Charles R. Goulding and Preeti Sulibhavi take a closer look at BAE Systems’ recent acquisition of Ball Aerospace and how 3D printing can play a role.

BAE is the UK’s largest defense contractor with a substantial US manufacturing presence. That US presence is about to become much larger with the proposed acquisition of Ball’s aerospace business for US$5.5 billion. BAE has annual sales of US$26 billion and the US government is its largest customer.

The business includes munitions, security, and aerospace products. The Ball Aerospace business has US$3 billion in revenue and a US$5 billion backlog. BAE has recently been reporting very strong operating results.

Although the acquisition of Ball involves critical assets important to US security this acquisition may get regulatory cover from the historical “special relationship” the US has with the UK.

Ball’s space business has some unique capabilities and space product design production is an area where 3D printing plays an important role.

Aerospace/Defense and 3D Printing

The opportunities for 3D printing applications in the aerospace/defense industry are vast. We have covered space rocket pioneers revolutionizing space as well as the use of 3D printing technologies in space. The astronauts benefit from 3D printers in space. They allow astronauts to manufacture anything they need on-demand during their missions. Keeping a supply chain from Earth to the ISS is costly and slow. This is a cost-effective and quick workaround for replacement parts for everything from rocket engines to interior parts.

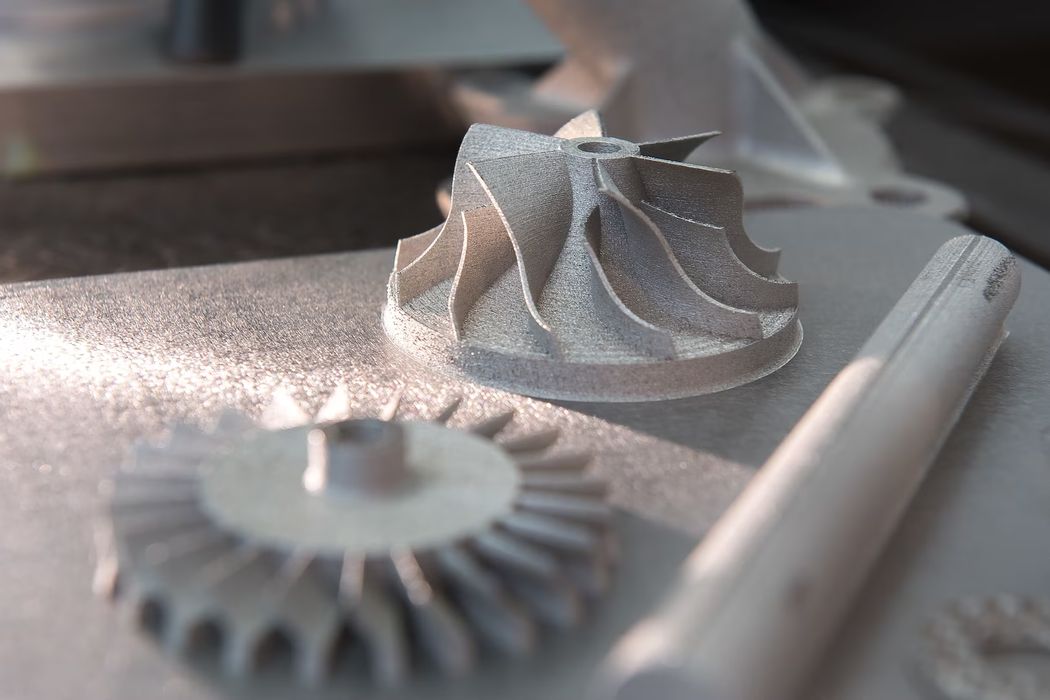

Both metals and nonmetals aerospace parts can be manufactured using 3D printers. Items include aero-engine components, turbine blades, and heat exchangers. Non-metallic methods of 3D printing have been used for the rapid prototyping of parts to create fixtures, and interiors made of plastics, ceramics, and composite materials.

Aerospace and defense parts must be highly durable, temperature-resistant, and function in various environments. 3D printers are already being used to create parts for the aerospace/defense industry. We believe this trend can shift from the prototyping phase to production in the coming years.

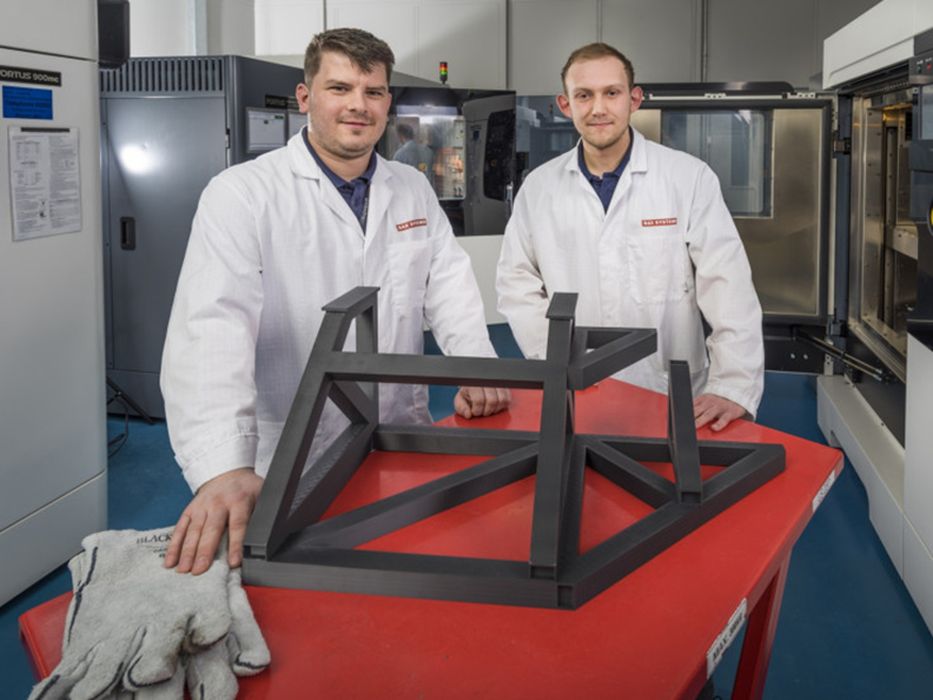

BAE is building the new Tempest next-generation fighter aircraft with 30% 3D printed parts. This is consistent with the UK government’s Combat Air Strategy which aims to deliver cost-effective strategies for defense programs. 3D printing helps BAE Systems meet that government goal by significantly reducing manufacturing costs compared to traditional methods.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

The fact that BAE Systems acquired Ball Aerospace illustrates how closely aligned the aerospace and defense fields are. The next frontier in terms of national defense is space. The 3D printing industry can help the stars align for both these markets.