Supermaker Naomi Wu answered our questions about the upcoming Creality CR-30 belt 3D printer.

Shenzhen-based Wu is well-known in the 3D print community for her efforts to promote the maker movement as well as building some interesting designs herself. One of them, the TTGO T-Beam Shock Resistant Enclosure, was our Design of the Week a few months ago.

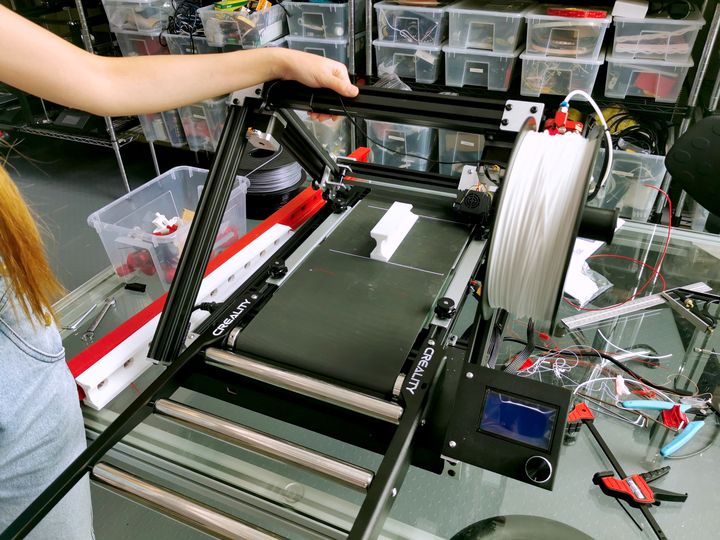

A project she’s working on these days is Creality’s upcoming belt 3D printer, the CR-30, or 3DPrintMill. This unusual 3D printer prints at an angle on a moving conveyor belt to allow for continuous 3D printing or the production of objects larger than the 3D printer itself. In this video Wu introduces the device:

We asked some questions to find out more about the project and what we can expect to see when it is released.

Fabbaloo: Can you relate how this project got started and how you became involved? What’s your relationship with Creality and White Knight / NAK 3D?

Naomi Wu: “I became aware of infinite-Z printers in about 2016 when Bill Steele showed off his designs. I immediately saw the potential but at that point, both making and buying one were beyond my means. In 2018 I arranged for Bill to meet with the Creality founders here in Shenzhen about designing a custom 3D printer for them with an infinite-Z axis. It was a friendly, productive meeting but the Creality bosses still didn’t see the market for a belt printer at that point. Bill was thankfully very gracious about it and we stayed in touch. Eventually, the Creality founders agreed to allocate some in-house resources and engineering time to the project, with me overseeing it. In 2019 Karl Brown, aka. Nax3D made his White Knight and I spoke to him, but since he was selling kits I opted as a courtesy not to use his Open Source design and instead continue to develop an independent design, although drawing on his ideas of course. We stayed in touch, and when I finally had something pretty close to ready for market, Karl agreed to come on as a paid consultant and has really brought it to the next level.

Those of us who’ve been around awhile, the way previous Open Source 3D printer designs were brought to market in China… well aside from everything else it was just disrespectful to the people who created those designs: companies taking credit for ‘inventing’ almost stock Prusa and Replicator clones. Yes, you can copy, but there’s a right way to do that. It’s been bad and it never sat right with me, and you have to bite your tongue when the community complains about it, because they are right. I’ve been waiting for years to prove it wasn’t clever or good business to act this way, that it was short-sighted. So far with the 3DPrintMill that’s been true and I owe a lot to Karl and Bill for letting me show some people here that if you do things the right way, play by the rules, the community will support you.”

Fabbaloo: Is the machine the CR-30 or the 3DPrintMill? Or are those two different things?

Naomi Wu: “The Creality part number is CR-30, the product name is 3DPrintMill. It’s really intended for small scale manufacturing so I wanted a name that evoked that: lumber mill, steel mill etc., while it’s also a play on ‘treadmill’ because of the belt.”

Fabbaloo: I first used a belt-driven 3D printer in 2010 with the MakerBot “Automated Build Platform”. While the device was a bit flaky, the ability to 3D print a continuous stream of objects seemed very powerful. Today I still see skepticism about the belt concept from many people. Why do you think there has been a lack of interest in this concept? What is it that people don’t understand?

Naomi Wu: “Lack of interest is news to me, my inbox is packed with requests for pre-production units. From most of my discussions, it’s always been concerns over the ABP patent that is now owned by Stratasys. The infinite-Z does not violate that, but people are still concerned about such a big player objecting and didn’t want to take the chance.

The interest has been pretty overwhelming, and to be honest, a bit of skepticism is healthy. I’m not trying to sell this to people who don’t need it and convince them they do. There’s not going to be one of those Kickstarter videos with a bearded hipster dude with a MacBook and ukulele music in the background. That’s not who this is aimed at. The people who need the 3DPrintMill know exactly why they need it the minute they see how it works. It’s like a Bridgeport milling machine or high-end gaming computer. People who look at one and are like, ‘what’s that for?’ probably shouldn’t buy it.

This isn’t for small figurines, it’s not a good first printer for kids. I’m really targeting people or businesses who print long objects, like cosplay and prop makers, sign makers, restorers for crown molding and other long decorative elements, but mostly those who need to fabricate 10-1000 objects — small scale manufacturing, Etsy and eBay stores, local machine shops as a cheaper alternative to CNC to offer customers, people printing PPE and emergency supplies — that kind of thing.

It has the potential to be fantastic for education once we can queue up prints, it means little hands can get their part after it drops into a bin, not reaching under hot ends to pry them off heated beds. But the 3DPrintMill is not meant to replace traditional FDM 3D printers and a bit of a reality check there is a good thing. If you’re a teen saving pocket money, for goodness sakes get an Ender-3 as a first printer for $200, not this thing.”

Fabbaloo: The MakerBot ABP’s major flaw was the belt itself, which, after repeated heating would tend to distort, becoming an un-level surface for later prints. How has belt technology changed? How durable can a belt be over the long term? Will it be a consumable item?

Naomi Wu: “I think the initial impression going in was that special belts were needed. I think the reality is a larger belt ecosystem to choose an appropriate belt from was what was needed. When Charles Pax built the ABP, he had, at best whatever McMaster Carr had to work with. And whatever relatively small assortment of conveyor belts they had didn’t work, nor did the paper or Kapton and other materials he tried to make his own belts with. The belts they had warped with the print or fell apart and it was decided that more exotic belts were needed.

The thing is, these problems, curling, stretching, heat resistance, they aren’t actually all that unusual in a manufacturing setting. So here in Shenzhen, we had no problem ordering dozens and dozens of different belts from local suppliers designed with different materials to deal with exactly these issues. So while I’d love to tell you the belt is Creality’s ‘secret sauce’ or some sleazy startup nonsense, it’s really not. There are established, well-tested materials that do exactly what we need really well and do so in an industrial setting for thousands of hours under far more strenuous conditions. How many hours exactly remains to be seen, but far more than I or Karl have managed to put in even with basically 24/7 printing for weeks.”

Fabbaloo: Obviously 3D print job preparation for belt 3D printers must use modified versions of current slicing software, and that’s known to work. But how do you think slicing software will evolve for belt printers? For example, would we want to randomize the location on the belt of a repeating print to avoid belt wear, or automatically create serial numbers to track prints that land in the collection bucket? What other future features do you foresee for belt printer slicing?

Naomi Wu: “Well, BlackBelt3D made a huge contribution with BlackBelt Cura and deserves a lot of credit for that. Bill Steele has a post-processor to convert standard GCODE for infinite Z but it’s nowhere near as polished. Getting software and firmware done in China to an acceptable standard is tough, but I’ve got Creality hiring foreign consultants now like Karl Brown and Scott Lahteine — the Marlin lead developer now. That’s worked out really well for them so I think they will expand that. So I’m confident software improvements will get done, and get done properly, even if we can’t do it in-house. What features get added — that’s going to have to be community feedback.”

Fabbaloo: What has been the most difficult technical challenge in building 3DPrintMill? What advice would you provide to others intending on developing a belt 3D printer?

Naomi Wu: “I think Karl, Nak3D, really solved the biggest problem when he proved there was no one single insurmountable problem standing in the way of low cost, infinite-Z printers. Sure belts are a pain to source — but his steel belt works great. The 3DPrintMill isn’t revolutionary, it’s just iterative. I didn’t try to invent anything completely new — we aren’t that good at that. I did what I knew a Chinese factory and a large team of engineers could do really well: make it cheaper, make it more reliable and mass produce it. The plan is to Open Source the 3DPrintMill, if you want to make a belt printer those design files will be a great place to start and I’m really looking forward to seeing what people come up with.”

Fabbaloo: Complex 3D prints are a lot easier when you can use soluble support material, but that requires multi-material capability. Do you think it would be possible to implement multi-material options on the 3DPrintMill or future versions of the 3D printer? What would be the best approach to do so?

Naomi Wu: “Multiple print heads are definitely the next step. They won’t be a stretch goal, but certainly something for a ‘Pro’ version of the printer after this one has shipped and we have more feedback from users.”

Fabbaloo: While I’m sure the 3DPrintMill will be of interest to hobbyists, what features will appear in the 3DPrintMill and its software to specifically attract small manufacturers? What will make the device attractive to business?

Naomi Wu: “Unattended printing. The old trick with knocking a print off the bed is cute, but it’s time-consuming to set up in the real world because each part shape adheres to the bed a bit differently, it’s why it’s not a standard practice written into the firmware or slicing software. Robot arms with trays work, but the arms cost the same as a year’s salary for two employees. Belt printers — you just put a bin in front of it and the parts pile up. The real key feature we have to get in there though is being able to have one object’s GCODE file on the card, and select at the machine interface how many copies you want. At the moment that’s still done in the slicer and not optimal.”

Fabbaloo: I’m sure you cannot say specifically, but can you provide a hint as to when we might see this amazing device available for purchase?

Naomi Wu: “Shooting for November.”

[UPDATE: The CR-30 is now available on Kickstarter and is selling rapidly. Click here to view.]