![Diagram of open sourced component for 3D printer filament production [Source: IC3D]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a622c4361.jpg)

It seems there is another open source filament available for 3D printing, but how exactly is this done?

Aleph Objects announced they’re now carrying a second open source filament for their LulzBot line, a PETg material, from their supplier, IC3D. It’s the second open source filament supplied through LulzBot, the first being an ABS material.

![IC3D’s open source PETg 3D printer filament, being sold by LulzBot [Source: LulzBot]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a62372c2a.jpg)

Open source filament is a rare and confusing concept, so let’s take a look at the concept. Wikipedia defines an open source model as:

“The open-source model is a decentralized software development model that encourages open collaboration. A main principle of open-source software development is peer production, with products such as source code, blueprints, and documentation freely available to the public. The open-source movement in software began as a response to the limitations of proprietary code. The model is used for projects such as in open-source appropriate technology, and open-source drug discovery.”

Note that Wikipedia’s definition talks all about software, albeit with a brief mention of drug discovery applications. That’s because the model works very well for software, which is a digital commodity that is easily shared and improved upon by random contributors.

Physical products in open source mode are far rarer, perhaps because it’s harder to work with than entirely digital products that can be quickly produced on almost any computer. Physical items require physical equipment to produce them, limiting the amount of possible collaboration.

What is it that is being open sourced, exactly? The intent of the open source philosophy is to present to the public the precise method of building the product, be it with source code or other digital artifacts, so that anyone could theoretically produce the product. A software product might require the source code to be compiled into an application, for example, but a physical product would require some mechanisms and physical labor to duplicate the product.

In the case of the open source filament being produced by IC3D, they’re publishing the specifications and process required to replicate the material. Let’s take a look at how they did that.

IC3D’s method of publishing the material is through their GitHub account, a service normally used to distribute open source software using the Git software management protocol. In their “filament-extrusion” section we can see all the files they have released to the public. For the new PETg material, they include:

![IC3D uses one of Eastman Chemical Company’s copolyester resins [Source: IC3D]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a623be3ea.jpg)

Resin Information

This turns out to be Eastman Chemical Company’s standard Eastar Copolyester #6763. This is unexpected, but makes sense. IC3D does not formulate their own resin, but in fact simply uses a pre-made material of excellent quality from Eastman. You might think this disqualifies the PETg as open source, but remember that anyone can buy Eastar Copolyester #6763, just as you might have to buy nuts and bolts for another open source project. It’s just an input component.

Quality Control

The package lists the specifications for Mercury Tech’s Laser Diameter Measurement Ddc-5 Display Controller. This is again not a raw component, but rather a sophisticated item that’s used to measure the quality of the filament as it emerges from your production line. There’s also what appears to be runtime configuration files to operate the laser measurement device.

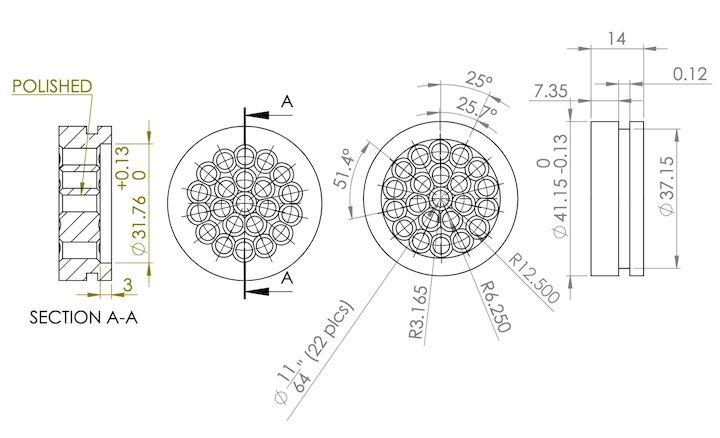

![A “breaker plate” component of a 3D printer filament production line [Source: IC3D]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a6242696e.jpg)

Hardware

The package includes diagrams for producing a number of components used on their extrusion line, including the “breaker plate” shown above. I suspect this is used to begin the extrusion process from a hot pool of material. They also list diagrams for several nozzles used to create filament of different diameters. There are also a large number of files, including .STL files, describing various hardware to link all the key components together. Many of these files are provided in SOLIDWORKS format and thus can be improved upon.

![Blueprint for a 3D printer filament extrusion nozzle [Source: IC3D]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb0a6247562f.jpg)

Respooling

One of the often forgotten requirements of any 3D printer filament production line is a respooler to capture freshly made filament in a smooth manner, rather than having it dumped on the floor like a spaghetti disaster. The GitHub package includes all the files needed to build a respooling device.

![Process overview for 3D printer filament production [Source: IC3D]](https://fabbaloo.com/wp-content/uploads/2020/05/open-source-filament-process_result_img_5eb0a624cea6b.jpg)

Documentation

The package includes a 17-page document that describes the entire process. All the components above are not much use unless you know exactly how to put it all together. Their document explains the entire process, not only assembly, but also operation. If you read this document, you will understand exactly how challenging it is to produce quality 3D printer filament.

And that’s what they provide. It’s definitely not something an individual would consider doing, as it requires not only a bunch of expensive equipment, but also a large workshop in which to operate it. Such production equipment is only worthwhile implementing if you expect to use or sell vast quantities of material.

Is this open source? Absolutely – all required elements are indeed described in full. What’s different from a lot of open source software projects is that the intended target of the project is plastics businesses, not individuals.

If you happen to have an uncontrollable urge to get into the filament production business, you might want to check out this package.

1 comment

Comments are closed.