I’m reading a research paper that proposes a machine-learning approach to stopping the evils of 3D printed weapons.

The paper, produced by researchers at Syracuse University and the University at Buffalo, envisions a kind of “photocopier-like” solution:

It is an urgent challenge to prevent the illegal weapon production in real time manner. The intuitive idea is to make the 3D printer aware of the identity of a printed object so that production can be administrated and the illegal weapon will not be manufactured.

The idea is to equip each and every 3D printer with a database, which they have amusing named “C3PO”. The database would contain tens of thousands of images of various prohibited items from many angles. Thus by using image recognition techniques, the 3D printer could theoretically attempt to identify a prohibited 3D model and stop the print. And, perhaps, report the operator to the relevant authorities, I suppose.

I have no doubt this could technically work, at least at the recognition stage. Those particular 3D models, or those close to them, could probably be detected – if nothing changes. But then I cannot imagine how the rest of this system would possibly work.

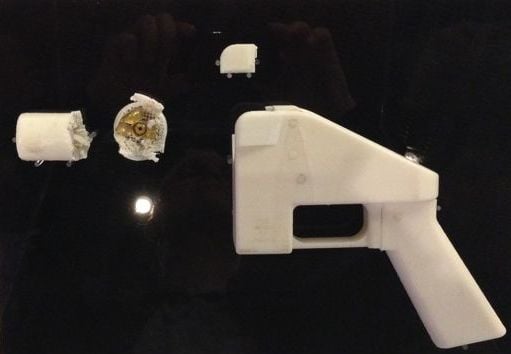

The problem is that things change. If a 3D model of a gun, say, would not be printed, then chop it in half and try again, assembling the pieces later. Oh, that’s detected too? Chop it again. And again. Or a different way.

You could eventually baffle the detector and produce parts for your weapon. Therefore, the detector would then have to become much more sophisticated and detect any conceivable sub-component of weapons. That’s when things really break down, as there could be massive overlap between prohibited and normal components. I can’t imagine a world where you can’t print normal components on your device.

What if it is prohibited only when you print all the weapon components? Would you have to track the sequence of prints, perhaps, in order to somehow determine whether the list of parts being created when combined, would make a weapon? That’s easy to overcome: just print on different printers.

Then the solution would be to track ALL printers and see try to find threads of weaponable component manufacture between machines.

This is clearly ridiculous and impractical to implement.

And I haven’t even gotten to the part where you define “weapon”, which is literally anything. A butter knife is a weapon – we know this because they are prohibited from being taken aboard a commercial aircraft. Should we ban 3D printing of knives? Or anything sharp? Or sharpish? People have been killed by attacks with plain construction bricks. Maybe ban any kind of block shape, too.

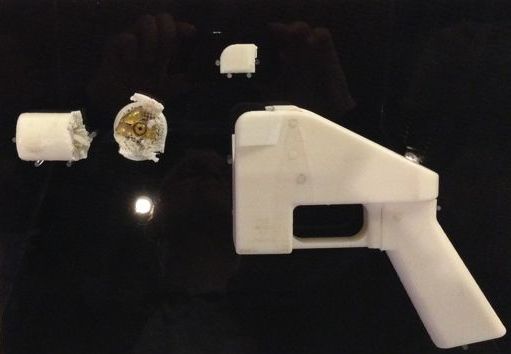

Back to the statement, “It is an urgent challenge to prevent the illegal weapon production.” This is entirely untrue as it relates to 3D printing. No one is producing quantities of 3D printed weapons, because it does not make sense to do so.

Such weapons are of terrible quality and performance, if they work at all. They are also expensive when compared to producing weapons in other conventional techniques.

In fact, almost any city over the size of 10,000 people would most likely have a machine shop with CNC metalworking equipment that could easily produce weapons of vastly superior quality, price, performance and do it a lot faster.

Maybe those operations should be regulated instead?

Cory Doctorow at Boing Boing has many more thoughts about this proposal that you should definitely read.

If 3D printers were regulated in this manner it would definitely pose enormous challenges for the industry and its users. Such research does not lead to helping anyone significantly and simply adds yet another burden of process on top.

Let’s make the world more efficient, please.

Via Arxiv (PDF) and Boing Boing