In 2009 something happened that started a 3D printer boom. That’s going to happen once again.

Why? Because there’s another round of patents set to begin expiring. In 2009 the original patents for plastic extrusion 3D printing technology finally expired, opening up a legal path for companies such as MakerBot, Ultimaker and projects like RepRap to design very inexpensive machines from which much of today’s 3D printing industry emerged.

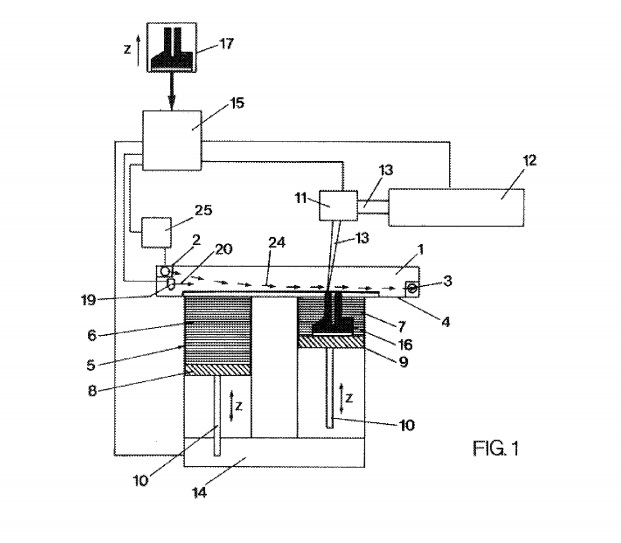

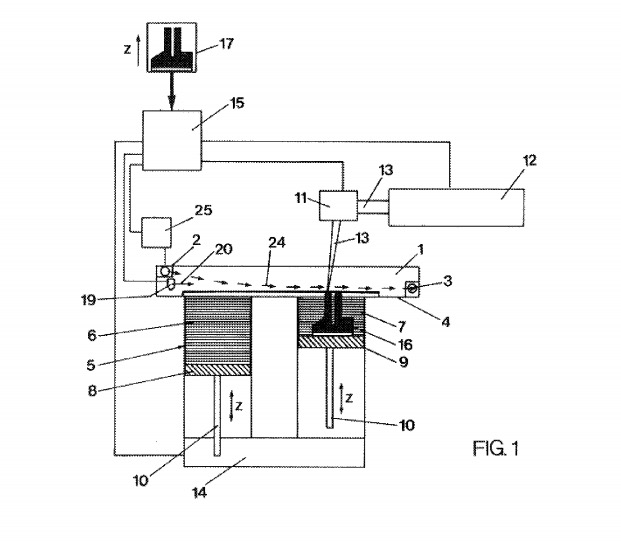

Now there’s another key patent expiring. It’s by the Fraunhofer-Gesellschaft zur Foerderung der Angewandten Forschung E.V., or Fraunhofer Society for the Advancement of Applied Research E.V. and is entitled, “Selective laser sintering at melting temperature”. Here’s the abstract:

A method is disclosed for manufacturing a molded body, in accordance with three-dimensional CAD data of a model of a molded body, by depositing layers of a metallic material in powder form. Several layers of powder are successively deposited one on top of the other, whereby each layer of powder is heated to a specific temperature by means of a focused laser beam applied to a given area corresponding to a selected cross-sectional area of the model of the molded body, before deposition of the next layer. The laser beam is guided over each layer of powder in accordance with the CAD cross-sectional data of the selected cross-sectional area of the model in such a way that each layer of powder is fixed to the layer below it. The method is characterized in that the metallic material in powder form is applied in the form of a metallic powder free of binders and fluxing agents, that it is heated by the laser beam to melting temperature, that the energy of the laser beam is chosen in such a way that the layer of metallic powder is fully molten throughout at the point of impact of said laser beam, that the laser beam is guided across the specified area of powder in several runs in such a way that each run of the laser beam partly overlaps the preceding run, and that a protective gas atmosphere is maintained above the interaction zone of the laser beam and the metallic powder.

Yes, you read that right: this is the patent for 3D metal printing. Or at least the a common process used today by metal 3D printer manufacturers.

With this patent expiring in December, it should become possible for others to develop – hopefully at much lower cost – 3D metal printers, in the same way that companies like MakerBot did with the plastic extrusion process.

However, there are some challenges here.

First, there is the matter of safety: this process requires fine metal powder, and that’s something that can become airborne. Metals are frequently toxic so you don’t want to be breathing them into your lungs. 3D metal printers would have to ensure safety by including a method of securing loose powder.

Another safety concern will be that some metal powders are actually explosive. Remember the now-retired Space Shuttle? Its solid rocket boosters were powered by aluminum oxide. You know, aluminum powder and oxygen, that stuff in the air around you all the time. This all implies that 3D metal printers must somehow remove the oxygen from the presence of the powder, lest something really bad happen.

Finally, melting metal powder requires a great deal of heat, typically provided by a very powerful laser. Those are not inexpensive and require a great deal of input power.

While I strongly believe there will be low-cost 3D metal printers swiftly emerge based on the patent’s expiry, they’re not going to appear in people’s homes due to the reasons above.

But for industry, particularly small manufacturers who cannot afford the large commercial metal 3D printers, this could be a big deal.

Via USPTO