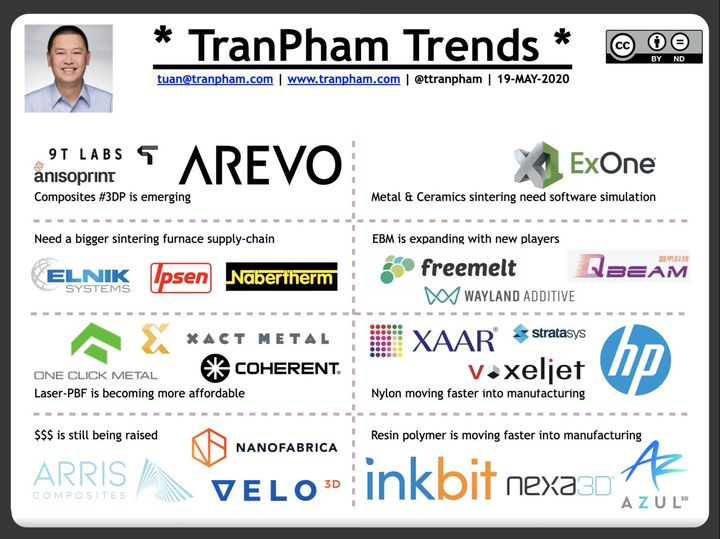

Fabbaloo friend Tuan Tranpham issued a list of 3D printing trends he’s perceived — but are they really true?

Tranpham is one of the more visible people in the 3D print space, having worked for numerous companies and producing various independent research pieces that are frequently thought-provoking. Most recently he’s listed some new industry trends.

Let’s go through his list of eight trends and see what they mean and whether they’re true.

Trend: Composities 3D Printing Is Emerging

Exhibited by: 9T Labs, Anisoprint, AREVO

Analysis: This is quite true.

I’ve spoken with representatives from each of these companies and they are all growing rapidly, with significant interest from buyers and probably investors. The ability to smartly embed continuous carbon fiber into a 3D print can make the parts vastly stronger, opening up entirely new markets for 3D printing. One more company to add here: Markforged. [Note: Tranpham is employed by AREVO, but that company is indeed developing powerful composite technology]

Trend: Need A Bigger Sintering Furnace Supply Chain

Exhibited by: Elnik Systems, Ipsen, Nabertherm

Analysis: I’m not particularly familiar with these companies, but they all supply furnaces for sintering or post-print heat treatments.

However, with the greatly expanding use of metal 3D printing, at least prior to the outbreak of COVID-19, there would have to be a corresponding increase in sintering capabilities. If there are furnace manufacturers adding 3D print capabilities to their products, this certainly makes a great deal of sense. There are plenty more furnace makers that might consider joining the 3D printing party.

Trend: Laser Powder Bed Fusion Is Becoming More Affordable

Exhibited by: Xact Metal, One Click Metal, Coherent

Analysis: This is a trend that’s been happening for the last few years, and it was really inevitable given the sometimes astronomical pricing by the traditional metal 3D printer vendors. In particular, these traditional systems often require a bevy of additional equipment and environmentally controlled workshops in order to successfully produce parts.

These expensive options open the possibility for ingenious lower-cost approaches to enter the market, making it possible for these companies to exist and thrive. One more company to add here might be Desktop Metal.

Trend: $$$ Is Still Being Raised

Exhibited by: Arris Composites, Nanofabrica, VELO3D

Analysis: All of the above companies have indeed recently received significant investments, and that’s something that’s happening for decades.

I think Tranpham is saying here that in spite of the crisis, there are still investments taking place. I agree with this: if a venture is profitable, then it should attract investment, regardless of what else is going on. I expect to see more investments take place during the remainder of the year, but perhaps not the nine-digit blockbuster deals we’ve seen in previous years.

Trend: Metal & Ceramics Sintering Need Software Simulation

Exhibited by: ExOne

Analysis: Indeed ExOne announced a deal with ANSYS to develop said simulations, and the functionality is no doubt needed.

However, is it really a trend? I would hold off on that until I see a few others launch similar projects.

Trend: EBM Is Expanding With New Players

Exhibited by: Freemelt, Wayland Additive, QBeam

Analysis: For many years ARCAM was the only electron-beam alternative for metal 3D printing, but now that’s changed. We wrote on Wayland Additive last week, exploring their “neutralized” method of electron beam 3D printing.

While the electron beam process is definitely a minority in the world of metal 3D printing, there’s nothing wrong with it, and it has particular advantages in certain applications. It should not be a surprise to see more players in that space, but what is a surprise is why it took so long.

Trend: Nylon Moving Faster Into Manufacturing

Exhibited by: Xaar, Stratasys, voxeljet, HP

Analysis: This is definitely true, and perhaps is a side effect of a general increase in interest in 3D printing for manufacturing.

While aerospace “discovered” 3D printing some time ago, the same effect is now slowly happening to manufacturers in a variety of industries. I expect this trend to continue for several years.

Trend: Resin Polymer Is Moving Faster Into Manufacturing

Exhibited by: inkbit, nexa3D, AZUL

Analysis: While possibly a duplicate of the previous trend, I think there could be some deeper truth here when you look at what’s happened during COVID-19.

Several resin 3D printer manufacturers, notably Formlabs and Photocentric, stepped up and demonstrated the ability for their equipment to rapidly produce high volumes of emergency parts. Formlabs, for example, was able to suddenly produce 1M test swabs per week. This rapid capability was surely noticed by industry and could add to this trend in the future.

Are these trends true? Of course they are: Tuan said so!

Via LinkedIn