3D printing has really stepped up to the plate in pandemic response — but what happens with those designs post-pandemic?

As the novel coronavirus spread around the globe and COVID-19 became a pandemic affecting the world, the 3D printing industry answered the call to duty. Quickly iterated and approved designs were 3D printed for use in emergency-use applications in ventilators as well as for lower-stakes (but still critical) use such as creating face shields.

3D printing operations refocused their work, gearing up all their brainpower and equipment to dedicated COVID-19 response production. Thousands of face shields and other types of personal protective equipment (PPE) were made and distributed to frontline workers who still had to interact with contagious, or potentially contagious, individuals day in and day out.

One of the most popular designs in face shield response emerged early on from Prusa Research.

Prusa Pandemic Response

The Czech company showed itself a real leader in pandemic response among the 3D printing industry.

In addition to in-house hand sanitizer manufacture, strict mandates to protect employees’ health, and other precautions and actionable responses, Prusa’s biggest contribution was perhaps the freely available open source design for a face shield.

The face shield has been downloaded countless times, Josef Prusa told me when we spoke in March, having had to disable the counter because it was slowing site speeds. When they turned it off, the design had already been downloaded more than 101,000 times — and our conversation was just eight days after its release.

The Prusa team took a prototype of the face shield to the Czech Ministry of Health for approval, and it moved quickly then into field testing and full approval. Prusa Research 3D printed 20,000 and donated more than 12,000 of the shields throughout Czechia. Again, that’s all as of our conversation in mid-March.

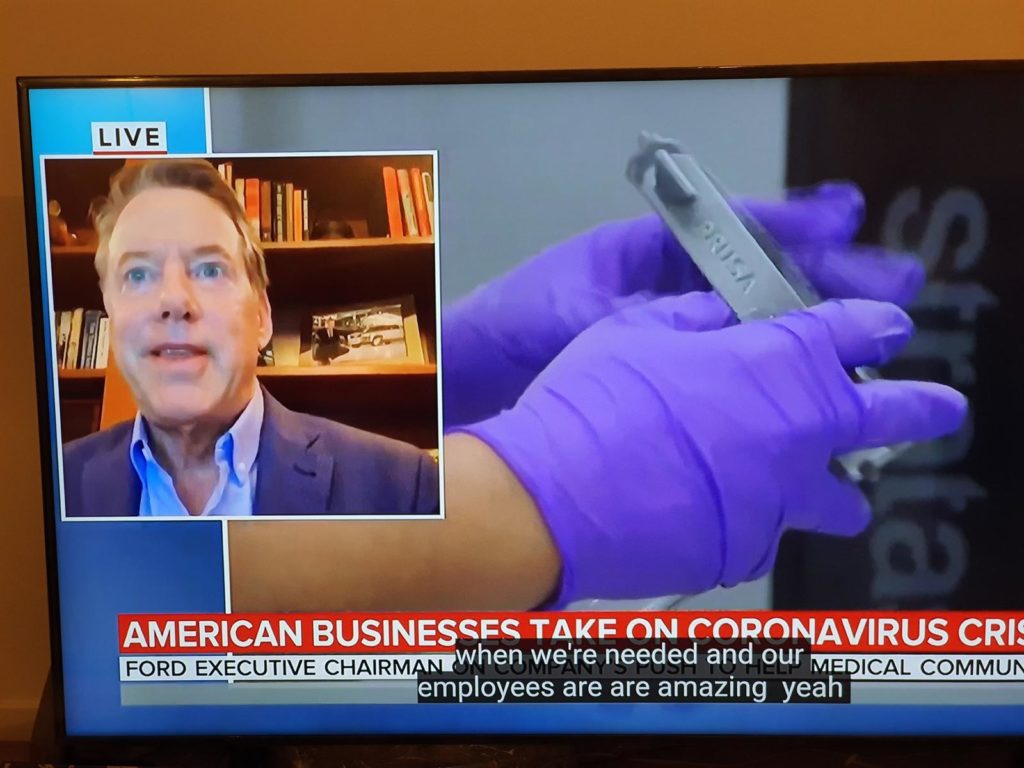

So popular were these particular face shields that they’ve been seen everywhere — including on camera in coverage about Ford Motor Company’s lauded efforts to turn its lines into PPE and other pandemic response manufacturing needs. Ford is well known for 3D printing on its lines, and while it touted face shields as among the PPE it was making, no outward word of credit to Prusa was heard (despite the clearly visible “Prusa” on the side of a face shield shown in a news segment). Josef Prusa shared this screenshot:

3D Printed Face Shields

Of course, Prusa’s is not by a long shot the only face shield design out there. Other popular versions hail from such entities as 3DVerkstan and Budmen Industries.

They’re all pretty similar, naturally, and at heart pretty basic: a (3D printed) headband affixes a (generally laser cut) plastic shield to stay in front of the wearer’s face. The intent is that the shield simply keeps expectorated droplets from reaching the wearer, as COVID-19 is a respiratory disease spread most easily through breathing in the expelled virus from someone carrying it, whether symptomatic or not.

Many of these bigger-name face shield designs have also been vetted and approved as PPE, showing that the design will keep the wearer appropriately shielded. These are available in the NIH COVID-19 3D print repository.

One other thing these designs have in common is that they’re open source, freely printable for whomever can make them to get them into the world. Well, most of them are open source.

Patenting A Face Shield

Some level of controversy has broken out, though, when it comes to crediting and sourcing these designs.

Let’s be very clear: no one has ever suggested that getting PPE designs out into the world isn’t the first priority. Everyone working on designing, making, and distributing PPE is doing so to help a world faced with pandemic.

But as some regions begin to show palpable results in slowing and even stopping the local spread of COVID-19, there’s some breathing room to examine the business aspects of what’s been happening. It’s here that we’ve been able to have conversations about the future of the 3D printing industry, which has seen a raised profile through all this among the general public, for instance.

On Friday, Josef Prusa flagged for our attention a new face shield design on the block, emerging from the University of Tennessee, Knoxville (UTK), tweeting:

“@UTKnoxville can you please explain how you let people patent open source designs shared for free for helping in pandemic with just little style changes? Shame on you!”

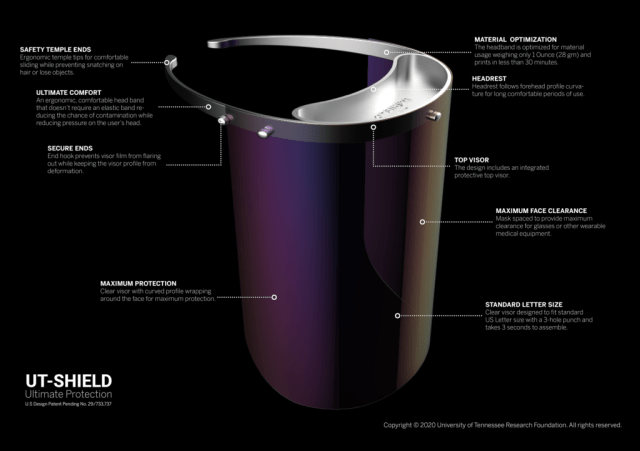

I looked into the design (as did many other Twitter users), created by UTK Assistant Professor of Architecture Maged Guerguis. UTK describes the face shield:

“The patent-pending design benefits the medical professional in many ways. The headband follows the curvature of the forehead to allow for comfort over a long period of time, and the clear visor is spaced with maximum clearance from the face to allow for glasses or other medical equipment to be worn comfortably. The design also includes ergonomic end tips to prevent snagging on objects.”

They’ve even made a swanky video showcasing it:

But it was one phrase here that’s caught attention: “patent-pending.” The UTK article notes that the face shield has been “designated US patent pending (No. 29/733,737).”

Twitter users in the 3D printing community were unimpressed with this move.

I reached out to the university, emailing Professor Guerguis and several contacts listed alongside UTK information releases. They responded this weekend:

“Regarding your question about the patent:

As part of our ongoing initiatives to share knowledge and resources during the pandemic, the university plans to offer a non-exclusive royalty free license for use of the design for COVID-19 efforts. The design includes innovative features and was made from scratch. The university’s research foundation filed the patent to protect the researcher’s intellectual property for potential applications of the design beyond the pandemic response.”

This per Owen Driskill, Assistant Director, News and Information at UTK’s Office of Communications and Marketing.

Face Shield Use Beyond Pandemic

I suppose this does raise a fair point; what becomes of all these designs “beyond the pandemic response” for which they were created?

Designers certainly have a right to their intellectual property.

The UTK design does have some differentiation from existing designs, and doesn’t look — aside from being a headband with a plastic shield attachment — distinctly derivative of others available, so it is original in that sense. It was also made with particular attention to reducing print time and material need, which is a plus for anyone who’s been troubled by the print time of earlier designs available.

The problem right now, though, is a simple one: we’re not yet “beyond the pandemic response.” While many countries’ efforts in fighting the pandemic are proving successful — my local morning radio this morning was discussing New Zealand’s declaration today of being effectively free of the disease with no current known cases — many are still mired under this public health emergency. In the US, we’ve surpassed 110,000 COVID-19 deaths, for example; certainly we’re not past pandemic yet.

IP is a touchy issue at the best of times, and in many cases it’s a good idea to lay the groundwork for safeguards early on to ensure appropriate credit when a design will be patented.

Is it too early for that designation from UTK, though? It does sound as though the design will remain freely available during this pandemic-driven need period, which we can all agree is a good plan.

Still it perhaps isn’t surprising to see that the phrase “patent-pending” is rubbing some people in the 3D printing community the wrong way, especially while we’re still in a world stricken by active pandemic.

Via UTK