors to recognition as they enable expressions and full characters, detailed props, more flexible physical set pieces and costumes, and even futuristic visions — all as the technology unlocks creativity and helps bring filmmakers’ visions to life.

Via BigRep