With all the competition in professional desktop 3D printers these days, it’s hard to stand out. But Loop3D has found a way.

The Turkish manufacturer has produced an apparently “continuous” professional 3D printer. One that can run, in theory, endlessly.

There are two challenges in running a 3D printer continuously. One is to keep loading filament so it doesn’t run out, and the other is to clean off the print bed after each run. The former has been solved by the use of dual material bays in some systems, but the latter is something almost no companies have attempted. Thus it’s typically done entirely with manual labor.

But then Loop3D has a new system that seems to do this automatically, and it’s an ingenious solution.

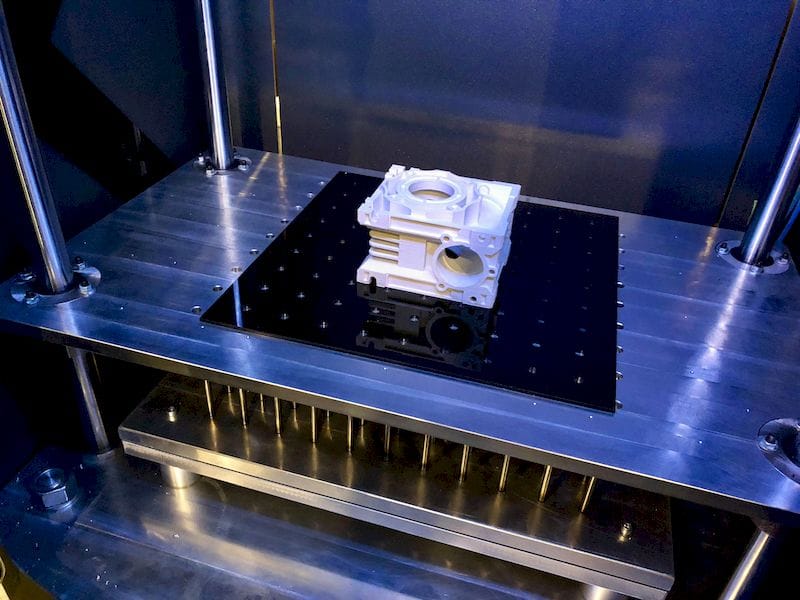

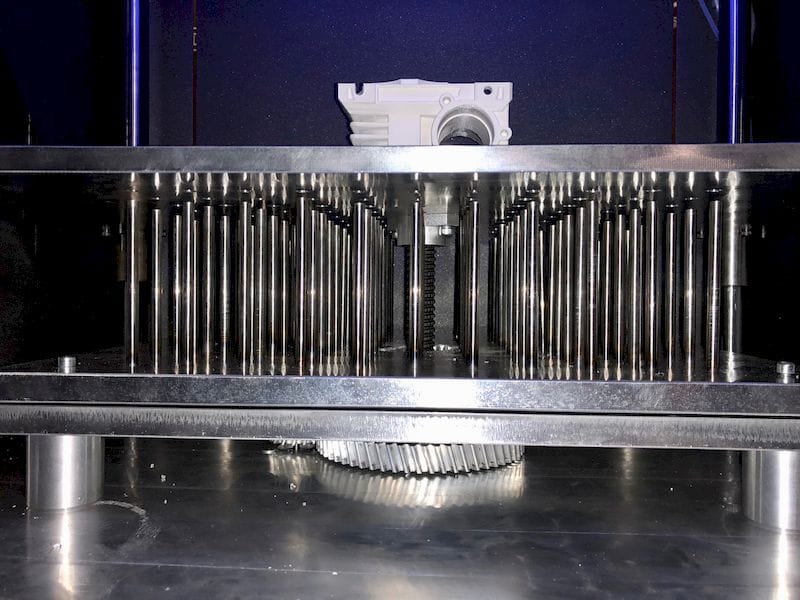

Here’s how it works: the print takes place in the normal manner on what appears to be a typical print bed. Once completed, the bed is revealed to contain a 9 x 9 array of strong metal pins. These pins are are extended through the bed, pushing the print off the print surface. The prints are caught in a basket at the front.

I’ve not seen this approach to automated build plate management previously, but it seems like something that could work well.

But I had one question, after seeing the rather large distance between the pins. What if, I asked, the print was small and laid between the pins?

The answer should have been obvious to me: There is a minimum raft size to ensure the print is encountered by the pins.

The other aspect of continuous 3D printing, supply of materials, is handled in this case by the ability to install filament spools up to 5kg, which are quite large. They should last a week or so in normal printing.

Aside from the continuous aspects, the Loop3D machine appears very competent. It includes well made CNC’d metal components for rigidity and vibration reduction, single or dual extruders and many more features you’d expect to find on a professional desktop 3D printer. Although the unit we saw was a prototype, it was quite attractive visually.

The Loop3D machine is now available for pre-order. Loop3D sells a standard model without the continuous features for €15,000 (USD$17,650) and one that does include the interesting continuous features for €20,000 (USD$23,500).

Via Loop 3D Printer