Charles R. Goulding and Preeti Sulibhavi consider Henkel’s participation in the 3D printing industry and potential preparations for another pandemic-driven lockdown scenario.

Headquartered in Dusseldorf, Germany, publicly-traded Henkel has sales exceeding $6 billion and employs over 50,000 people. Over 25 percent of Henkel’s employees are in the U.S.

On October 14th, 2020, after reporting strong recent financial results, Henkel CEO Carsten Knobel warned against a second wave of coronavirus lockdowns. With COVID-19 case counts increasing in Germany, Knobel’s foreboding lays out a challenge for authorities contemplating further lockdowns.

Henkel 3D Printing

Henkel has three business units, namely adhesives, laundry/home care, and beauty. Through its adhesive Loctite business unit, Henkel has made great progress with 3D printing innovation. For instance, Shapeways, a Loctite partner that brings customers 3D printed parts on-demand, provides instant quotes on custom parts that are additively manufactured.

This week, Henkel announced that it expanded its relationship with Carbon to further develop the industrial 3D printing market. The Loctite-branded formulations will now be validated for use with Carbon’s additive manufacturing process. This agreement has created opportunities for industrial customers of Henkel’s patented single-component technologies for use with the Carbon Digital Light Synthesis (DLS) 3D printing process. As part of this collaboration, Henkel has launched the new Loctite 3D IND405 Clear material certified for Carbon printers. It is immediately available to Carbon customers.

Henkel is helping the confectionery foods industry provide customers with unique experiences. Companies in the confectionery foods industry are seeking to offer more personalized products to enhance their customers’ experience and to grow their businesses. For instance, companies are looking to create personalized candies for special events. When they do not have the capital available to them to (or otherwise prefer not to) invest in machining molds, they can work with Henkel Loctite Additive Manufacturing Services to determine if 3D printing can accelerate their output and enable product customization as well.

Recreational vehicle sales have been taking off. Particularly with this COVID-19 crisis, 2020 has been one of the most profitable years for the RV industry. THOR Industries, a leading manufacturer of RVs, has been experiencing this trend. The influx of business has driven their profit margins but the demand has put constraints on the industry’s supply chain. A typical RV unit contains between 8,000 and 10,000 parts and supply chain delays can derail business. This is where Loctite additive manufacturing helped THOR Industries achieve scalable solutions utilizing the latest 3D printing materials and technologies and testing it firsthand. This collaboration was the perfect solution to meet the tough criteria for RV quality and safety.

Digital dentistry is not new to the world. However, the partnership between Keystone Industries and Henkel is new and has created more opportunities for the dentistry industry to utilize additive manufacturing solutions.

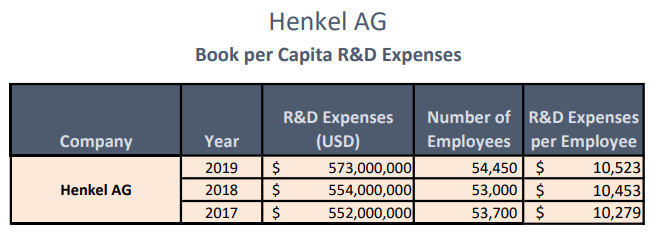

Research and Development Tax Credits are available for the eligible U.S.-based, 3D printing design activities that Henkel engages in.

The Research and Development Tax Credit

Whether it’s used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Enacted in 1981, the now permanent Federal Research and Development (R&D) Tax Credit allows a credit that typically ranges from 4%-7% of eligible spending for new and improved products and processes. Qualified research must meet the following four criteria:

- Must be technological in nature

- Must be a component of the taxpayer’s business

- Must represent R&D in the experimental sense and generally includes all such costs related to the development or improvement of a product or process

- Must eliminate uncertainty through a process of experimentation that considers one or more alternatives

Eligible costs include US employee wages, cost of supplies consumed in the R&D process, cost of pre-production testing, US contract research expenses, and certain costs associated with developing a patent.

On December 18, 2015, President Obama signed the PATH Act, making the R&D Tax Credit permanent. Beginning in 2016, the R&D credit has been used to offset Alternative Minimum Tax (AMT) for companies with revenue below $50MM and, startup businesses can obtain up to $250,000 per year in payroll tax cash rebates.

Conclusion

As a result of its size and financial strength, Henkel is an important participant in the 3D printing industry. Lockdowns are complicated decisions. It is important that industry leaders express their opinions.