Last week Fabbaloo had a rare opportunity for an onsite visit to the not-quite secret headquarters of 3D Printing leader 3D Systems to speak directly with those in charge of engineering, sales and marketing. Located in the obscure city of Rock Hill, South Carolina, this is a place where 21st century magic truly occurs.

Last week Fabbaloo had a rare opportunity for an onsite visit to the not-quite secret headquarters of 3D Printing leader 3D Systems to speak directly with those in charge of engineering, sales and marketing. Located in the obscure city of Rock Hill, South Carolina, this is a place where 21st century magic truly occurs.  From the moment you enter the building, evidence of advanced 3D printing and manufacturing is everywhere. Seemingly every nook and cranny boasts amazing print samples of all types. Every cubicle and office displayed at least some prints, and a few cubicles were literally overflowing with amazing samples.

From the moment you enter the building, evidence of advanced 3D printing and manufacturing is everywhere. Seemingly every nook and cranny boasts amazing print samples of all types. Every cubicle and office displayed at least some prints, and a few cubicles were literally overflowing with amazing samples.  The centrepiece of their building is a startling windowed area in which the latest manufacturing equipment is free to view. On display are machines capable of incredible size, speed and resolution, using a variety of manufacturing techniques. Readers may be most familiar with their hobbyist Bits From Bytes line, but 3D Systems produces manufacturing and prototyping equipment all the way up to massively sized machines capable of printing an entire car dashboard in one go. We saw not only the BfB equipment, but also machines using SLA, SLS and other printing approaches.

The centrepiece of their building is a startling windowed area in which the latest manufacturing equipment is free to view. On display are machines capable of incredible size, speed and resolution, using a variety of manufacturing techniques. Readers may be most familiar with their hobbyist Bits From Bytes line, but 3D Systems produces manufacturing and prototyping equipment all the way up to massively sized machines capable of printing an entire car dashboard in one go. We saw not only the BfB equipment, but also machines using SLA, SLS and other printing approaches.  One of the SLS printers had just completed printing a child’s car seat. This item was not only full size, but it’s actually ready for immediate use. The materials used are sufficiently strong to safely support and protect a child. Our inspection confirmed this, as it appeared very strong. While this particular model is white, a quick coat of paint will make it indistinguishable from those you’d find for sale at the store. A look around the room showed several devices actively printing other direct-to-use objects.

One of the SLS printers had just completed printing a child’s car seat. This item was not only full size, but it’s actually ready for immediate use. The materials used are sufficiently strong to safely support and protect a child. Our inspection confirmed this, as it appeared very strong. While this particular model is white, a quick coat of paint will make it indistinguishable from those you’d find for sale at the store. A look around the room showed several devices actively printing other direct-to-use objects.  One very interesting sample was this shoe sole. It was printed in a soft, flexible material that is virtually indistinguishable from what you might find in any shoe store. Why is this so interesting to us? Because when you hold something like that in your hand, it proves that it is actually possible to print comfortable, usable shoes on demand. When we said 21st century magic, we weren’t kidding!

One very interesting sample was this shoe sole. It was printed in a soft, flexible material that is virtually indistinguishable from what you might find in any shoe store. Why is this so interesting to us? Because when you hold something like that in your hand, it proves that it is actually possible to print comfortable, usable shoes on demand. When we said 21st century magic, we weren’t kidding!3D Systems is now a billion-dollar company, at least according to their current stock market value, and it shows in the sheer size and breadth of their operations. We observed not only display areas, but also a large engineering department divided into relevant specialities, a secret laboratory where new magic is invented, sales and marketing, equipment manufacturing and administration. In all, some 150 people work at their HQ, and that’s not their only location. The folks we met were dedicated, professional, talented and most noticeable of all they were genuinely proud of the accomplishments they’ve made and continue to work on.

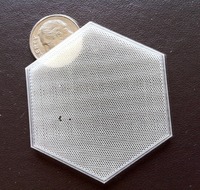

We examined a variety of sample printed models of astonishing quality. Some of the models were so finely resolved they were actually shiny. Another was hard to recognize at first, but it actually was a sieve – yes, a sieve! This item (click the image for full res and be amazed) contained structures so small you could hardly see them, truly demonstrating the power of advanced 3D printing equipment. There are actually two separate screen layers in the object.

We examined a variety of sample printed models of astonishing quality. Some of the models were so finely resolved they were actually shiny. Another was hard to recognize at first, but it actually was a sieve – yes, a sieve! This item (click the image for full res and be amazed) contained structures so small you could hardly see them, truly demonstrating the power of advanced 3D printing equipment. There are actually two separate screen layers in the object. How can they achieve these amazing results? It is, of course, a lot of hard work by many talented people. In fact, at one point during our visit we observed a table in the engineering department holding scores and scores of slightly different hollow cubes, each having secret codes written upon them. Yes, that’s right – they print calibration cubes too! It’s this experimental work that leads to the high quality results in their products. We’re hoping 3D Systems will somehow bring this level of quality to future consumer 3D printing devices.

The visit not only provided us the opportunity to see and touch many different 3D printing technologies, but also provoked a lot of thinking about where the industry might be headed in the future. Over the next week we’ll be writing up a few posts on both equipment and ideas. Stay tuned!