Stratasys made a big splash earlier this year with their new tricolor Objet500 technology. Now they’re expanding the technology to two new 3D printers.

The Objet500 Connex1 and Connex2 3D printers use the “triple-jetting” technology previously introduced in the Connex3. We’re not exactly certain how the machine numbering system works, but nevertheless, the two new machines are quite interesting.

The Connex1 is similar to the Connex3, but has a much larger build capacity. While the build volume is identical to the Connex3 (490 x 390 x 200mm), the Connex1 can now handle up to eight material resin cartridges at a time. This means the machine can print for much longer periods in an unattended mode. It was possible to swap cartridges on the fly before, but the new capacity means you might not have to come back to the machine on the weekend for a very long print.

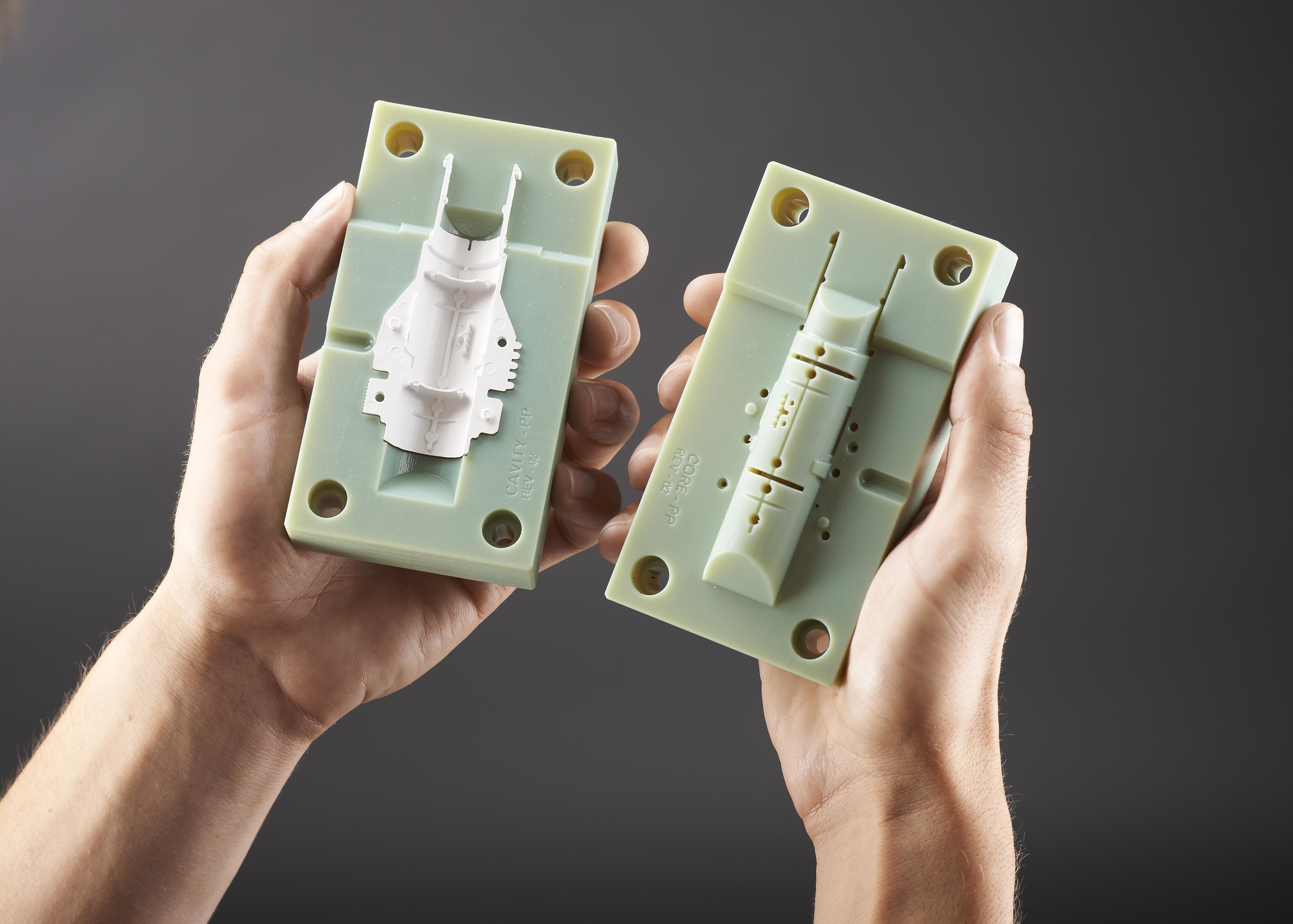

The Connex2 is again very similar to the Connex1, but it has the added ability to digitally mix materials during printing. For example, you could mix hard and soft material to create multiple different grades of hardness, all within the same print operation. The Connex1 evidently cannot digitally mix materials. Due to this capability, the Connex2 can use Stratasys’ Digital ABS material, that can be used to print usable mold cores for injection molding. We’ve seen this in action and it really works – and is less expensive than creating molds in traditional ways. Stratasys offered a two-material machine previously, but the Connex2 can have three materials ready to print within a single print job.

The two new machines are extensions of the original Connex3 machine announced earlier this year. We suspect the changes may have to do with customer experience on the Connex3 – it may be that companies were printing very large items and wanted to reduce their operational staff costs by reducing off-shift requirements. Another possibility is that tri-material printing doesn’t necessarily use all materials equally, much like printing 2D photographs. Resins will be used unequally and therefore it’s possible Stratasys realized there’s a requirement for additional capacity.

We believe the new machines are steps toward the “ultimate” resin machine, which would hold a full complement of colors, transparency and rigidness, which we wrote about earlier.

Via Stratasys