There have been many announcements of resin-based 3D printers recently, but this one is a bit different: the Morpheus 3D printer smashes two major problems.

Resin 3D printers have been long desired by many due to their ability to print with incredibly fine resolution, but adoption has been tempered with two key issues: typically the print volume is quite small and secondly the print speeds can be slow, particularly on laser-based equipment.

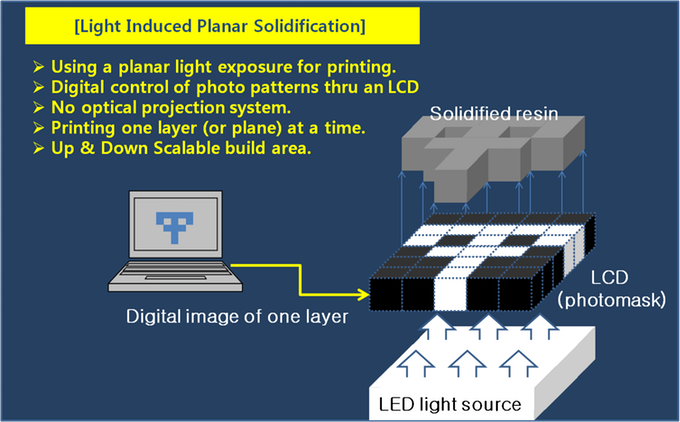

The new Morpheus 3D printer from Korea-based OWL WORKS gets around those problems by using a new approach to resin-based 3D printing, which they call “LIPS” (Light Induced Planar Solidification).

Let’s first look at how most other resin-based 3D printers work. Typically a UV laser laboriously traces out the solid portions of each layer, which permits larger builds, but at the cost of print speed. The other typical approach is to use a DLP mechanism to shine an array of UV pixels on the liquid resin surface all at once to solidify a printed layer. To gain more accuracy, DLP machines simply use lenses to focus the same number of pixels on a smaller area, creating higher resolution, but at the cost of build volume.

OWL WORKS’ new LIPS process gets around both problems. It works by planting a full size LCD panel at the bottom of the resin tank, where it can illuminate all parts of a layer at the same time. The resolution of a layer is literally the same as that of the LCD panel. There is no “down focusing” to gain resolution.

This also speeds up printing somewhat. The company states their print speed as being between 10 and 35mm per hour, which is decently fast. However, there is a hidden speed advantage we’ll describe in a moment. A side effect of their process is that the machine never requires calibration.

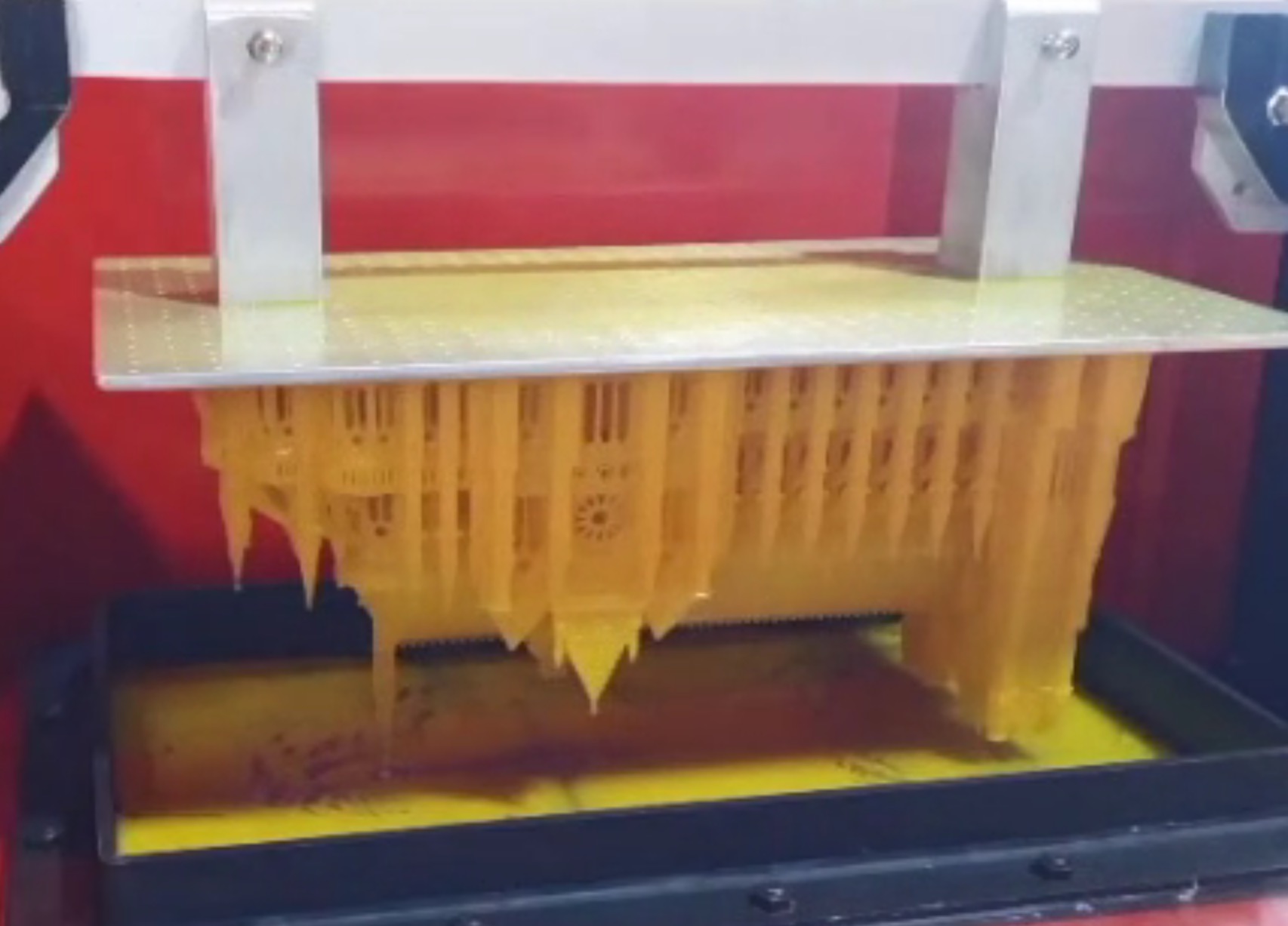

It’s an unusual approach with some major benefits: since the build volume is much bigger (and in the case of this machine, it’s a massive 330 x 180 x 300mm), you can print much larger objects. They’ve even been able to 3D print the entire 3D model of the Notre Dame Cathedral, which normally is done in multiple segments.

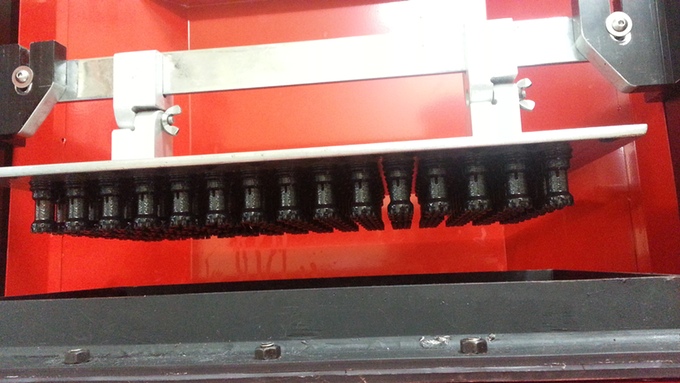

But more importantly, you can print MANY objects in the same print operation. By filling the build volume, you don’t actually take any longer to print, because each layer takes the same amount of time to solidify, regardless of the amount of object present.

Thus, your print throughput is hugely increased. Instead of printing say, eight rings on a B9 Creator resin 3D printer in a small volume, you can on the Morpheus print as many as 256 in about the same time. This is the machine you want if you’re printing lots of items, particularly duplicate items.

You can pre-order a unit now on their Kickstarter page, with delivery set for December 2015. At this time, the pricing is set at USD$3,999 and rising as units are sold.

Since this is a crowdfunding campaign, you must be wary of investment, as some ventures have failed. However, in this case, OWL WORKS has already far surpassed their initial funding target, making production more likely. Even better, the price they’ve set for this machine is sufficiently hefty to ensure they have enough cash flow to actually deliver. In fact, if they sell out, they’ll have several million dollars to work with.

Check them out at the links below.

Via Kickstarter and Morpheus 3D Printer