3D printing software is smartening up its slicing as Teton goes live with its first product: Smart Slice for Ultimaker Essentials.

We first encountered Teton Simulation Software last spring, when the company shared a look at their intelligent slicing automation solution. Since that first conversation, we’ve also had the opportunity to test out their Smart Slice tool in Cura (it works!) — and we were delighted to hear the full launch was happening this month.

Ahead of the launch, I spoke with the Teton Simulation team for more background.

Teton Simulation Software

“We’ve been working on this technology for four years and now we’re actually going to launch it,” CEO Mike Kmetz opened with a smile. “What we’ve developed behind the scenes is a really sophisticated piece of technology — and the beauty of that is that the user will never be aware of that. With just a few clicks, and information about your job, it does all the work.”

There’s just “a little pause” while the smart slicing tool does all the work automatically, and then “it helps you develop a better 3D printed part,” he said. This “solves a nagging problem in FFF 3D printing” — which, for now, is the 3D printing process Teton is targeting.

Additional processes may come into play in the future, based on user demand, but for now all focus is on FFF: “specifically Cura.” We can, though, Kmetz teased, also expect other partnerships to arise; “Just as Ultimaker has taken a real interest, we’ve seen the same enthusiasm from other partners,” he said, adding that these are “major machine companies.”

The primary drive behind introducing Smart Slice is user friendliness in achieving optimal 3D printed parts.

“What we’ve discovered from talking to a lot of people is, if you have a 3D printed part that has to solve some real-world requirements, say it has to have a certain strength or stiffness, it’s really hard to determine through the settings in your slicer what those should be to have a well-behaving part. Companies often have an expert in-house to set parameters and test them; we’ve been told by companies that they’re iterating on those parts from five to 50 times,” Kmetz continued. “Think about that in terms of cost: there’s print time, material utilization — you’re looking at a lot of costs if you’re iterating five times on a 37-hour print job.”

Instead, Smart Slice can do those iterations for you — digitally. That’s no print time, no material use, no post-processing to check a part.

“We don’t speak FEA [finite element analysis] to our audience; we speak in terms of, we have a tool that runs in Cura, and runs extremely quickly, that provides excellent results,” Kmetz said.

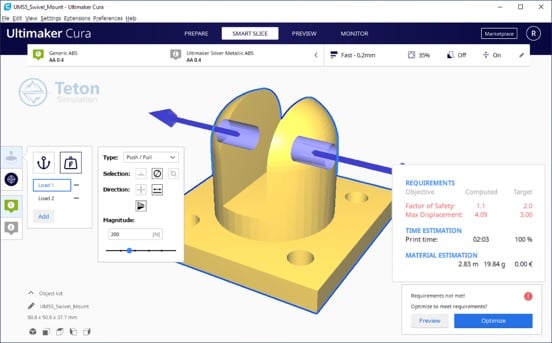

Rather, that is, than spend 37 hours in a print job that may or may not provide the results desired, “literally in a minute or two you can run that in Cura.” If that iteration doesn’t fulfill your specs, “maybe adjust the settings, the infill or walls, or just let the software do the work with Optimize,” Kmetz said.

The sophisticated Optimize algorithm may take up to two hours — but, again, that’s not 37 hours of 3D printing. Once the part has been run through this algorithm, it will have been optimized for production in the shortest print time using the least amount of material to still meet all requirements.

Smart Slice for Ultimaker Essentials

The launch today is set to reach Cura’s massive installed base of users. The new offering will appeal the most, the Teton team thinks, to industrial users — fitting neatly with the users of the recently-introduced Ultimaker Essentials, which serves that industrial base of Cura users.

Teton describes the “pain-free workflow” as comprising three steps:

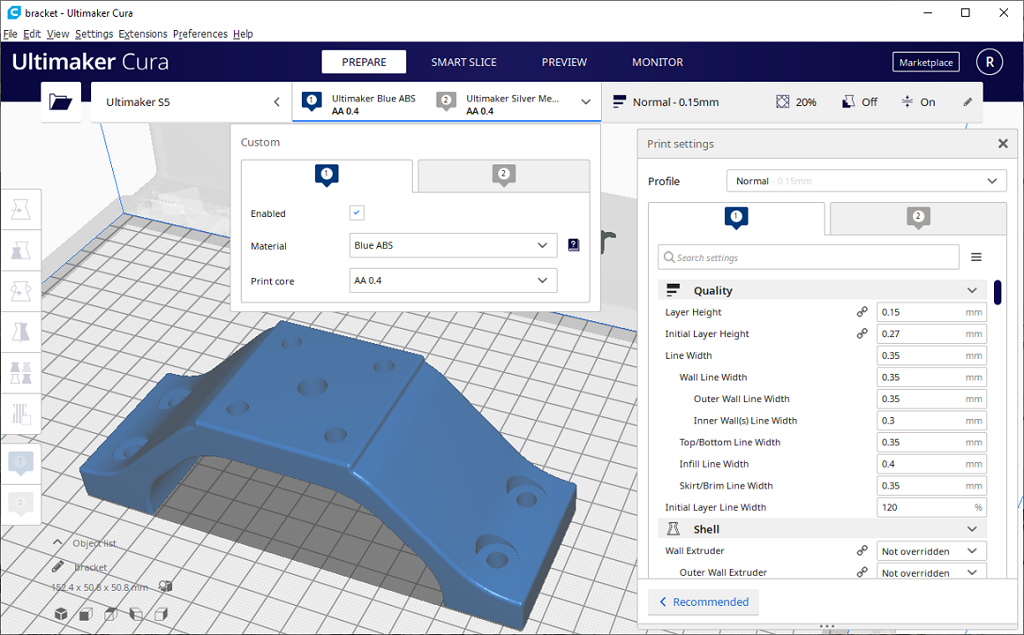

- Open your part in Cura, select a material, and enter the Smart Slice stage.

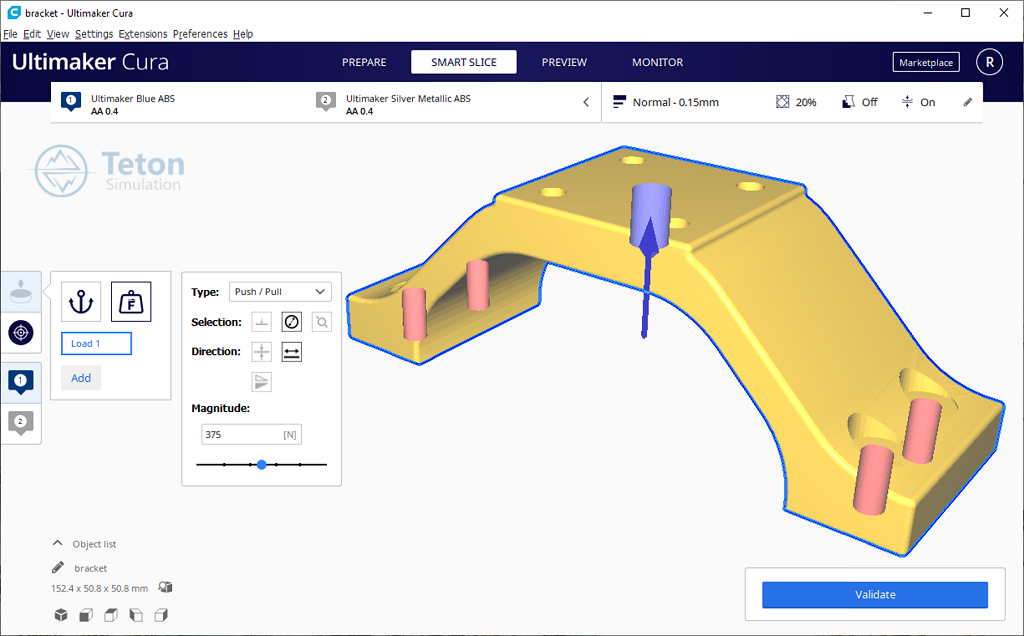

- Define use cases and requirements. Then, it’s as simple as 1-click validation and optimization.

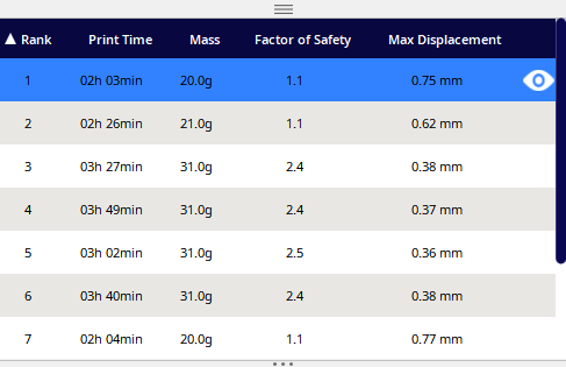

- Choose from a ranked list of recommended profiles. Preview, then print your part.

“Teton’s Smart Slice brings engineering grade part simulation to Cura as an exclusive marketplace plugin for Ultimaker Essentials users,” says Paul Heijmans, Senior VP Software at Ultimaker, in today’s announcement. “Using the integration options of our open and pluggable platform it will make sure parts still meet their engineering criteria, but need less material and therefore saving valuable time and costs. The cooperation with Teton and the integration of their innovative solution are a prime example of how we will be continuously adding value for our professional customers.”

The subscription-based plugin is available now, and has an option for a 30-day trial basis through the end of this year. Introductory pricing is set at $495 per user per year, with multi-user pricing available.

Via Teton Simulation