Charles R. Goulding, Jacob T. Nolan and Preeti Sulibhavi discuss the US Department of Defense’s strategic integration of 3D printing.

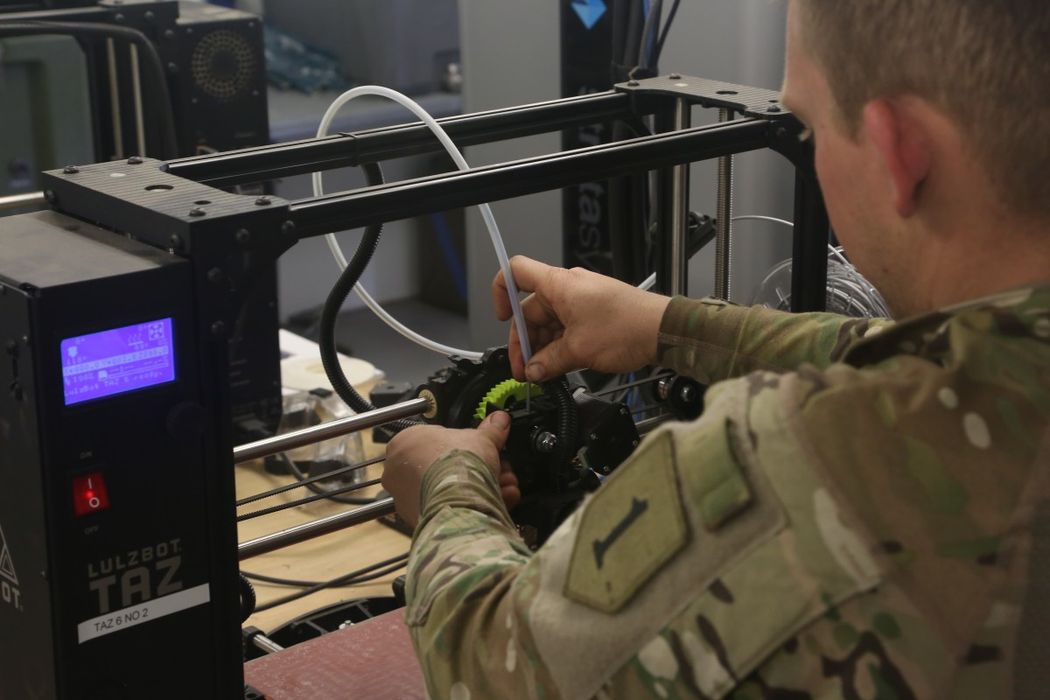

The Department of Defense (DoD) has increasingly begun using 3D printing technology in training, operations and in the field. Over the past few years, the government has been looking for new ways to help improve soldier safety. 3D printing can be used to repair and maintain weapons, defense systems, as well as military vehicles.

The Maintenance, Repair and Overhaul (MRO) opportunities for the 3D printing industry in the aerospace/defense industry include the production of spare parts and replacement parts in the field.

There are also a myriad of opportunities for fabricating replacement parts and components in real-time in the field for military equipment and transport vehicles.

There are also 3D printing opportunities for weapons and ammunition. The Army is looking into 3D printing ammunition for grenade launchers. The ammunition will be intended for the Rapid Additively Manufactured Ballistics Ordnance (RAMBO). The RAMBO grenade launcher is made up of 50 parts. All the pieces for the RAMBO besides the springs and fasteners were manufactured using 3D printing. Each piece of the grenade launcher was produced using a variety of materials and manufacturing techniques.

The US Army has supported the use of 3D printing technology and has been deploying it in a tiered approach. The three main levels are fabricating units, support & maintenance, and the Organic Industrial Base (OIB).

At the unit level, 3D printers can empower soldier innovation and enhance readiness by producing accurate models and training aids, such as realistic scale model buildings for improving rehearsals at both individual and collective training events. Commanders will decide when and how to use the 3D printers, within policy, training, and certification limits as defined in military protocols, as well as points of contact for assistance.

At the support maintenance level, Army tooling sets and kits will include a polymer 3D printer and scanner combination that equip the US military with a new and flexible tool for producing battle damage assessment and repair parts on an emergency basis.

At the highest echelon of the Army’s operationalized 3D printing capabilities, the depots, arsenals, and ammunition plants of the Army’s Organic Industrial Base have developed strong 3D printing technologies. The 3D printers on bases have helped internal production lines to overhaul, rebuild, and reset Army equipment. The Advanced Manufacturing Center of Excellence (AM COE) at Rock Island Arsenal’s Joint Manufacturing and Technology Center (JMTC) furthers these capabilities by serving as a focal point for operationalizing 3D printing across the Army. It can provide 3D printed polymer or metal parts directly to the customer in support of the readiness needs of the Army.

The Pentagon can leverage 3D printing technology among other emerging technologies to keep pace with global defense competition. While 3D printing technology is advancing, the deployment of 3D printers poses a challenge for the US DoD.

The commercial and defense industries should be developing printers that can recognize conditions and adjust printing as necessary or find a way to more closely integrate monitoring into the printing process, Benjamin Leever, Director of Manufacturing and Industrial Technologies for the Air Force Research Laboratory, explained to the National Defense Magazine.

Additionally, humidity and composition can affect how parts can turn out in different locations when operating in the field.

The private sector has traditionally played a large role in developing and advancing 3D printers. Companies were responsible for approximately 90 percent of all 3D printing patents from 2015 to 2019, according to a Congressional Research Service report, “3D Printing: Overview, Impacts, and the Federal Role.” Companies like Seurat, MAKELAB, Desktop Metal, and MarkedForged have the opportunity to increase their defense projects and increase their metal 3D printing research and development. The 3D printing industry has a real opportunity to help support our national defense and improve the quality and efficacy of the military equipment that soldiers in the field have to depend on.

The Research & Development Tax Credit

The now permanent Research & Development Tax Credit (R&D) Tax Credit is available for companies developing new or improved products, processes and/ or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

The US DoD is a global example of the defense industry. By integrating 3D printing technology, it sets an excellent example to the world of how innovation can fuel our defense systems. 3D printing technology is continuously improving and is a necessary investment for helping to ensure national defense and safety.