Charles R. Goulding and Preeti Sulibhavi look at how Airbus is leveraging 3D printing to overcome supply chain challenges.

A recent Financial Times (FT) article covered a large production increase planned for Airbus. Airbus is a global leader in the aviation industry and any ramp-up in their production greatly impacts supply chains.

The article in the FT covered how each Airbus aircraft is made up of about 3 million components and these components are from approximately 3 thousand suppliers. Airbus would like to increase the production rate for its A320, the single-aisle aircraft that dominates the market, by 50% to 75 planes per month by the year 2025.

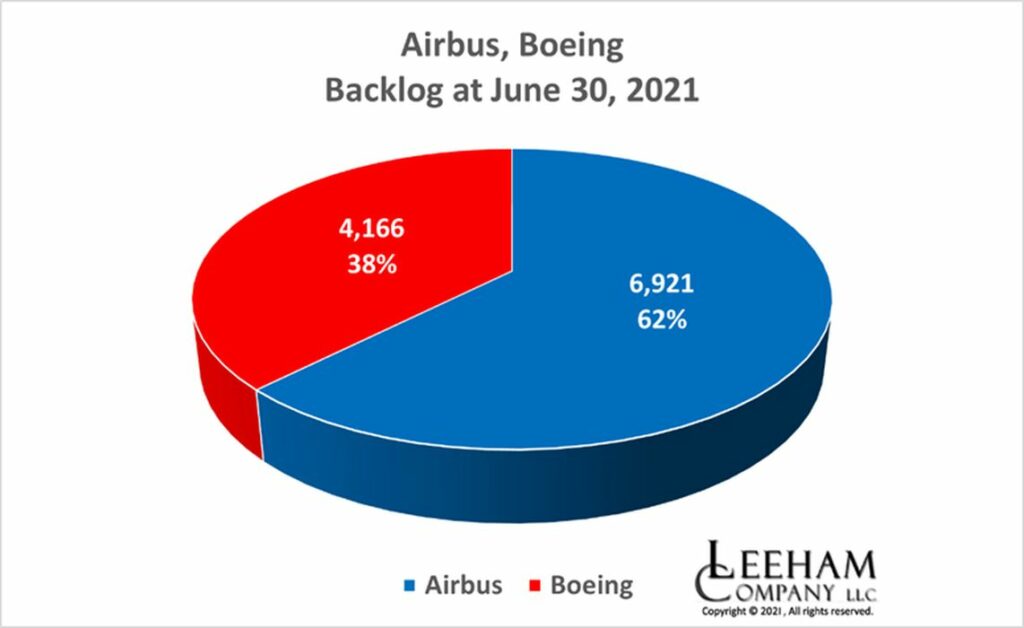

Increasing production by this amount would require Airbus to meet the current demand for new, more energy-efficient models while ensuring that thousands of suppliers can deliver after cutbacks during the Coronavirus pandemic. In the article, Airbus’ CFO, Dominik Asam, admitted that there is “tremendous pressure on the supply chain,” despite securing extensions on vital engine supply contracts. Additionally, Airbus’ competitor, Boeing, is reported to have paused production of its 737 for about 10 days this past May due to supply chain disruptions.

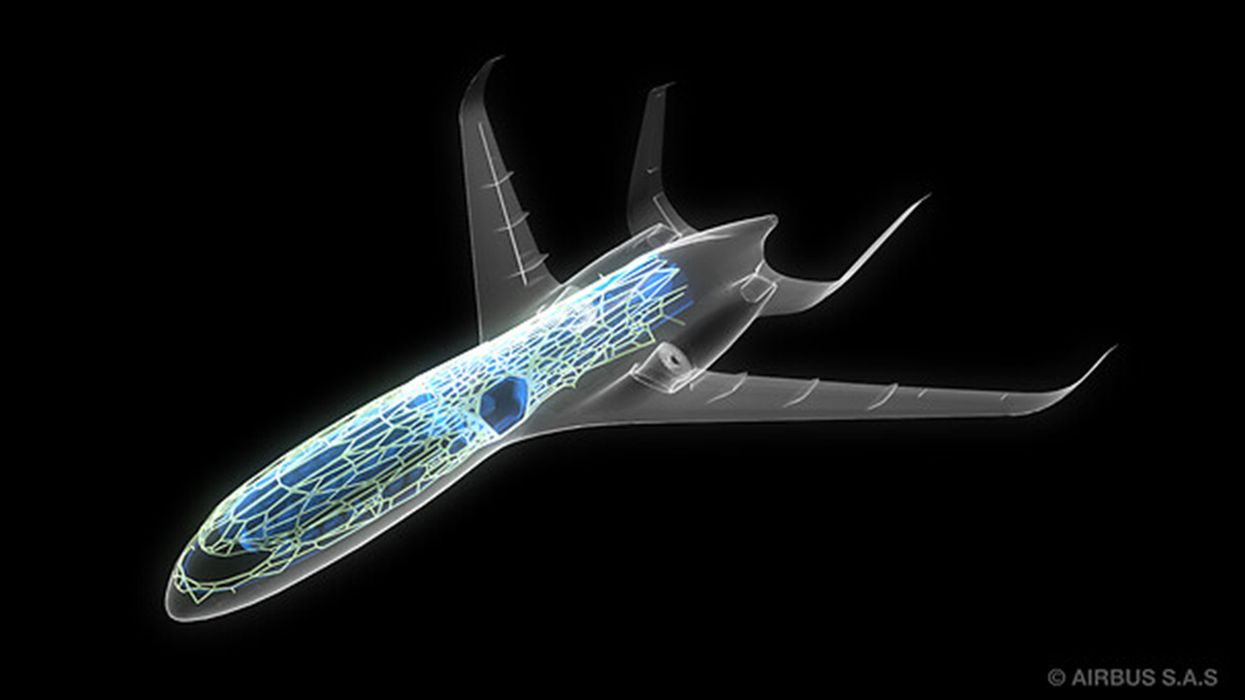

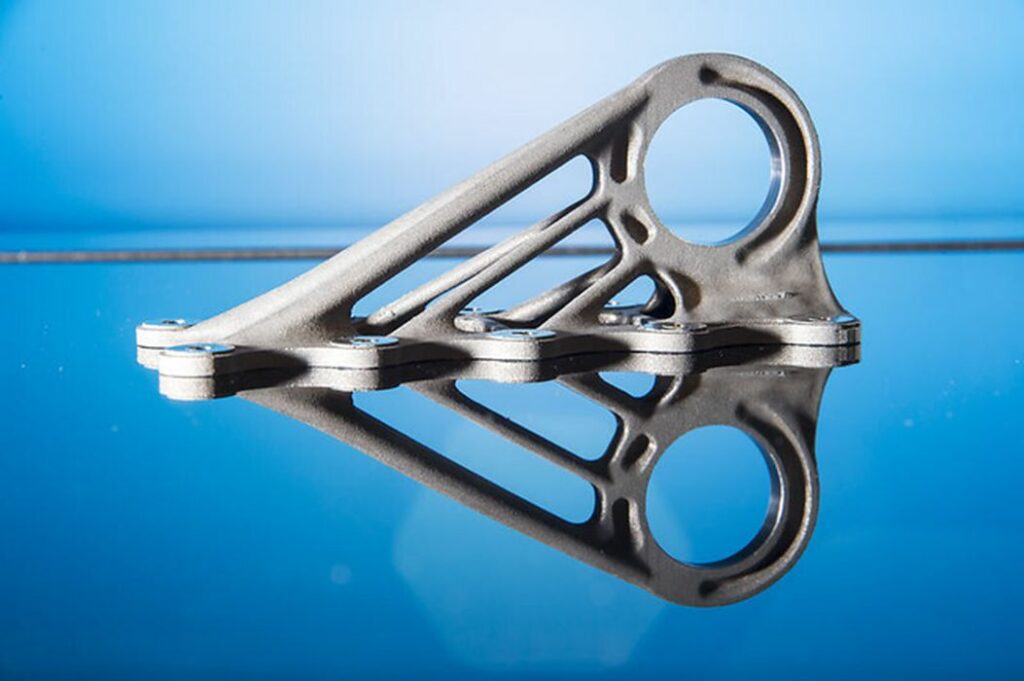

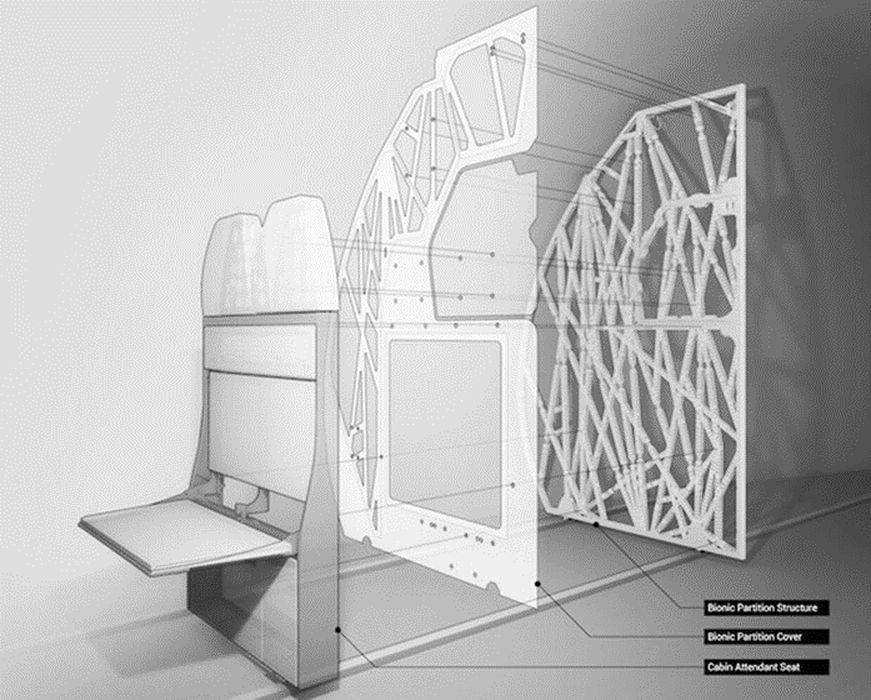

This is where 3D printing comes into the picture. We have previously written about Airbus as well as Boeing and how they have integrated and could further integrate 3D printing into their businesses. Recently, Airbus has fabricated a lightweight, high-strength bionic partition using Scalmalloy, and it is the largest 3D printed component on its A320 series planes.

For this partition, Airbus’ titanium cabin bracket was produced with the help of 3D metal printing. The bionic component weighs 30 percent less than the traditionally milled piece.

It is nice to see the long-term use of 3D printing in an industry leader such as Airbus and also Airbus using its existing 3D printing platform to grow.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing, and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

Airbus is flying high on its recent boost in demand, but it is testing its supply chain integrity. With the help of 3D printing, we believe this can be manageable.