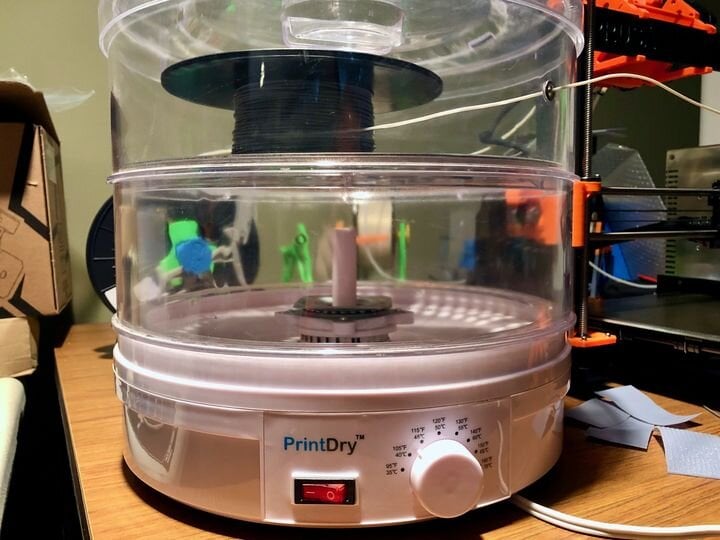

![A typical inexpensive 3D printer filament dryer [Source: Fabbaloo]](https://fabbaloo.com/wp-content/uploads/2020/05/image-asset_img_5eb08b8c058d0.jpg)

I’m beginning to see a pattern in 3D printing progress, and the latest chapter is now unfolding: filament drying.

Increasing 3D Print Quality

From the very beginning the eternal quest of 3D printer operators is to achieve a “perfect” 3D print. That is to say, one that is dimensionally accurate, with near-isotropic bonding between layers and with excellent surface quality. Since the widespread emergence of desktop 3D printers, companies worldwide have taken a number of steps to improve the quality of their device’s output.

Of course, the original patent-holding 3D printer manufacturers had this mostly figured out by then, but it’s been fascinating to observe what’s happened since 2009 when the patents expired and companies began producing inexpensive 3D printers.

I now realize there have been what might be called “waves” of change that wash over the industry. It seems that companies tend to copy each other’s innovations, so long as it’s a legal thing to do. Here’s what I’ve seen over the years.

Waves of 3D Printer Improvements

In the early days the quest for quality began with the machine itself. Often you’d hear new machine specifications that somehow would lead to better quality output. This is still practiced today, but long ago it was almost the only visible move to increase quality by most vendors.

Then we saw an increase in the sophistication of 3D print preparation software. As jobs were sliced, new and complex options were made available in many systems to provide additional benefits in overall quality, strength, or surface texture. This process continues as each release of slicing software is more sophisticated than the last.

Then we saw a maturation of the 3D printer materials. While things started in 2009 with “ABS Welding Wire” obtained from local industrial outlets, companies eventually emerged to develop new materials specifically designed for 3D printing. This step significantly raised the quality of prints, as anyone who’s used quality filament can attest. Again, this continues today, especially with the recent membership of big chemical companies in the 3D printing club.

Filament Storage Increases Print Quality

Today I think there’s another wave starting: filament storage. It’s long been known that exposing filament to the ambient air can corrupt the quality of the filament and consequently anything 3D printed with it. All filaments are affected by this from one degree to another.

ABS, not so much, but PLA can eventually shatter to pieces if abandoned for too long. Nylons and other hygroscopic materials can rapidly absorb atmospheric humidity and become unusable for 3D printing. Many soluble support materials are particularly susceptible to humidity exposure, as are many newly-popular engineering thermoplastics, such as PEEK. In fact, some of the first users of newly minted high temperature machines found they could not successfully 3D print PEEK unless it was properly stored and dried.

Filament Drying Strategies

With all that in mind, there are now multiple options appearing to store 3D print materials securely to maintain their quality before and during 3D printing. Some of these are standalone units, where larger volumes of material can be stored, such as the PolyDry unit we wrote about the other week.

Other units are designed as accessories for a 3D printer, in that they both store the filament and feed it out to the 3D printer in an attempt to minimize exposure to the atmosphere at any stage.

Finally, an increasing number of 3D printer manufacturers are literally building drying chambers directly into their printers. It’s now increasingly common to see a 3D printer with a lower or side module designed to hold a spool or two in dry conditions.

If you were to put these developments together in an equation, it might look something like this:

-

Good quality machine mechanics +

-

Sophisticated software slicing +

-

Purpose-designed material chemistry +

-

Proper material storage

Together, those factors should assure a high probability of 3D print success.

When you think about it in this way, you must wonder about 3D printer configurations that do not include all of the above. Can they be long for the world?

What will the next quality-improving factor be?

Filament drying and overpriced filament dryers are nothing new. A $30 food dehydrator and 3 minutes trimming the stack ring shelves off of the rings is all you really need.

Yes, external dryers have been available for a while, but we’re talking about much more sophisticated units that are increasingly being built-in to the 3D printer, and there are even some that use vacuum drying as well.

Filament drying and overpriced filament dryers are nothing new. A $30 food dehydrator and 3 minutes trimming the stack ring shelves off of the rings is all you really need.

Yes, external dryers have been available for a while, but we’re talking about much more sophisticated units that are increasingly being built-in to the 3D printer, and there are even some that use vacuum drying as well.