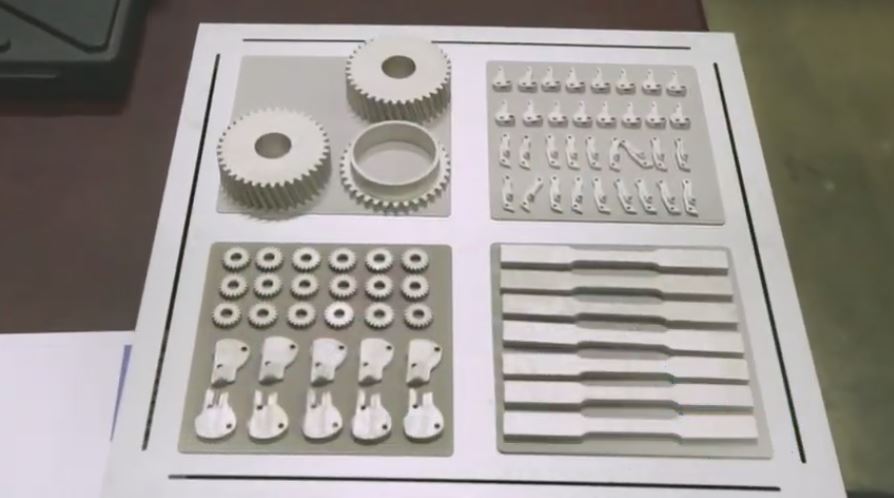

![Fresh-made metal parts [Image: 3DEO via YouTube]](https://fabbaloo.com/wp-content/uploads/2020/05/3deo_img_5eb09b5924607.jpg)

We recently caught up with LA-based 3DEO for an update on the latest in metal 3D printing and the company’s celebration of a diverse workforce.

“In 2019, our emphasis is really rolling out a quality campaign in terms of quality around additive manufacturing and what needs to happen,” 3DEO President and Co-Founder Matt Sand told me.

If there’s a major focus this year for the busy metal 3D printing company, it’s “quality.”

“Quality is a big barrier to further adoption of AM especially in production,” Sand continued.

3DEO is focusing on production capabilities, where quality is of the utmost concern. Direct work with customers and close relationships have made the company keenly aware of the direction they need to go to make metal additive manufacturing competitive.

In 2018, they shipped over 30,000 production pieces. That number is due to rise significantly this year, as the company has already taken two massive orders, one for 24,000 pieces and another for 28,000 pieces. And that’s just two customers.

“When it comes to volume serial production in additive manufacturing, we’re really happy about our process,” Sand said mildly.

The company works with “all kinds of different orders” as Sand noted work in the demanding medical and aerospace industries, as well as defense, military, police, and more to come as they go along. And all of these will be “in MIM type quantities of 25-50,000” pieces, he said, as they see metal 3D printing as being directly competitive with traditional manufacturing.

A sticking point for metal 3D printing has also been cost. While one-off pieces and custom orders have proven their value, serial production still has a ways to go in terms of cost competitiveness.

“You’re not even at the table if you’re not close on cost,” Sand continued. “If you can be close on cost, you’re at the table, and you’re competing against some of the highest-quality manufacturing technologies in the world. We routinely compete against CNC machining in lower volumes and MIM at higher volumes. Competing on RFQs is really exciting for us.”

As 2019 picks up steam, Sand noted that many predictions are that this year and 2020 will be “the years of production in additive manufacturing — and we definitely agree.” Quality, quantity, and cost are critical when it comes to serial production.

The business model at 3DEO is interesting; as Sand describes it, “We ship parts, we don’t sell machines; we’re a service bureau but use our own technology.”

To sustain the growing numbers of sales, the company is more than doubling its production capacity. In January, 3DEO had 8 printers working, with plans to go up to 20 production printers in 2019. With each 3D printer averaging 1,000 parts per day, “our capacity for 2019 will be pretty significant,” Sand added.

3D printing industry veteran and 3DEO advisor Cathy Lewis pointed to some of the other unique facts of the company’s operations as we spoke.

“Most companies installing the equipment are talking about a two-year period to ramp up. We can help them get there, pick the parts, get them into production with series manufacturing, and they have time to really evaluate the technology and pick the right technology for themselves,” she said.

Ultimately, both agreed, the importance lies in the finished products.

It’s not how the parts are made, but how they work, that truly matters to the end user. To make those parts, the team behind the technology needs to be solid as well in quality and quantity.

Additions to the 3DEO team, including COO Marty McGough, have been adding focus to the quality story the company tells. McGough, Sand noted, has “been involved in some of the biggest success stories in the industry,” as he worked with quality at Align Technologies and for hearing aids with Siemens. Focusing on metal now with 3DEO, McGough also noted of his appointment that it was the team that attracted him to work with the company as he moved from advisor to COO.

An important part of the ethos at 3DEO is tied to that messaging of team, as the company is today among those celebrating International Women’s Day.

“To maintain this rapid growth, 3DEO is committed to building the most qualified and diverse team from all backgrounds. 23% of 3DEO’s team is comprised of women, with roles ranging from manufacturing to marketing,” the company notes in an announcement honoring today’s occasion.

With the overall 3D printing industry comprising 11% women employees globally, 3DEO is showcasing commitment to its team building. Sand notes that the company believes “in diversity and equal opportunity.”

“Our female workforce has been an integral part of our success to date. Recognizing the valuable contributions of the women on our team, we consciously work to foster a culture of inclusion. This team diversity is central to our core values and meaningfully contributes to our competitive advantage,” Sand said.

The company is sponsoring this month’s Women in 3D Printing event for the LA chapter, to be held 6-9pm on March 21.

Via 3DEO

1 comment

Comments are closed.