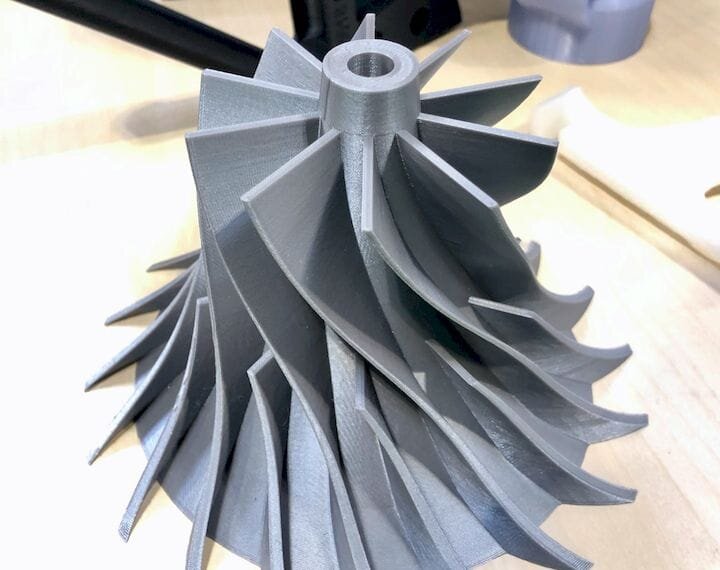

![A high quality 3D print made on the TRILAB DeltiQ 2 [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08e6c30400.jpg) A high quality 3D print made on the TRILAB DeltiQ 2 [Source: Fabbaloo]

A high quality 3D print made on the TRILAB DeltiQ 2 [Source: Fabbaloo]

I had a close look at a very unusual delta-style 3D printer: the DeltiQ 2 from TRILAB.

The Czech company has been around for about three years, and has released a rather interesting professional 3D printer.

Their origin story is similar to what we’ve heard from many other small 3D printer startups: using existing 3D printers proved inadequate, so they decided to make their own, superior machine.

DeltiQ 2 3D Printer

The Open Materials and Open Software DeltiQ 2 is able to produce prints of very high quality for a filament based device, and with a rather large size as well. The device offers a build volume of 250mm diameter by 300mm tall, and there’s a “plus” version with a 500mm height as well.

Here you can see a large 3D print of a branching conduit that displays the high quality of prints from this device.

![A large high-quality 3D print made on the TRILAB DeltiQ 2 [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08e6c86e42.jpg) A large high-quality 3D print made on the TRILAB DeltiQ 2 [Source: Fabbaloo]

A large high-quality 3D print made on the TRILAB DeltiQ 2 [Source: Fabbaloo]

The hot end on the machine is the familiar E3D-Online V6 all-metal unit that seems to becoming an industry standard. But the big difference in this machine is its extrusion system.

Here we see a sample 3D print of flexible material made on the DeltiQ 2. Note the very high quality of the print, and its decent size.

DeltiQ 2 Nimble Extruder

But wait, you ask, “how can you 3D print flexible materials on a delta 3D printer?”

This is indeed a very good question. The reason virtually all delta-style machines have challenges with flexible material is that delta machines typically use Bowden-style extruders. These are mechanisms that push a filament through a long tube towards the hot end. The design allows for a far lighter print head that can more easily be moved and shifted in velocity, leading to higher print quality. Delta machines leverage the lighter tool head in their motion systems.

The problem is that you can’t easily push flexible filament. It’s like trying to push wet spaghetti through a straw. Try it sometime, you’ll have some fun!

As a result, systems with Bowden extruders have little to no ability to 3D print flexible filament, unless the filament is relatively stiff and is printed at extremely slow speeds. Meanwhile, direct extruders allow for easier flexible printing by dramatically shortening the ‘push length” to near zero.

![The TRILAB DeltiQ 2 includes a (red) drive cable to push power to the direct extruder[Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08e6cc98fb.jpg) The TRILAB DeltiQ 2 includes a (red) drive cable to push power to the direct extruder[Source: Fabbaloo]

The TRILAB DeltiQ 2 includes a (red) drive cable to push power to the direct extruder[Source: Fabbaloo]

How can the DelitQ 2 3D printer deal with flexible material?

It’s because it uses a curious extrusion system called the “Nimble” from Zesty. We covered this device earlier, but in short it uses a rotating stiff metal cable that transfers power from the externally located motor to a gear system located near the hot end. Thus you have the low-weight benefit of the Bowden style, but a close drive benefit of the direct style.

![The TRILAB DeltiQ 2 uses a Zesty Nimble extrusion system [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08e6e02091.jpg) The TRILAB DeltiQ 2 uses a Zesty Nimble extrusion system [Source: Fabbaloo]

The TRILAB DeltiQ 2 uses a Zesty Nimble extrusion system [Source: Fabbaloo]

This is how the DelitQ can 3D print flexible material so well.

DeltiQ 2 Features

The DeltiQ 2 has another interesting feature, a removable touchscreen control panel. This is essentially a smartphone device that is programmed to provide all manner of statistics and control over the 3D printer.

![Removable magnetic print plate for the TRILAB DeltiQ 2 [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08e6e4e984.jpg) Removable magnetic print plate for the TRILAB DeltiQ 2 [Source: Fabbaloo]

Removable magnetic print plate for the TRILAB DeltiQ 2 [Source: Fabbaloo]

The print surface is heated, and it’s actually a huge 5mm thick aluminum plate. On this are placed magnetic sheets with appropriate surfaces for various materials, such as PEI for PLA and ABS printing.

The standard DeltiQ 2 hot end is capable of hitting 300C, but with an optional additional sensor, it can reach 350C, allowing 3D printing of many engineering materials, including flexible. TRILAB says these materials are possible: “PLA, PETG/CPE, ABS/ASA, PETG-CF, PC, PP, PVA, BVOH, PACF, PAGF”.

The company also offers an unusual “QuadPrint” edition that is a four-way mixing hot end, allowing for, with appropriate software control, printing with four materials simultaneously. This could also include use of soluble support for the ability to 3D print highly complex geometries.

TRILAB DeltiQ 2 Pricing

The TRILAB DeltiQ 2 is a very interesting 3D printer, priced at €2,600 (US$) for the standard edition and €3,400 (US$) for the larger sized plus version.

Via TRILAB