While there are many prints emerging from 3D printers, there is usually insufficient maintenance being performed on machines.

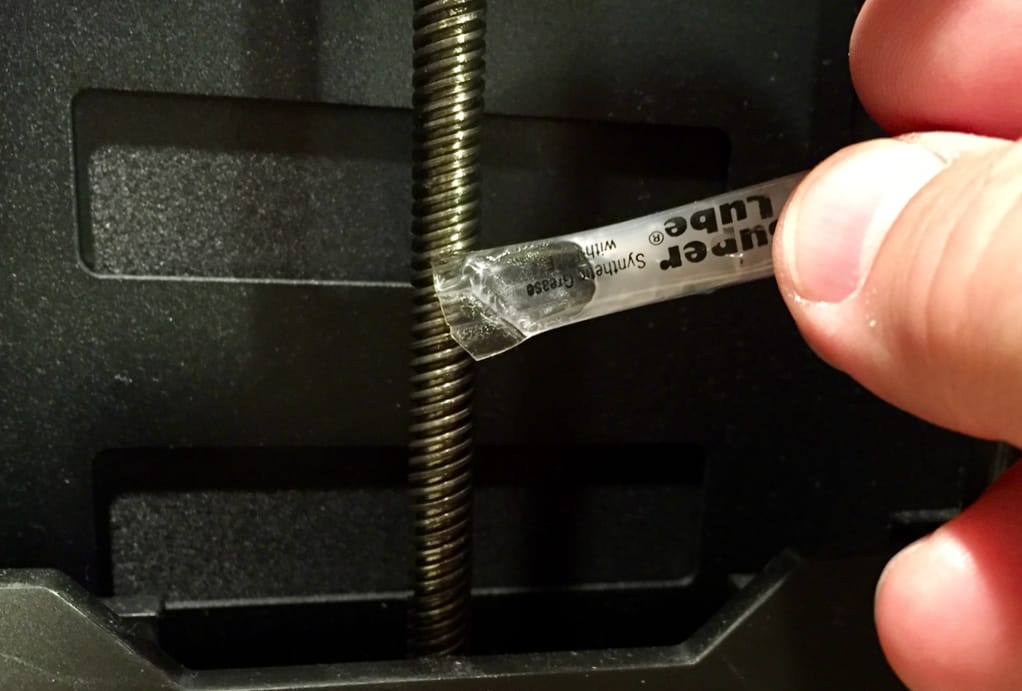

3D printers are highly mechanical devices, and as such they deserve some care and attention. Each manufacturer provides a recommendation for maintenance to ensure the machine continues to work in good order. These instructions typically involve cleaning out debris that can corrupt the motion systems, or lubrication of moving surfaces in contact with each other.

Maintenance is usually a straightforward affair, taking only a few moments and requiring inexpensive tools and supplies. The benefit of doing so is that your 3D printer will more then likely operate correctly for a longer period – and you may even obtain higher quality prints.

But there’s a problem.

Very often 3D printer operators don’t perform the maintenance on schedule, or even doing it at all.

How often? A report from EOS recently indicated they believe it’s enormous:

An enormous 70% of an AM machine’s downtime is due to a lack of necessary, preventative maintenance or the use of unqualified materials.

That’s for their machines, which are large-scale plastic and metal industrial models, often found in professional workshops staffed by experienced operators, who typically understand the value and importance of performing maintenance. The situation in desktop 3D printing is likely far worse.

Due to their popularity among certain segments of the public, desktop 3D printers are often found in locations with operators unfamiliar with the idea of regular machine maintenance. Sometimes the philosophy is “use it until it breaks”.

And that’s often what happens. It’s my suspicion there are countless numbers of “dead” desktop 3D printers located in homes and offices, simply because they require a bit of maintenance that is perceived to be beyond the capabilities of the operator.

It didn’t help that early desktop 3D printers were temperamental and broke frequently, again often because regular maintenance was not performed.

There’s little desktop 3D printer manufacturers can do aside from making their equipment maintenance free, or at least drastically simplifying the maintenance procedures.

For industrial equipment, it’s another story. Most major manufacturers offer annual service programs, in which a specially trained technician drops by to perform required maintenance as per the manufacturer’s schedule. Typically these maintenance programs cost approximately 10-25% of the original list price of the equipment.

That price level could be financially infeasible for some organizations, and in those cases they sometimes go “off maintenance”, and avoid the cost entirely.

If that’s the case, then they have to perform the maintenance themselves. In some cases this is possible, if they have the knowledge, skills and tools to do the work. In other cases it’s not really practical due to the complexity of the machine or if the manufacturer physically locks out others from doing maintenance.

Machine failures are usually fixed at no charge if the machine is “on maintenance” programs, but those “off maintenance” will pay for time and materials (and sometimes travel costs as well) to have a technician make repairs. That can be considerably expensive, but may be the only option for some operators believing their equipment may not fail very often.

These are the situations that cause machine downtime that EOS referenced: machines not being maintained properly (that and using bad materials).

The moral of the story here is that machines should be operated as intended by the designer, if you hope to enjoy reliable, quality 3D printing. And “operation” includes performing maintenance.