While home 3D printers typical heat/melt plastic to produce objects, Markus Kayser has developed an eco-friendly 3D printer for “desert manufacturing” using only sand as the print material.

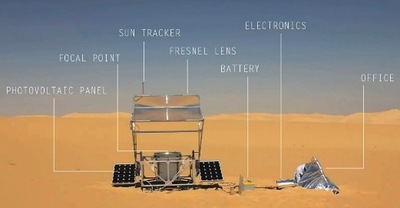

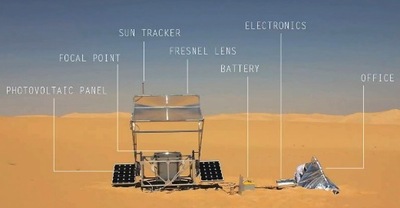

While home 3D printers typical heat/melt plastic to produce objects, Markus Kayser has developed an eco-friendly 3D printer for “desert manufacturing” using only sand as the print material. The Solar Sinter focuses the heat of the sun to a small point using a large, sun-tracking fresnel lens. The focal point is so hot it almost instantly melts common sand into glass. By moving the platform left and right, the hot spot transforms fine sand into a solid layer. Then by lowering the platform a touch and reapplying a layer of sand, the process repeats to gradually build up any object.

The two big advantages of this approach are: It’s solar powered – no external electricity required and (mostly) free print material, especially if you’re in the desert. That’s why we like this project – it may provide a way for desert dwellers to manufacture items without requiring funds for factory produced items. Another plus lies in the form of the print material itself: sand, as a powder, automatically provides support for object overhangs, meaning almost any shape can be produced easily.

However, we see some challenges as well:

- How well will electronics, belts and other mechanical bits stand up against the daunting weather found outdoors in the desert? It may be that such a device could only be used for a short while until it breaks or clogs up.

- Where do repair parts come from? Those who own 3D printers today often must repair their device, and sometimes this requires factory parts.

- The print resolution will be fairly coarse, depending on the lens. This means that only certain types of crude objects can be printed.

- The speed of printing is slow, as is typical with 3D printers. This implies that large-volume objects (like interlocking bricks for a construction project, for example) would not likely be feasible.

Nevertheless, we think Markus’ project is a great start on a new way to provide manufacturing for those in remote areas.