I recently spoke with the folks from Dyndrite, who intend to replace the very heart of 3D printing: the 3D kernel.

Dyndrite, which is pronounced “den drite”, is a software company based in Seattle. It’s a startup company, having launched about five years ago — but only emerging from stealth last year. Their work is a bit obscure and will require an explanation, but be aware their products will be quite revolutionary. In fact, two of the company’s notable investors include Google and Carl Bass, former CEO of Autodesk.

Dyndrite is working to resolve one of the most difficult, yet hidden issues in 3D printing: performance. Somehow we’ve all become accustomed to slow performance where operations take incredibly long times to complete, or even no performance at all when software overloads and fails miserably.

To solve the performance problem, Dyndrite is building an entirely new geometry kernel.

Wait, What’s a Kernel?

In software, a “kernel” is the fundamental core of the system from which all other services and activities are drawn. According to Dyndrite, the last time this was truly done in the 3D world was the 1980s, and that’s now a long time past.

They believe most of today’s 3D performance issues result from the use of now-outdated base software, and their hope to replace that with their high-performing kernel.

It’s not an end-user product per-se, but instead is a component upon which others can build high-performing 3D software.

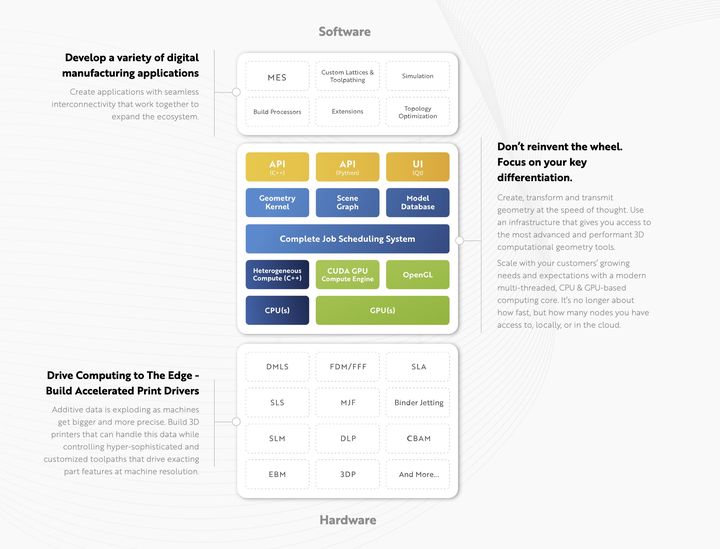

As you can see in their software component diagram, they provide a layer of features that allows applications to easily integrate with modern hardware, including GPUs, which have recently provided a tremendous power boost to software that can gain access to it.

End-user software needs only tickle the appropriate APIs (application program interfaces) to make things happen. These base functions are highly optimized by Dyndrite and the result is far faster applications.

Dyndrite Speed

How much faster? Dyndrite explained to me two recent examples where they were able to optimize 3D print slicing operations. In the first example, a job that took 12 hours to complete using normal software took only 15 minutes using Dyndrite’s kernel on the same hardware.

In another example a job previously taking a monstrous 67 hours to complete was done in only two hours using Dyndrite’s kernel. That’s incredible!

The kernel is not just usable for toolpath generation, as the APIs are suitable for use in a wide variety of 3D functions, including generating lattices, simulations, topology optimization and similar. All of these increasingly common functions suffer from generally terrible performance on most platforms. It’s even forced many users to acquire high-end hardware to compensate, and that may be reduced through the use of Dyndrite’s kernel.

Dyndrite Future

I anticipate that the need for these performance improvements will only increase in the future, as we increasingly see more and more complex 3D designs, each of which will face a performance barrier at all stages of their development and processing.

The added performance could have a number of profound implications on 3D printing.

One is the possibility of major changes in tool paths. Today we see fairly standard tool paths developed by slicing software, but if you’re like me and observe a print job in progress, you want improvements. I can’t tell you the number of times I think, “wait, it would be better if the path went THAT way instead!” This type of intelligence could be baked into future slicing systems using Dyndrite’s kernel.

Another possibility is to make 3D printers themselves a lot smarter. Today much of the processing takes place outside the machine on desktop PCs because of hardware requirements. However, what if the software was far more efficient? Could the kernel be placed directly into a 3D printer so that it could perform its own processing? Could future 3D printers slice jobs on their own? Perhaps we may see CAD files, with their juicy internal meta data, transferred directly to 3D printers and avoid slicing software entirely.

One trend I’ve been seeing recently is the dramatic increase in the use of real-time sensors in 3D printers, which allow more direct control of events and the environment to produce much better quality results. Now imagine a world where 3D printers have many, many times more sensors and a fast-performing software engine to handle them. We could see significant improvements in print quality.

With a performance boost of this magnitude, we may see designers attempting vastly more complex designs that are essentially unimaginable today due to processing constraints. If those constraints were removed we may see some very interesting developments.

Dyndrite seems to be making good progress on their product, and has gained endorsements from a number of notable companies in the 3D space, including:

- 3D Systems

- Aconity 3D

- ExOne

- AON3D

- Plural

- Altair

- Desktop Metal

- Impossible Objects

- Aurora Labs

- Renishaw

- ANSYS

- HP

- EOS

- NVIDIA

- SLM Solutions

Dyndrite feels we’re at the “dot matrix” stage of 3D printing, and their software could lead the way into the “laser printer” era. This could happen, and I’m excited to see how they progress.

Via Dyndrite