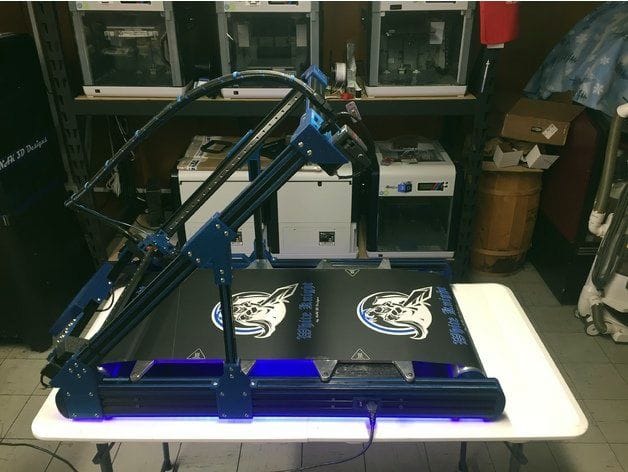

![The White Knight belt 3D printer [Source: Thingiverse]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0997fc8937.jpg)

The White Knight 3D printer is one of a long line of 3D printers developed by need.

Pennsylvania-based Karl Brown of NAK 3D Designs has been working with 3D printers for years and has developed a design for a rather large belt-driven 3D printer.

If you’re not familiar with the belt-printer concept, it is quite brilliant, but at the same time difficult to produce.

Normally most 3D printers use a cartesian coordinate system to locate the moving parts of the system within a fixed volume in the shape of a cube. Thus you will see specifications such as a “build volume of 100 x 100 x 100 mm”, and similar. But belt systems are a little different.

Instead of 3D printing within a cubic volume, they instead take the X-Y plane and tip it to, say, 45 degrees. Then the Z axis is implemented by a moving belt. It’s a bit hard to visualize, but I’ll give you an analogy that might help: Imagine a box of cookies, one that has a single “column” of cookies. Now, open one end of the box and slide the box to the side, allowing the cookies to emerge. That’s essentially what a belt 3D printer is doing.

![Joel Telling catching a print coming off the White Knight 3D printer [Source: 3D Printing Nerd]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb09980004f1.jpg)

This approach has multiple significant advantages:

-

The Z-axis is effectively infinite, meaning you can 3D print enormous models in one print job.

-

As completed prints roll down the belt, they eventually peel off automatically when they reach the end of the belt, thus eliminating the work of print removal.

-

The belt system can run continuously, or as long as it is supplied with input material, meaning low-volume production without almost any human labor required.

I can testify to these advantages, which I enjoyed as many years ago I was one of the few who undertook the MakerBot Automated Build Platform, a conveyer belt system that attached to the their then-current machine, the CupCake. It worked extremely well, as above, at least until the belt warped from thermal effects.

Brown’s design is rather large, with a 400 x 430 mm X-Y printing area, and an infinite Z, of course. You could, for example, 3D print an object, say, 380 x 400 x 1450 mm in a single job run. That’s big!

You can see a bit more of this machine — and Brown himself — in action in a video by our friend Joel Telling in this recent video:

Brown and his company NAK 3D Designs offers the White Knight as an open source design, downloadable at no charge from Thingiverse.

What’s of interest to me is the motivation behind this design. There seems to be two triggers for his efforts:

The demise of Printrbot meant the end of a new design being worked on by that former company, the Printrbelt. This was a belt-driven design that offered all of the advantages listed above — but is evidently no longer available.

Secondly, the emergence of a new belt 3D printer, the Blackbelt. We’ve seen the Blackbelt 3D printer in person, and it most definitely works, and works very well.

But if the Blackbelt is available for purchase now, why spend the effort to develop an alternative design? It turns out the price of the Blackbelt is the challenge for Brown. Blackbelt has set the price of their unit at €10,000 (US$11,400), which is far out of the range of any hobbyist, and much more than the now-dead Printrbelt.

![The White Knight belt 3D Printer [Source: Thingiverse]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0998029609.jpg)

Brown’s design — as it is not a product or even a kit — can be made by skilled technicians by obtaining the parts for something less than US$2,000. That’s a significant price drop, but you’re trading the work to source parts, build and set up the White Knight.

I suspect that Blackbelt set their price based on the expectation that industry would be attracted to the production aspects of a belt-driven 3D printer, where the machine could potentially make good money by performing low-volume production for clients. That revenue could justify the high price of the Blackbelt machine.

However, Brown is targeting his concept at the DIY community, where it may also be successful. However, US$2,000 is a fairly steep price for many hobbyists, who make not even be able to afford the parts for the device.

An update this week also indicates that we may also soon see a kit version become available, as NAK 3D Designs has teamed up with Printed Solid:

I am pleased to announce that due to the overwhelming positive response to the White Knight Belt Printed, NAK 3D Designs and Printed Solid have formed and alliance to bring the community a kit version of the White Knight. Stay tuned for future announcements.. pic.twitter.com/b2aIB4h2kq

— NAK 3D Designs #WhiteKnight #ERRF2019 (@NAK3DDesigns) April 7, 2019

But for those who can afford it and prefer not to wait, the White Knight is ready now for download.

Via Thingiverse

FELIXprinters has released a new bioprinter, the FELIX BIOprinter, which is quite a change for the long-time 3D printer manufacturer.