Charles R. Goulding examines how Wabtec’s use of binder jetting for spare parts highlights important trends in rail infrastructure spending.

The June 22nd issue of Barron’s has an article covering rail product manufacturers, entitled “4 Industrial Companies to Bet on a Recovery.” Wabtec is modernizing older locomotives converting them from DC to AC power which increases horsepower by 50 percent, which mathematically enables 2 locomotives to do the work of 3 locomotives.

The 2019 merger with GE Transportation made the company a rail powerhouse that can capture digital freight logistics utilizing transponders and satellites. The company is known for predictive analytics capabilities which makes rail more efficient, reduces costs, and improves safety. Anticipated infrastructure spending and re-shoring should benefit the US rail industry.

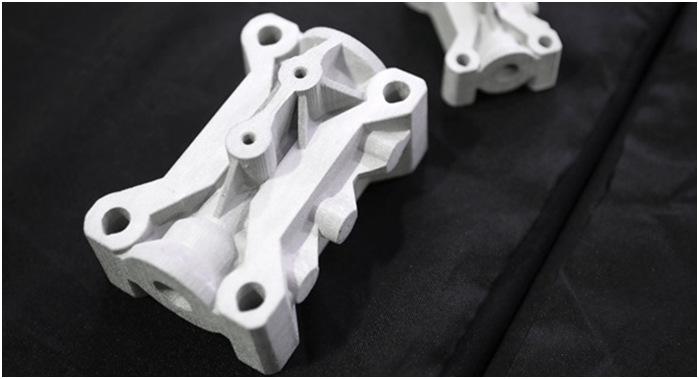

Wabtec provides parts to most major rail transit systems in the world. Its portfolio includes several highly-engineered metal components and systems that it produces in over 100 manufacturing plants. The company has identified that additive manufacturing technologies, or 3D printing, could be used in the production of up to 250 components in its product lines by 2025.

With GE’s H2 Binder Jet Printer the company will be able to create spare parts to order, thereby reducing customers’ inventory requirements while supplying them within very short lead times. The aim is to keep inventory just-in-time (JIT).

Spending on modernizing older locomotives into more efficient modes of transportation can be supplemented by US Federal Research and Development Tax Credits.

The Research and Development Tax Credit

Enacted in 1981, the now permanent Federal Research and Development (R&D) Tax Credit allows a credit that typically ranges from 4%-7% of eligible spending for new and improved products and processes. Qualified research must meet the following four criteria:

- Must be technological in nature

- Must be a component of the taxpayer’s business

- Must represent R&D in the experimental sense and generally includes all such costs related to the development or improvement of a product or process

- Must eliminate uncertainty through a process of experimentation that considers one or more alternatives

Eligible costs include US employee wages, cost of supplies consumed in the R&D process, cost of pre-production testing, US contract research expenses, and certain costs associated with developing a patent.

On December 18, 2015, President Obama signed the PATH Act, making the R&D Tax Credit permanent. Beginning in 2016, the R&D credit can be used to offset Alternative Minimum Tax (AMT) for companies with revenue below $50MM and, startup businesses can obtain up to $250,000 per year in payroll tax cash rebates.

Life on the Tracks

Wabtec has greatly benefitted from GE’s tribal knowledge, including 3D printing and restructuring needs. It is good that this valuable legacy is preserved.