Nanoscribe announced the availability of a new kit to explore 3D printed glass microstructures.

Nanoscribe is a German firm specializing in devices that can 3D print extremely small objects in ultra-fine resolution. They claim to offer the “world’s highest resolution 3D printer”, and they may be correct.

However, the highest resolution is not synonymous with the highest build volume. Nanoscribe’s build volume is rather small, being 100 x 100 x 8 mm on their Photonic Professional GT2 device. Within that small space you can print objects with features as small as 160nm (that’s nanometers, not millimeters).

Nanoscribe achieves this with a two-photon process in which energy is applied within a (small) vat to solidify very small features.

The company provides specialized resins for their 3D printing equipment, and currently they offer or are compatible with a wide variety of material types, including hydrogels, composites and much more.

But now there’s a new material in their portfolio: glass.

But how do you 3D print glass? Isn’t that a rather difficult material to 3D print? It is, and many have tried to do so using very high temperature devices. However, one materials manufacturer invented a method of doing so very easily.

We’ve covered them previously: Glassomer. The startup company developed a photopolymer resin that can be used to produce glass objects.

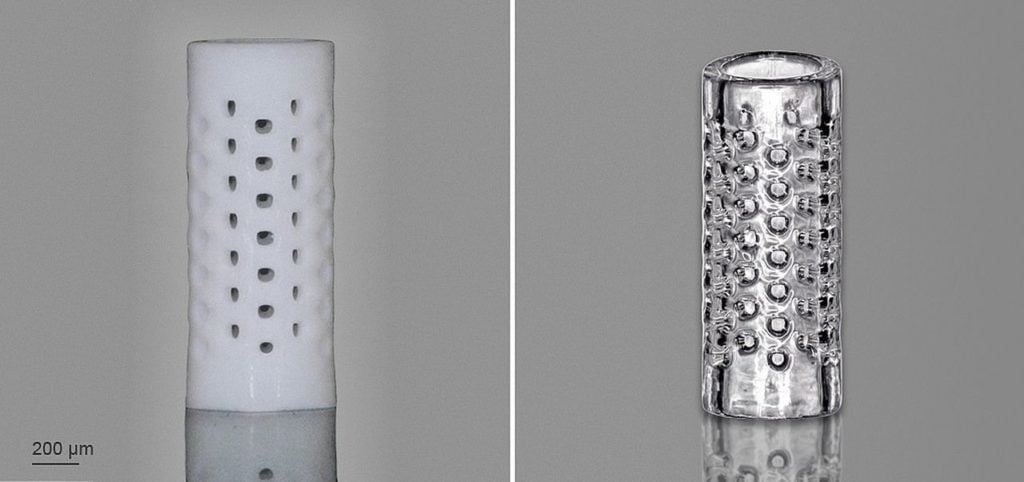

The secret to their resin is that it is actually made of 60% glass nanoparticles. While the resin itself appears clear, it can be solidified using SLA, DLP or similar 3D printing processes into effectively pure glass objects. Of course, this requires a post-processing step where the raw print is subjected to a 600C to burn out the binder, and a second post-processing step at 1300C to sinter the remaining glass particles together.

It’s a fascinating material and now it’s available for Nanoscribe equipment via a new “Glass Printing Explorer Set” from the company. Nanoscribe explains the product:

“With the new Glass Printing Explorer Set, Nanoscribe presents the first commercially available high-precision additive manufacturing process and material for 3D Microfabrication of fused silica glass microstructures. The new photoresin GP-Silica is the centerpiece of the Glass Printing Explorer Set and and was developed in a joint research project with Glassomer. The world’s only photoresin for fused silica glass microfabrication stands out due to its high optical transparency combined with excellent thermal, mechanical and chemical properties. This opens up opportunities in exploring new applications in life sciences, microfluidics, microoptics, material engineering and other microtechnology fields.”

Microstructures are a new field that has yet to be fully explored, as it is relatively difficult to produce such small objects unless using equipment such as Nanoscribe’s.

With the introduction of glass material, it is likely there will be many new innovations appear in the space. But before that can happen, inventors must explore the use of the material and that’s where this new product is targeted.

Via Nanoscribe