We received notice that UK-based Photocentric has launched a battery research division.

Photocentric, if you are not aware, are one of the largest base manufacturers of photopolymer resin, a material used in virtually all SLA and LCD 3D printers. Their resin products are frequently white labeled and become brand names you’re familiar with.

Photocentric Businesses

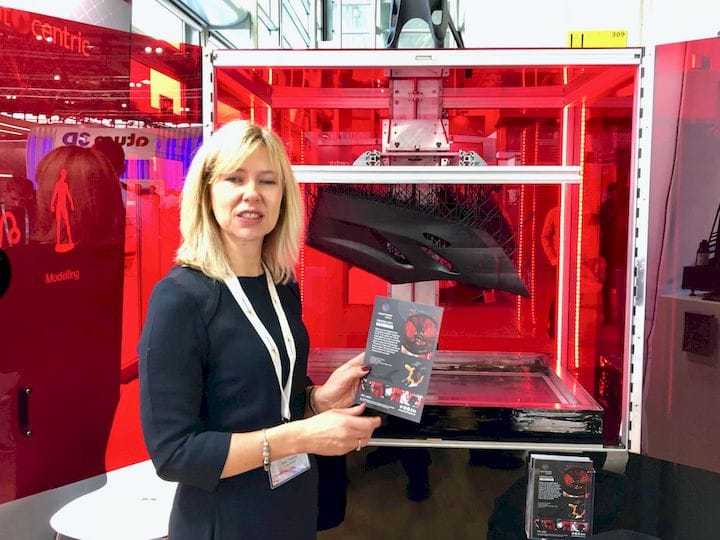

The company also began selling industrial resin 3D printers themselves some years ago as their unusual visible-light photopolymer resin was not well supported by the crop of third party resin 3D printer manufacturers at the time.

Their venture into 3D printer manufacturing was a big success, and I mean “big”: their most promising products turned out to be massive resin 3D printers capable of significant throughput. This capability turned out to be of surprising value during the pandemic, as their inventory of equipment was abruptly transformed into a PPE manufacturing center.

That experience caused the company — and others in industry — to realize that it truly was possible to use arrays of 3D printers for proper manufacturing uses. Thus they now have a general manufacturing business as well as 3D printer manufacturing and the original photopolymer resin business, too.

If that wasn’t enough, the company suddenly announced yet another unusual initiative, this time to 3D print batteries.

3D Printed Batteries

The concept of a 3D printed battery might sound a little strange, as we are all familiar with the printing of mechanical parts. Typically 3D prints are made of a mono-material that has little resemblance to the chemistry of a battery, but this view may change.

Batteries are a functional combination of structure and chemicals to facilitate the storage and issue of electrical energy. Electrons are stored within and released from the battery using cathodes and anodes, which turn out to require special attention.

There are many kinds of batteries, but all must be evaluated on several performance factors, and the specific requirements vary by application:

- Cost per unit

- Energy storage density

- Energy transfer efficiency

- Useful charge cycles

- Weight per electrical unit

For example, a vehicular application might require light weight and high density, but overnight solar power station storage might not care about weight or density.

These factors are strongly influenced by not only the chemistry of the battery, but the microstructure of the cathode and anode. I think this is where Photocentric might be headed. They’re in good company, however, as there are several other parties also investigating 3D printed battery technology.

Photocentric Batteries

Their equipment, like most resin devices, is able to 3D print objects in high resolution. It may be that they intend on adapting their technology to enable the production of advanced cathode and anode designs that have sophisticated microstructures. These would be specifically designed to address one or more of the concerns listed above.

Photocentric says:

“Photocentric are now focussing their entire research team on the issue of improving energy storage- one of the most important issues to face the Earth today.”

And:

“Photocentric are using novel additive manufacturing techniques to create lighter, smaller batteries to deliver faster charging combined with increased power density. It is hoped that this technology will enable orders of magnitude improvements in battery performance and be used in a future Giga factory based in the UK.

Photocentric consider this to be the most important research project they have undertaken in their 18-year history. They are using their novel visible light polymerisation in combination with their LCD screen-based 3D printers to enable the low-cost mass manufacture of batteries and have several patents filed in this area.”

That’s a very strong move by the company: dedicating their ENTIRE research department to this single area. This means their work advancing resins used by clients may not notably improve in future years, so they must have some significant goals in mind with this project.

It may be they have discovered something in the lab that they are confident they can refine into an important product in the future. Of course, we don’t know what that is, at least not yet.

At this point there is no other news from them, as they seem to have just begun this project. But I’ll be watching carefully to see what develops.

Via Photocentric