This year’s report highlights the industry’s return to pre-pandemic growth as well as the emergence of exciting new trends.

On-demand manufacturing platform Hubs has released its latest 3D Printing Trend Report, which tracks developments and emerging technological trends in the 3D printing industry. According to the report, the 3D printing market saw positive growth between 2021 and 2022, returning to pre-pandemic levels.

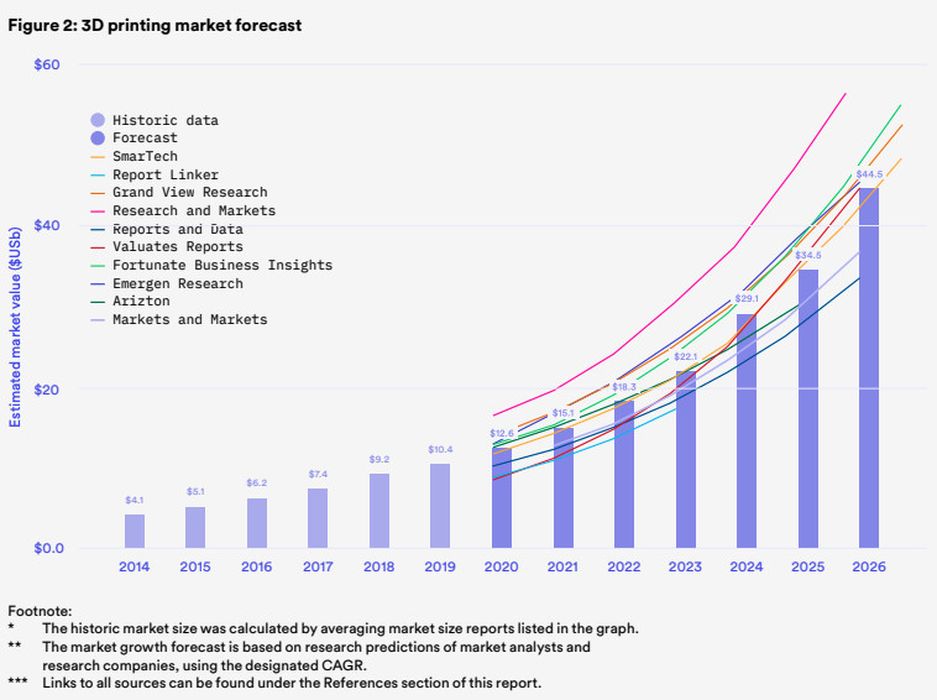

The market reportedly grew by approximately 19.8 percent in 2021. While experiencing a dip due to the COVID-19 pandemic, 3D printing was found to swiftly adapt to production and supply chain needs. The technology enabled more parts and products to be manufactured locally and on demand, showcasing additive manufacturing’s potential to be further adopted into digital manufacturing processes. Of respondents, 68 percent 3D printed more parts in 2021 than in 2020, showing significant market growth. Hubs is forecasting that the 3D printing market will nearly triple in size by 2026, anticipating $44.5 billion in revenue.

As more businesses and manufacturers begin to transition toward integrating Industry 4.0. technologies, the 3D printing market could contribute to making production chains more resilient in the face of global challenges. While 3D printing is widely used in prototyping to accelerate product development, Hubs predicts that the technology will play a supportive role alongside other manufacturing processes in the production of tools, jigs and fixtures. In particular, the technology is expected to see increased integration in the production of end-use parts as well as serial production.

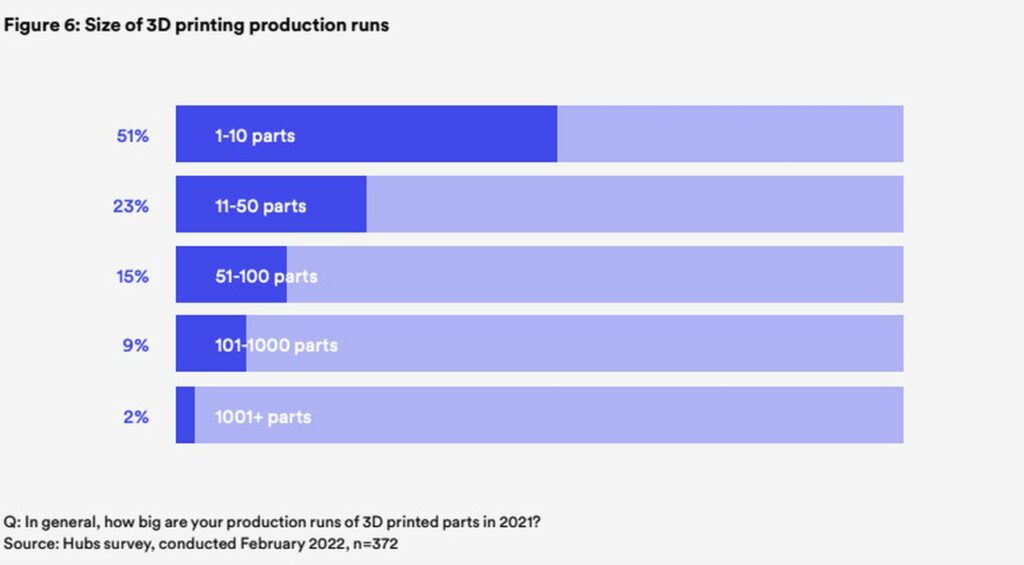

Users have seen increased adoption of 3D printing for higher volume applications, with 49 percent of survey respondents employing the technology for production runs of over 10 parts, compared to 36 percent in 2021. Currently, various industries such as health care, aerospace, automotive and energy are already using 3D printing technology to produce functional end-use parts.

3D printing has also made mass customization accessible to more industries such as the dental industry, which produces patient-specific implants and dental devices. Similarly, digital manufacturing companies have experienced increased demand for part volumes exceeding quantities of 500. According to Hubs, this demand has risen by 163 percent over the past five years. Continuous advancement in 3D printing production is expected to see more serial and mass production applications in numerous industries.

However, Hubs noted that 3D printing is still not currently being used to its full potential, with only 20 percent of survey respondents reporting that they use the technology depending on the geometric complexity it can achieve. The report noted that there are still opportunities to educate users about the potential of 3D printing to create complex geometries for all kinds of parts.

The Hubs report anticipates growth in the following 12 trends in 2022:

- Increased adoption of 3D printing and stronger entry into newer markets

- 3D printing workflow automation and use of collaborative robots, particularly in post-processing

- More robust supply chains and localized on-demand production

- High-performance 3D printing materials development and qualification (refractory metals, ceramics, high-temperature polymers and composites)

- Increased industry partnerships, mergers and acquisitions

- Growth in demand for large-format 3D printing systems, particularly in metal 3D printing

- More sustainable innovation in 3D printing use, design and materials

- Increased use of 3D printing for end-use production and serial production applications

- Improved reliability and repeatability

- Industry standardization, such as adoption of the 3MF file format

- Increased integration of on-demand, just-in-time (JIT) manufacturing thanks to adoption of the Internet of Things (IoT)

- Reduced human intervention between inventory systems and manufacturing capacity

Read more at ENGINEERING.com