3DEO announced some startling statistics about their recent expansion, but this demonstrates something important for 3D printer manufacturers.

If you’ve not heard of 3DEO, they are a Los Angeles-based company providing metal 3D printing services. We first ran across the then-startup company in 2017, when they were showing samples of their process at a trade show.

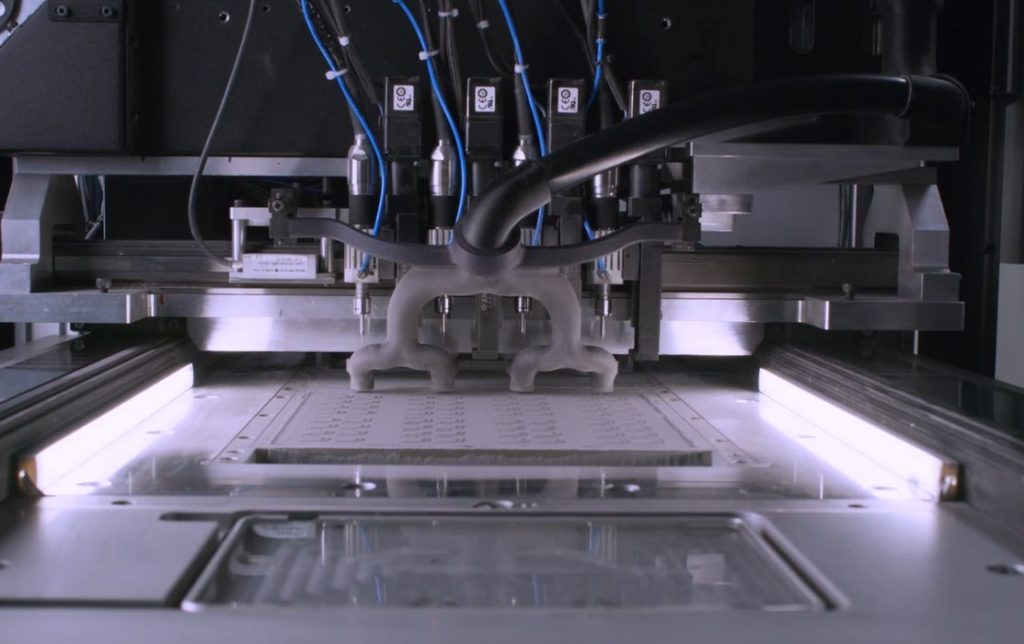

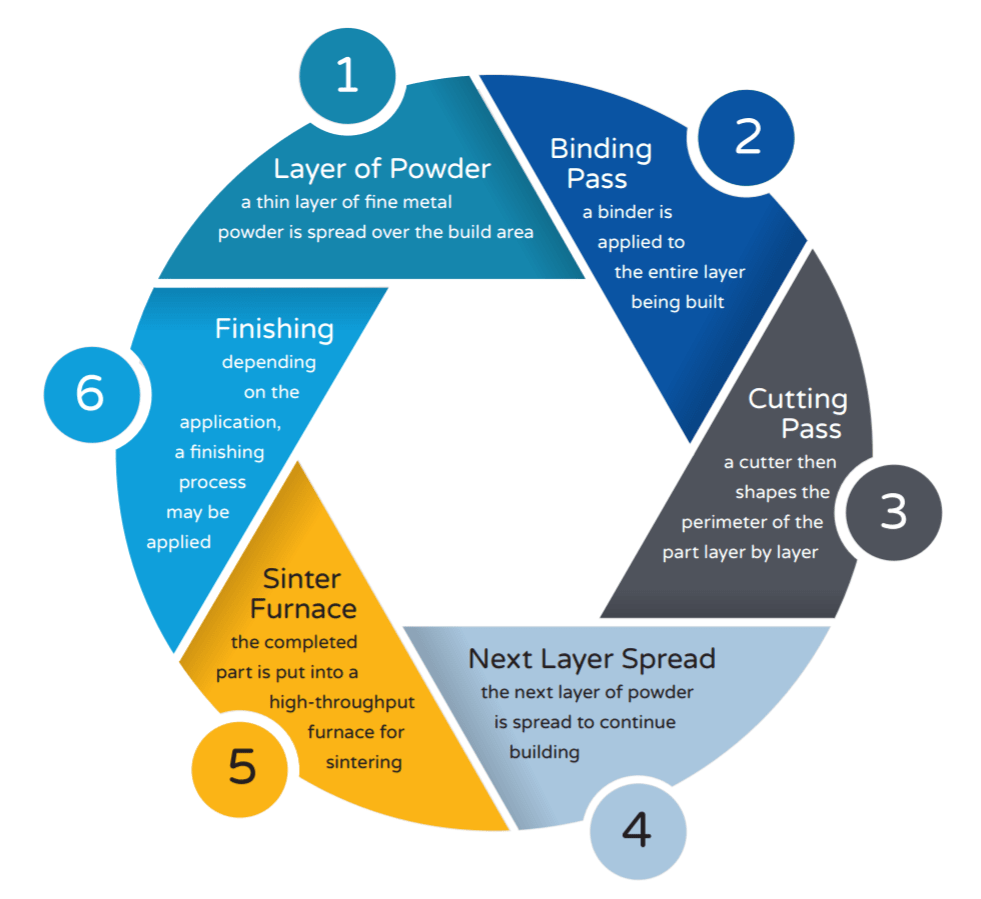

They explained their 3D printing process is a binder jet approach that uses commonly available metal powders. This is far less costly to produce metal parts, but seems to be limited in size to relatively small parts.

The parts were quite impressive, but they didn’t show us their proprietary 3D printer. This is because they have a different strategy from most 3D printer manufacturers.

The typical 3D printer producer intends on marketing their products directly or indirectly to buyers that would operate the equipment. Most manufacturers target a particular niche and optimize their equipment around that domain.

This is not what 3DEO decided to do. They could have manufactured their device and sold it to customers, but that would have required them to develop comprehensive customer support services, training systems and documentation, etc. Rather than incur that expense, they would instead operate the machines themselves on behalf or clients that would request parts to be produced.

That was a risky decision, as it isn’t the normal approach for the developers of a new 3D printer. They decided to market their technology as a service to users requiring the production of medium-volumes of small-sized metal parts.

So how has it worked out for 3DEO?

For starters, they produced their one millionth customer part in the middle of 2021. That tells you how successful their strategy has been.

But now there’s more news.

3DEO announced they’ve expanded their central facilities in Los Angeles. Today their manufacturing floor is an incredible 80,000sf (7500sm), equipped with no less than 37 of their proprietary 3D printers. This has to be one of the largest metal AM setups in the world, at least in terms of the number of printers.

In addition, they nearly doubled their staff complement in 2021, now at 175. This total includes 33 engineers, who work directly with the proprietary 3DEO technology. By the way, that tech is protected by 20+ patents.

That’s an incredible achievement, but what can they do in 2022 to top that? 3DEO explained:

“The company currently has 37 printers in production with plans to add 44 additional printers into production in 2022 – nearly one printer per week. The expanded facility has enough space to accommodate 125 printers, making way for continued growth beyond 2022.”

They expect to triple their business in 2022.

Now that’s what you could call explosive growth.

Does the “operate the technology in-house” strategy work? Apparently so, with great effect.

This is a point that should be considered by others currently developing their own new 3D printing technology. You don’t have to sell machines to succeed.

Via 3DEO