It’s been brought to our attention there is a patent on a very unusual 3D printer extruder design.

Typical 3D Printer Extruders

A typical 3D printer extruder is a rather primitive mechanism that simply has a gearing system that pushes a filament into a hot chamber. The material softens and the incoming filament eventually generates sufficient pressure for the softened material burst out of the open nozzle at the bottom.

This process works, but is beset with a number of fundamental problems. Because there is no direct control over the extrusion — it works only by indirect pressure — you can have inconsistent amounts of extrusion. Another serious problem is oozing, where material in the hot chamber leaks out when the extruder is idle.

To counteract these problems, 3D print parameters are often tightly tuned, sometimes successfully.

The Rotary Extruder

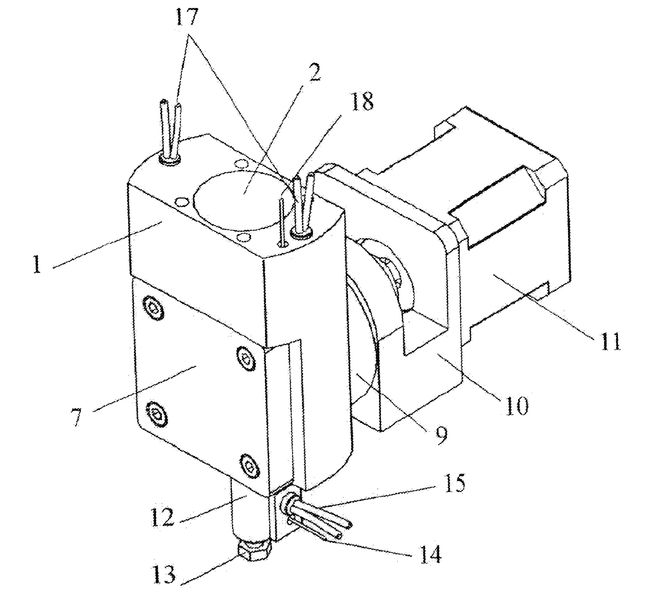

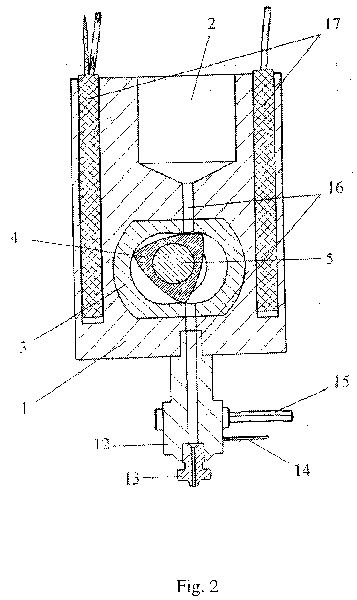

The rotary concept, invented and patented by Marat Sagimbekovich Temirbulatov, is called the “Rotary Piston Extruder” and that’s exactly what it is.

For the oldsters reading this, the best way to describe the concept is to say the core of the extruder is similar to the Mazda Wankel rotary engine from the 1970s.

The Wankel used a triangular “rotor” inside the engine that spun around a rounded chamber while running. This animation from Wikipedia shows how it worked:

In the Wankel system the energy was provided by igniting the fuel with spark plugs, as shown in the animation. However, it seems that Temirbulatov has adapted this concept for 3D printing.

In Temirbulatov’s version the rotor still exists, but is powered externally; there are no spark plugs on his design.

As the rotor turns, it grabs a fixed amount of softened material and expels it through the nozzle. If you look again at the animation you can imagine how this works, and it should be quite efficient. Each turn of the rotor would emit a known quantity of material.

This could directly control the amount of material being deposited without having to worry about the less-predictable chamber pressures.

There’s also an advantage in oozing: imagine if the rotor was positioned overtop of the nozzle exit when the extruder was idle. This would completely block the material from leaking, and thus eliminate oozing entirely.

It seems that Temirbulatov has been working on this concept since 2017, and received a patent from the USPTO on 20 August 2020, as well as patents from other patent offices.

It does not appear that the rotary extruder concept has been implemented in any commercial 3D printer, but it seems to me that it certainly could provide a significant 3D print quality advantage. It may also be faster than a normal 3D printer as well.

Similarity to BigRep MXT

Temirbulatov says (via Google Translate):

“Today I accidentally learned about the developments of the German company BigRep GmbH , in particular, they were interested in the extruder.

As it is written on the site, to the description of the BigRep PRO printer, they reinvented the extrusion technology and patented the technology of the MXT extruder-dispenser, but for some reason they patented as a trademark (trademark), and not an invention ??? The printer itself is good, a large print field, high print speed, etc.”

The rotary extruder does seem similar to BigRep’s MXT in some respects, as both systems produce fully controllable extrusions unlike any others in the industry.

I know that BigRep announced their MXT product long ago in 2018; we even had a story about the MXT extruder then. I also know that they had been working on the MXT for quite some time before then, based on discussions I had with BigRep staff.

It is a bit curious that BigRep has not patented their design, but there are valid reasons for doing so: if you patent a concept, it becomes public and anyone can duplicate it. If someone does, you have to chase them down with lawyers and demand licensing fees. Also note that these days it’s the “first to file”, rather than the “first to invent” that takes precedence.

Instead, some companies simply use the “trade secret” approach instead of a patent. In a trade secret scenario, the company simply does not publish anything about the mechanism and no one knows how to duplicate it. This is how the secret Coca-Cola formula works, or the Colonel’s “eleven herbs and spices” is protected. They are not patented, and it may be that BigRep has chosen the same approach here.

It is also likely that the two extruder designs are different internally. While they may have similar functionality, my understanding is that the MXT extruder has a toothed circular gear that grabs a fixed amount of material with each tooth. This is quite different from the rotary approach, so if it came down to a legal contest it may be a court would decide the two are different designs.

Regardless, I’d like to see how the Rotary Extruder actually works in a commercial 3D printer. It might turn out to be a very good option, and any professional 3D printer manufacturers looking to improve extrusion reading this story might want to contact Temirbulatov.

Via USPTO and Marat Temirbulatov (Russian/русский)