Authentise announced a rebranding that is a lot more than a name change.

The company has been developing their manufacturing execution system for additive manufacturing for around a decade now, and it’s become quite comprehensive and functional. One of their clients, Boeing, stated that it saves them an amazing 94% on time and generated significant ROI.

The system works by integrating data from various components of a manufacturing workflow, applying advanced techniques including machine learning, and providing a clear lifecycle for a product or part to be produced. Modern factories increasingly use this approach to maximize the use of their capital-intensive equipment and thus generate ROI.

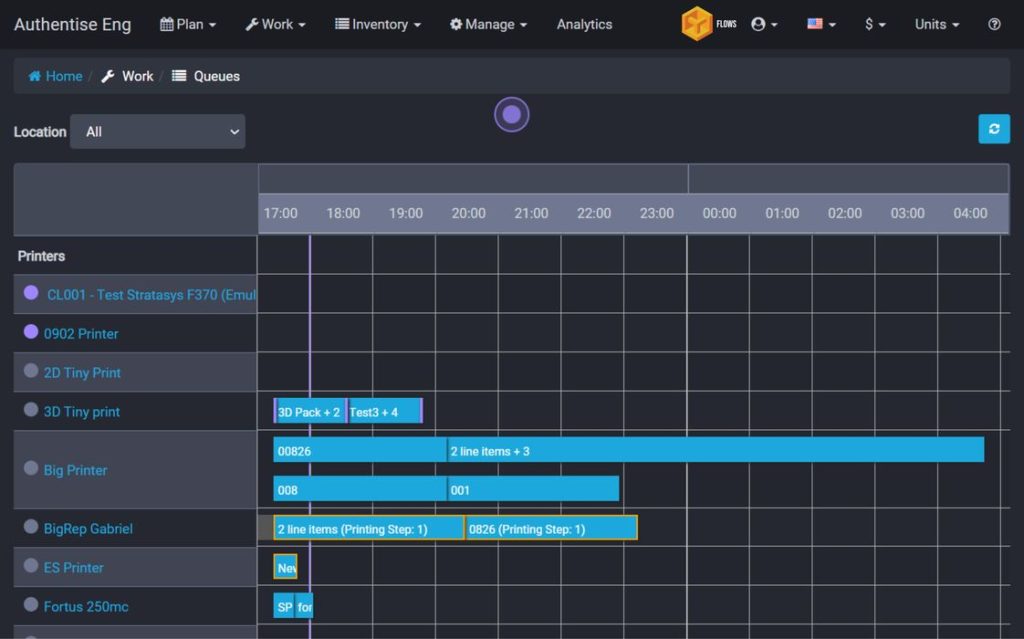

For some years, Authentise’s flagship product was “aMES”, a manufacturing execution system focused on additive processes. This tool would queue jobs and intelligently dispatch them to available equipment and provide traceability and monitoring throughout. It’s one of several growing MES tools available today, but I believe it was one of the first on the market.

The news is that they are rebranding aMES to “Flows”. Flows will be a manufacturing system for all types of manufacturing, beyond additive manufacturing where the company made its start. They will also market “FlowsAM”, which is a version of Flows specific to additive processes.

Why build Flows? It turns out that the additive manufacturing process involves more than just the “printing” part. Printed parts must be post processed in a variety of ways with non-additive equipment. By handling these processes, Authentise became familiar with non-additive processes and positioned them to formalize that knowledge as Flows.

Authentise CEO Andre Wegner said:

“We have long sought to use our experience in the additive sector to fuel digital manufacturing as a whole. Additive has key advantages that make it a fertile sandbox, such as more data, less legacy, and focus on lot size 1. That ability to manage agile operations is increasingly in demand as the world moves to address recent supply chain failures. That is why we’ve chosen this point to release Flows and FlowsAM.”

Flows includes not only the manufacturing functionality, but also includes other necessary functions. Authentise explains:

“Flows incorporates many tools that stretch beyond the capabilities of a traditional Manufacturing Execution System, including real-time quoting, machine-data driven status updates, material genealogy, supplier management and more. These features are already used to manage post processing such as heat treatment, machining and more.”

For Authentise, this is an enormous strategic step. It creates a potential trajectory into a much larger market, well beyond additive manufacturing, which could enable significant growth in their operations.

Authentise said FlowsAM is available today, while they expect the Flows product to become available some time in 2023.

Via Authentise