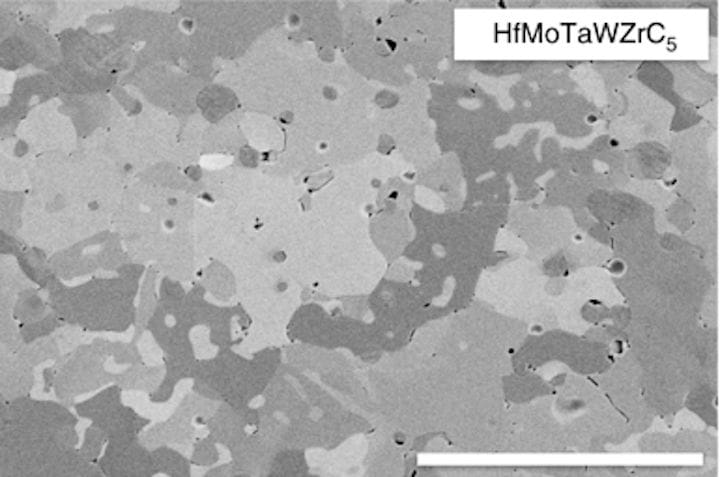

![Electron micrograph of multi-phase HfMoTaWZrC5 specimens [Source: Nature]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a16a5518f.jpg)

I’m reading a scientific paper describing research on new high-entropy, high-hardness metal carbides and wondering how they could be used in 3D printing.

In a paper published in Nature, researchers at Duke University and UC San Diego have been working to develop new kinds of carbides that have much higher heat tolerance, and are substantially higher than currently known carbides, which are already the hardest materials available.

Carbides are a combination of carbon and a metal, and this combination provides not only additional strength, but also resistance to heat. Carbides are typically used in industry where high heat exposure occurs, or where hardness matters, such as in cutting tools.

The researchers combined several common materials in a disordered manner to develop nine different sample materials. These all exhibited unusually powerful engineering properties.

The most interesting aspect of their research is that the materials used are actually relatively common and are available at low cost, suggesting that such high-temperature, high-hardness materials could become widely used in the future.

Carbides are also used in 3D printing: certain advanced nozzles are made from tungsten carbide. These nozzles are the hardest you can buy, with the exception of sapphire nozzles, which are expensive.

Tungsten carbide nozzles are used because they are able to resist the abrasive quality of composite filaments that might be filled with hard metal particles or carbon fibers. These composite filaments typically wear out common brass nozzles in short order.

But could there be even better materials for future high-temperature, high-hardness nozzles?

It seems possible after looking at this research. While the melting point of tungsten carbide is a whopping 2870C, the research paper mentions maximum melting points of some tested materials at 4232K (3960C). That’s a very substantial increase!

Similarly, some of their samples exhibited hardness of 32GPa (giga pascals). That is substantially higher than common metals.

I’m wondering if it would even be possible to develop a metal filament extruder with such materials. However, metals rapidly transition from solid to liquid, making it likely quite challenging.

Via Nature and Space Daily

A research thesis details the incredibly complex world of volumetric 3D printing. We review the highlights.