Hidden in the sleepy coastal town of Clevedon, UK, lies the secret factory that produces 3D Systems’ CubeX 3D printer. We recently toured the factory to find out how these popular machines are created.

Aside from a modest research and development unit, the entire facility is dedicated to production of CubeX’s. It is indeed a factory; we observed trucks delivering components at one end of the building, while other trucks (or “Lorries”, as they say in the UK) collected boxed finished units at the other end for shipment to points around the globe.

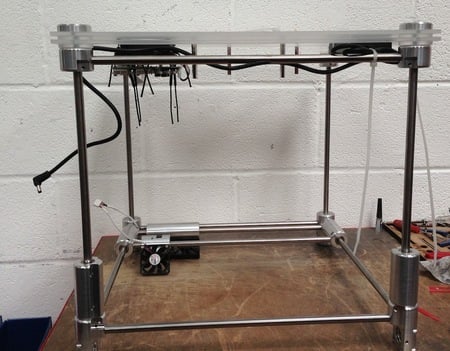

The process of assembly is straightforward, but precisely coordinated along the multi-stage production line. The first stage involves connecting basic metal components together to form the machine’s frame.

The frame travels along the production line where all the subcomponents are progressively attached.

Some complex subcomponents, such as the extruder, are pre-assembled by separate, dedicated teams to speed up the process.

While most of the machine’s components are delivered from distant factories, the metal components in the CubeX are actually manufactured right next door. A conveniently adjacent metal shop produces all the rods and other metal structures, simplifying the supply chain significantly. We’re told the metal shop’s proximity is also very handy when new prototypes are developed.

Once a unit has been completely assembled, work has not finished. Each machine then moves to a test area where it undergoes rigorous testing and calibration. Specific test prints ensure each machine works correctly. If not, the machine is diagnosed, repaired and recalibrated until it passes certification tests.

Machines then move to Quality Control, where the machine is cleaned, inventoried and checked one last time. The final stage, of course, is packing and shipping.

We were impressed with the efficiency of the CubeX factory; it is well organized and has appropriate assembly line process optimizations. We had a strong sense that the managers were constantly evaluating the assembly process to introduce improvements when identified. But the true test of any factory is the resulting products, which in this case are high-quality CubeXs.