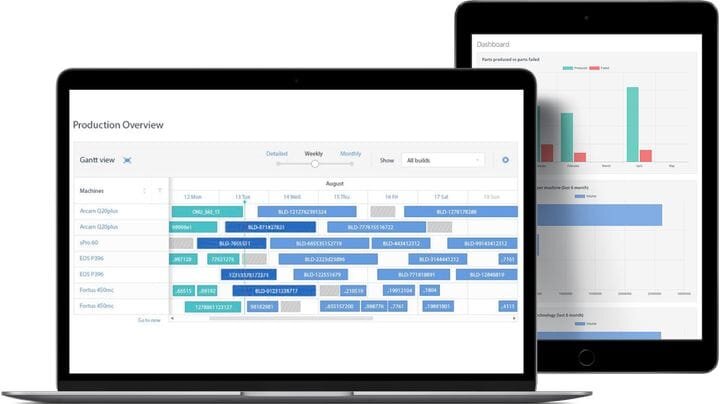

![3D print workflow management [Source: AMFG]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08d0c88efd.jpg)

AMFG announced a partnership with EOS to simplify manufacturing workflows.

EOS is, of course, the well-known manufacturer of industrial 3D printers that can produce production parts in both metal and thermoplastics. But you may not have heard of AMFG.

AMFG Background

They are a London-based company offering a highly sophisticated Manufacturing Execution System (MES). Manufacturing is all about efficient and consistency, and that cannot be achieved in today’s competitive markets without the aid of software tools like MES products.

AMFG’s system provides an end-to-end lifecycle for all the steps required in several typical manufacturing scenarios. For example, their “End-Part Production” solution involves:

-

Order management and outsourcing

-

Automated file analysis and repair

-

Production planning and scheduling

-

Part catalog

-

Post-processing and QA

-

Machine analytics

They provide similar, but customized workflows for Spare Parts Production, Service Bureaus and Rapid Prototyping. As you can see, it would certainly be quite valuable for a manufacturer to make use of such a system to coordinate activities and track all events, particularly as the volume of production grows. AMFG’s mantra seems to be: “Repeatable, Traceable, Automated”.

3D Printer Manufacturing Integration

![Scheduling production 3D print jobs [Source: AMFG]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08d0cce277.jpg)

This gets at something that’s been bothering me for many years: integration of 3D printers into actual manufacturing operations. While many of us examine the 3D printers themselves, inspecting their specifications and costs, we often ignore the challenges of actually using them for true manufacturing.

Almost all current 3D printers are essentially standalone devices that do not fit within the highly optimized manufacturing processes found worldwide in leading plants. These standalone machines, (or, as one pundit told me, “children’s easy bake ovens”), can only be used in an awkward manner as operators must step out of their normal workflow to use them.

Thus I am quite interested in anything that can bring these two worlds together. And that seems to be the goal of the announcement from AMFG. They explain:

“The lack of connectivity across the additive manufacturing workflow remains one of the biggest barriers to adoption. Through their partnership, EOS and AMFG aim to remove this barrier and establish a fully connected and automated additive manufacturing workflow.

Customers of EOS machines will be able to manage their entire additive manufacturing operations with AMFG’s Manufacturing Execution System (MES), whilst simultaneously connecting directly with their machines through the software platform.”

And:

“Through AMFG’s MES software, EOS customers can also prepare build jobs and set important parameters like part orientation. Builds can then be sliced and the data sent directly to an EOS 3D printing system. The ability to monitor and receive machine data in real time is also in the works.”

This integration is only a first step, but will no doubt save significant effort by operators. Any additional efficiency is always welcome!