There are many new 3D metal printers on the market, but most of them produce objects requiring significant post-processing. But not Matsuura’s.

Japan-based Matsuura is one of many new entrants into the field of metal 3D printing. The 500-person company sells several models of a hybrid laser sintering and CNC milling device called the Lumex Avance.

Here’s the concept: use the familiar powder / laser sintering process to 3D print a metal object in a manner very similar to multiple other vendors. However – and this is the key part of the process – stop 3D printing after each 0.5mm segment of layers and engage an onboard CNC mill to smooth the last 0.5mm printed. I should note that each layer is 0.05mm, so ten layers are printed before milling occurs.

When the print completes, you will find a metal object that has been completely smoothed by the near-continuous milling process. There is far less post processing required.

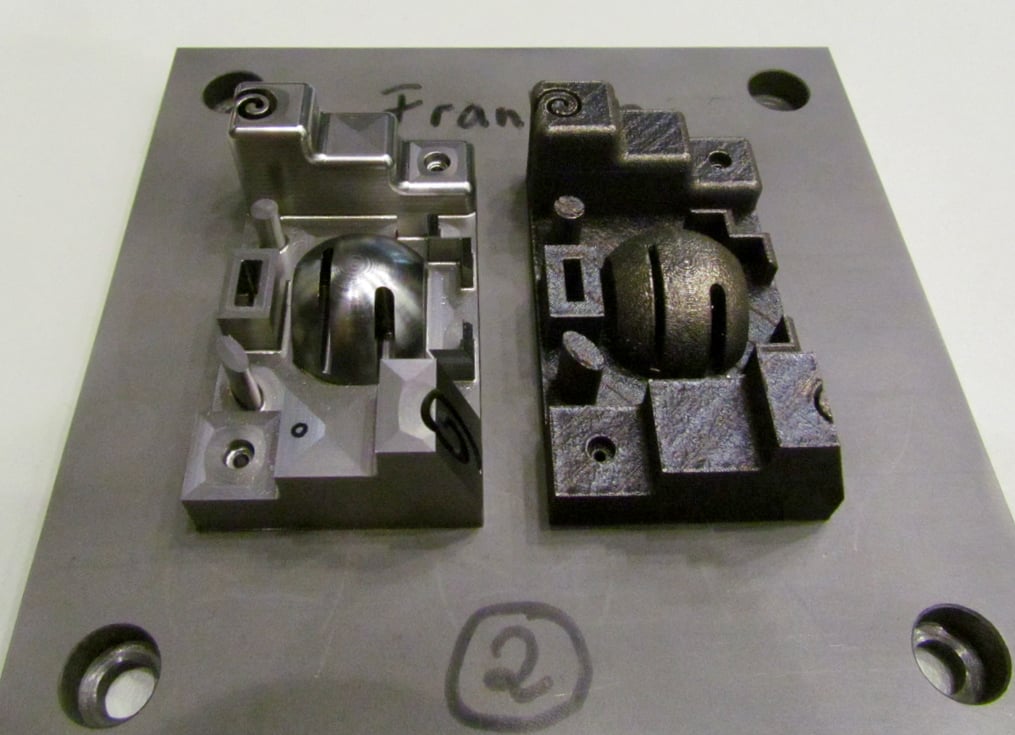

Here you can see an example of how the process works. On the right is a metal object printed without in-process milling, while on the left is the same metal object that’s had the in-process milling occur. See the difference?

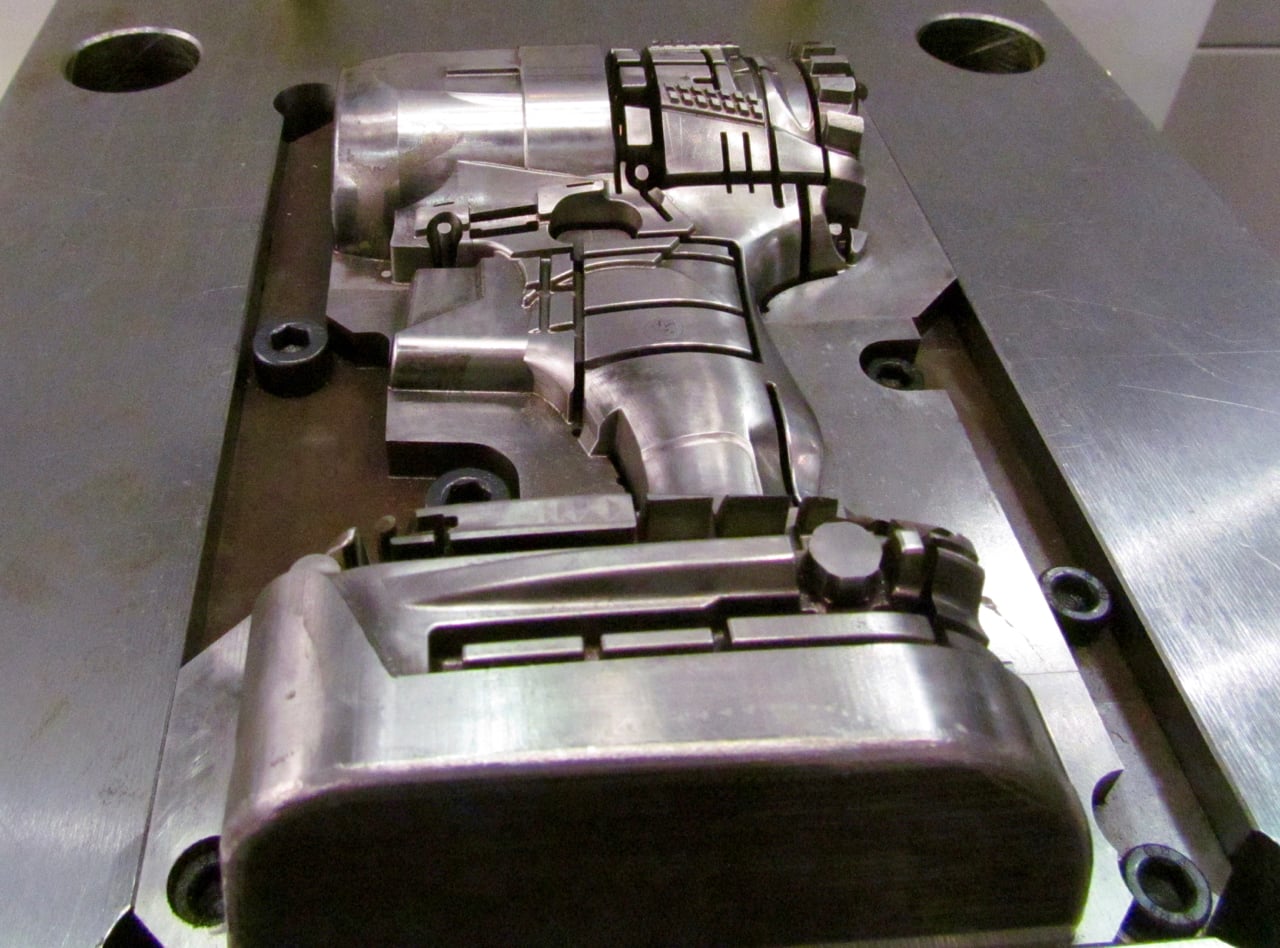

Here you can see a very elaborate metal print, with smooth surfaces, crisp edges and plenty of detail. That is simply not possible on other 3D metal printers without considerable post processing.

A key advantage of this approach is that interior features can be successfully milled. If you were to print the entire object and mill it afterwards, you might not be able to gain access to all portions of the object due to geometric restrictions. There are no such constraints in Matsuura’s approach.

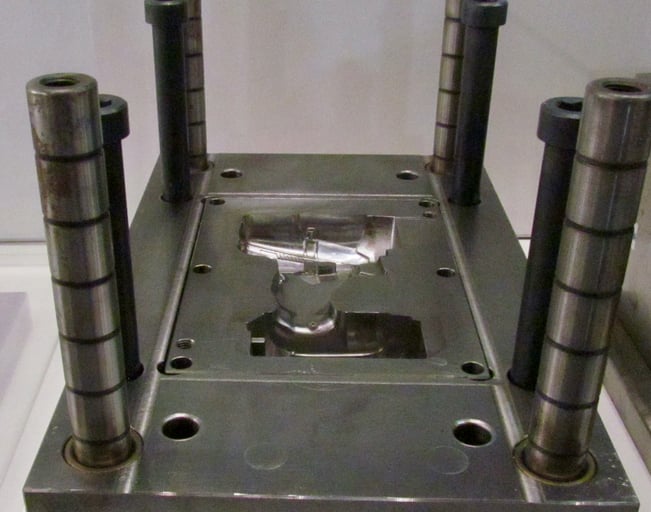

This means Matsuura’s process is ideal for producing metal molds for injection molding processes. They should be more or less ready to go as soon as they emerge from the Lumex 3D metal printer.

Currently they support seven different metal materials, but you’re permitted to use other metal powders in the machine.

Matsuura has been selling machines since 2003 in Japan, and since 2011 in Europe, 2014 in the USA, with 80 units in Japan and around 60 elsewhere. However, note that these systems are not inexpensive: the small system (build volume 250 x 250 x 185mm) is priced at around USD$750K, and the larger machine almost double.

Matsuura has created a machine that could have a significant advantage over several other 3D metal printers with their technology.

Via Lumex-Matsuura