Executives from RIZE connect the dots in the company’s newly announced 3D printer, depth of the RIZIUM Alliance, and what we can expect to see coming next.

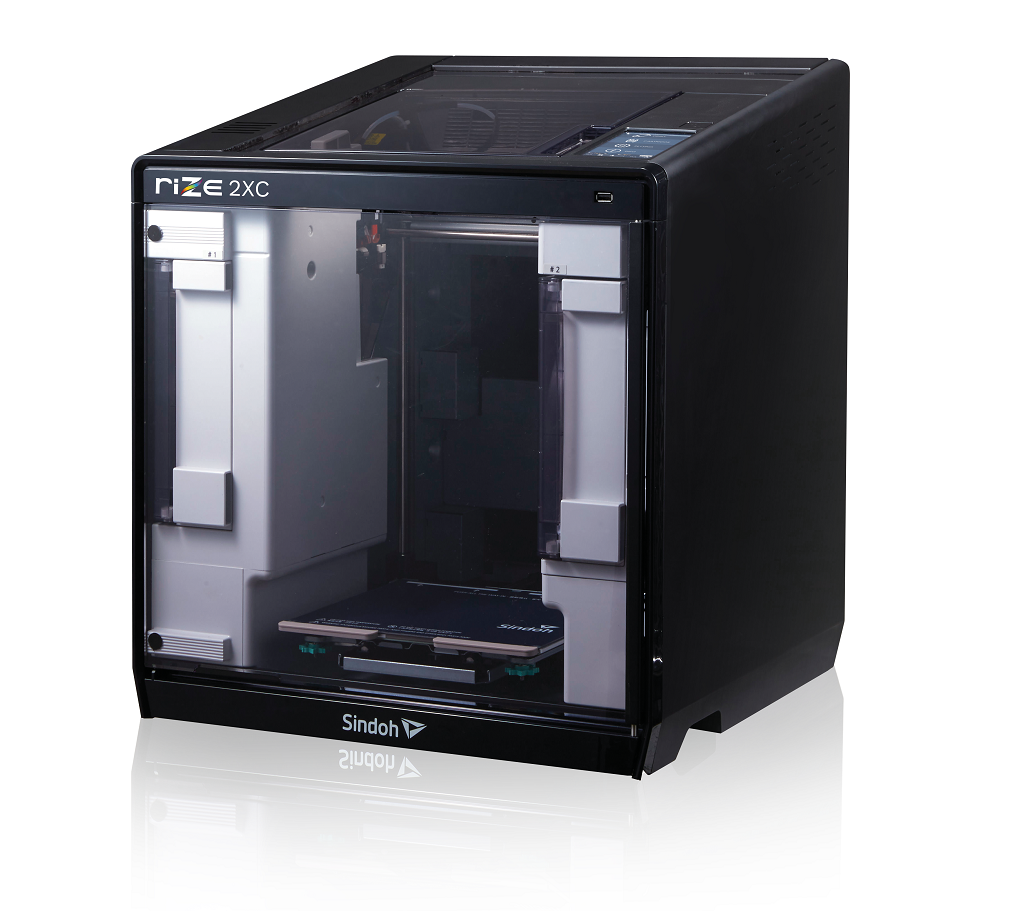

Ahead of today’s launch of the new RIZE 2XC 3D printer, I spoke with the company’s President and CEO, Andy Kalambi, and Founder and CTO, Eugene Giller. It sounds like RIZE will be keeping us busy as we look ahead to a “series of announcements” just beginning with the 2XC launch.

RIZIUM Alliance

We started with discussing the RIZIUM Alliance.

To begin, the partnership was introduced in February as a materials collaboration with South Korean hardware company Sindoh. As we can clearly see through the new 3D printer, there’s more than materials usage at play here.

“RIZIUM Alliance is all about helping the industry benefit from the materials science advances we’ve been doing,” Kalambi told me. “We are a 3D printing technology company and a materials science company — we’re more materials science-led than anything.”

While many may initially think of hardware when thinking of RIZE, associating the company with its RIZE One and XRIZE 3D printers, those more familiar with the company will well know that every introduction has layers of depth to it. When I first saw the XRIZE, for example, it wasn’t just about the colors advancements capable on the desktop 3D printer; we also spoke about why color matters and how it could meet customers’ needs — as well as the launches of RIZIUM CARBON and the RIZE CONNECT cloud platform.

We are even now seemingly scratching the surface of what the RIZIUM Alliance will enable, it seems.

“We created RIZIUM ONE, our first material, which was also the first material to be certified UL 2904 and still is probably the only one certified as zero-emissions and also USB Class 6, the highest for biocompatibility,” Kalambi continued of the company’s materials science efforts (read more here about their zero-emissions focus and UL GREENGUARD 2904, including Kalambi’s thoughts on GREENGUARD certification).

“These result from us engineering a material for a purpose. We design for strength, yes, which everyone is doing, but we want to also design for safety and durability — not even safety, sustainability. Within that is safety, recyclability, all those aspects. ABS and PLA don’t really lend well to certain things; they absorb moisture, they have problems with UV and chemical resistance, they are creating emissions. That’s how we designed RIZIUM materials. We also created inks that were designed for certifications and also got that UL certification. We then said, how do we ensure the industry gets the benefit of the safety mantra we have espoused?”

It was by asking this question that they began to work toward the RIZIUM Alliance.

RIZIUM materials currently include RIZIUM ONE and RIZIUM CARBON filaments. Soon, we will also see RIZIUM GF, a glass filled composite material suitable for full color applications.

“We are no longer keeping this close to our chest, we are partnered with industry here,” Kalambi said, adding that a formal announcement will be coming soon for the next RIZIUM material.

3D Printing In COVID Times

The plans for 2020 launches have certainly been impacted by the outbreak of global pandemic — though perhaps not at RIZE as much as other businesses may have seen.

The company, as so many in 3D printing have done, rose to the challenge of bringing technology to bear in creating much-needed personal protective equipment (PPE) for front line workers faced with significant supply shortages.

Giller showed one of the RIZE face shields, which was redesigned for air flow and to be very light. The use of CMYK inks also allows for personalization, which Giller noted partners quite like.

“This is also helpful from a safety point of view: this is your personal face shield with your name on it, which lessens cross-contamination. You know it is your piece,” Giller said.

“We are not unique here in creating face shields; we were part of that big community,” Kalambi added. “What we realized was that our teams working in their normal day jobs could also find time to work on these shields, and a few other parts, and nothing stopped for us.”

RIZE saw “not even a moment of stoppage” — which is definitely helpful when there’s a big product launch in the works, such as the RIZE 2XC planned with Sindoh. The partnership between the two companies was announced in February, just a month before most of the world saw significant shutdowns, and Massachusetts-based RIZE saw all of its workers move to home offices.

“It has been a very motivating time, even though it has been a very difficult time,” Kalambi said. “Our hearts go out. We have given out these shields; I was at hospitals during the peak in Massachusetts.”

The team are prepared to ramp back up should infection numbers go back up. But focus hasn’t been only on pandemic-response production for RIZE, which saw operations continue in an adapted manner.

“One of our learnings in these COVID times has been that people become so much more productive when you empower them and connect them into what’s happening the world around,” Kalambi said. “This whole way of working adaptively is something we want to enable through this technology and offer to the industry at large.”

While the RIZE team adapted to working virtually with the Korea-based Sindoh team to develop a new 3D printer, they also worked with the local community to ensure PPE production continued unabated.

“This is not competitive, but everyone did what was right for the community and not what was in their own interest,” Kalambi noted of the “enormous amount of commitment” as “the industry has been doing well in rising to the challenge.”

RIZE Updates

While the new 2XC 3D printer is exciting, and proved a central point of the conversation, RIZE does now have three 3D printers in its portfolio, so there’s always more to catch up on.

When it comes to the XRIZE, “we’ve made some amazing strides,” Kalambi noted.

“There’s a lot in life sciences, where we’ll be unveiling new applications; watch this space,” he said with a laugh.

“We are also working on a couple of new end-to-end solutions we call smarter workflows. Where we are going with these color parts is that we want more of these parts to be smart parts. The second thing we are doing is smarter workflows, to take the friction out, take non-value-added elements out of the workflows that drive 3D printing.”

RIZE recently held two webinars in a new Learning Series, including one titled “Build Intelligent Parts with Next Gen 3D Printing Platforms & Smarter Workflows,” discussing some of these smarter workflow concepts.

There’s much more to come in the near future from RIZE, and some of it sounds very intriguing indeed — more on that, though, when we can go on the record.

Wrapping up our conversation, Kalambi said:

“There are printers, and then there are printers. What I really want to highlight is the future of work, how we are going to stay productive in challenging times. This is an illustration of how this is done. You can be productive, you can contribute both to your work and beyond if you are properly enabled with the right technology. That I believe will remain as our learning well past these COVID times. If that is a message people can get, that will be well served for everyone.”

Via RIZE