Researchers have developed a method of 3D printing single crystal nickel structures.

Crystallinity is a key goal of metal additive manufacturing systems: if the microstructures formed within the hot meltpool are aligned, the part will be much stronger. One way to do this is to encourage the formation of a crystal as the metal cools.

It’s easy to describe a crystal, but much harder to actually make one with a laser system.

There apparently have been research projects that have accomplished this feat, but the results have had limited size and are tricky to do. Often these experiments require a crystal “seed” from which the main crystal grows.

The new research is able to produce relatively large nickel crystals without using a seed at all. They explain:

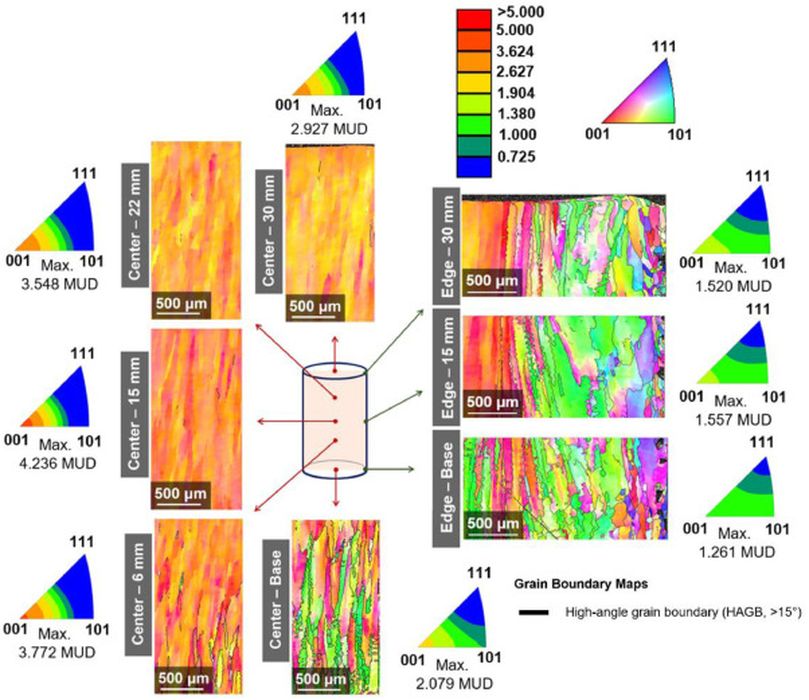

“The exploration of flat-top laser profile in fabricating a single crystal (SX) structure using selective laser melting (SLM) in pure Ni was investigated. Optimization of the parameters led to the formation of a planar melt pool. A homogeneous near-{001}<100> texture with suppressed high-angle grain boundary (HAGB) in high building heights of >20 mm was achieved without an SX seed. In addition, the planar melt pool suppressed the geometrically necessary dislocation accumulation and prevented strain-induced continuous dynamic recrystallization that could cause HAGB formation. Thus, an SX structure with homogeneous near-{001}<100> texture and suppressed HAGB was successfully achieved without an SX seed.”

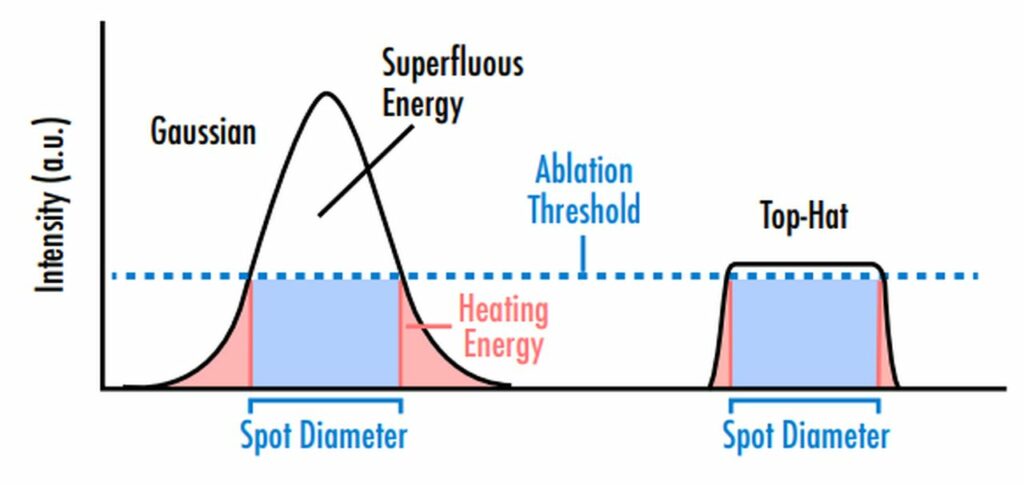

But what is a flat top laser, anyway? It’s a different form of laser. The normal laser type in use is Gaussian, which has a curved peak of energy composing the laser dot, while a flat top has a different profile that produces equal energy throughout the laser dot. This image illustrates the difference:

This research could prove incredibly important for metal additive manufacturing, where considerable effort is spent each day by metallurgists and engineers try to tweak out the best possible print outcomes — meaning the best microstructures.

The ability to more easily create crystalline structures when printing will be attractive. It could be that metal 3D printer manufacturers might take a good look at flat top lasers, if this new process is able to scale.

Via Science Direct