GrabCAD and NASA announced what could be the grandest 3D printing challenge ever: win and your design goes into space!

The contest is a kind of crowdsourced experiment to further testing of the already in-orbit 3D printer from Made In Space. So far, the space station crew has successfully printed a series of standard test objects and even an emergency wrench required by an astronaut.

Now NASA wishes to push the envelope of understanding a bit further by printing an object for daily mechanical use inside the station. They’re hoping to identify the most effective design, which will tell them much about the right and wrong ways to 3D print functional objects in micro-gravity.

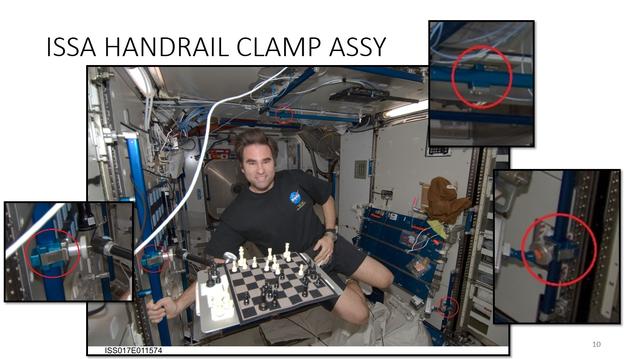

The specific challenge is to design a replacement “seat clamp interface”, which attaches to a handrail that runs throughout the station.

The prize “pool” is USD$2,000, to be split among the top five designs as selected by a judging committee composed of NASA experts and GrabCAD staff.

There’s two other fascinating aspects to this challenge: design goals and requirements.

The design goals for the seat clamp interface are a little different in order to meet the needs of orbital 3D printer operators. They specify, for example, a maximum amount of plastic to be used to minimize outgassing within the contained atmosphere of the station. They also require a design that is as near failure-proof as possible to minimize astronaut labor.

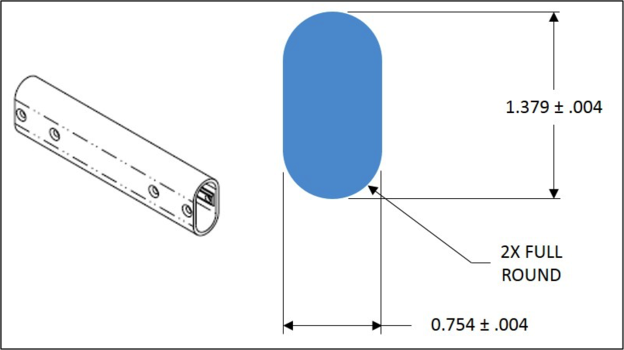

The requirements are also interesting in that they’re extremely detailed. Although they are far less than one might expect to find in a typical NASA spec sheet for rocket parts, they’re very detailed compared to what you’d encounter in other 3D print contests. An example:

3. Shall conform to the following sharp edge human factors

– Exposed edges 0.25 in thick or greater shall be rounded to a minimum radius of 0.12 in.

– Exposed edges 0.12 to 0.25 in thick shall be rounded to a minimum radius of 0.06 in.

– Exposed edges 0.02 to 0.12 in thick shall be rounded to a full radius.

– The edges of thin sheets less than 0.02 in thick shall be rolled or curled.

It’s expected that designs of interest to NASA will actually be printed in orbit to determine if the designs work in the ways expected.

This contest could prove very popular. Even though the contest has just begun, there are a couple dozen entries present, with many more expected. It could be difficult for NASA to select winners.

You may never get to space yourself, but now it’s possible your designs might. If you wish to go into orbit by proxy 3D print, please enter GrabCAD’s contest before it closes on February 17th.

Via GrabCAD