COBOD released an online construction 3D printer Configurator, the first I’ve seen from any provider.

Construction 3D printing is at the cusp of a huge boom. Multiple parties are now producing effective 3D printing options that can produce various sizes of concrete building walls and foundations.

I have to take a moment to once again point out that a construction 3D printer does not “3D print a house”. It merely produces the concrete portions of the house, which could include foundation, walls, floors and possibly decorative elements. The remainder of the structure must be completed using conventional building trades. However, the construction 3D printing technology can speed up the entire process and allow for easy production of designs that would be cost-prohibitive if made using traditional methods.

Construction 3D printers are typically very large devices as they typically work outdoors on the building site: it is rather difficult to move an enormous concrete print once complete.

These machines currently take two forms: using robotic arms or using a cartesian-style gantry system, much like smaller 3D printers — except they are massively larger.

COBOD is one of the leading producers of construction 3D printers, with their BOD2 device. It has been used to build many different buildings on several continents, and is one of the very few that can manage to 3D print multiple-story structures.

Up until now the BOD2 specifications and some images were about all you could know about this device, unless you were on location at a build site. Now COBOD has released an interactive “Configurator” that shows very clearly how the BOD2 is put together, and the options one can choose from when placing an order.

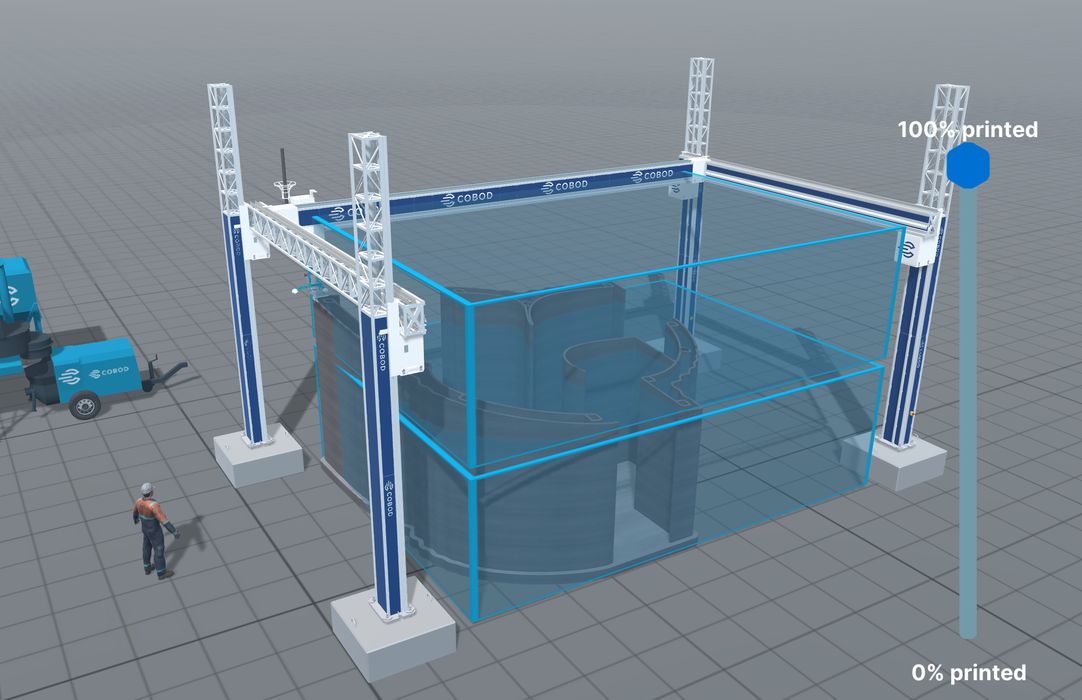

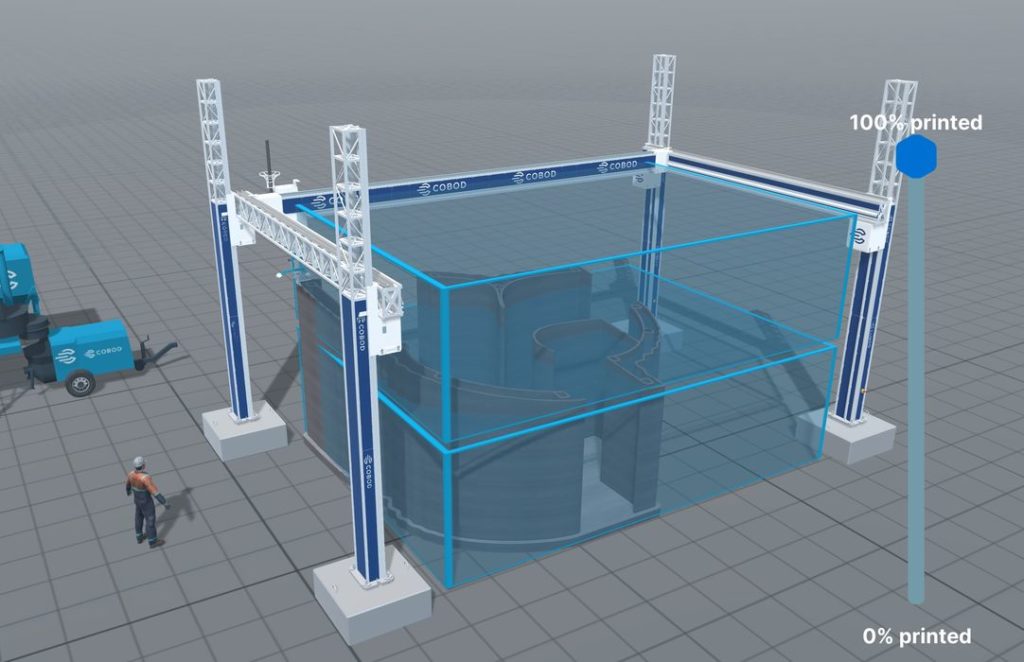

The Configurator shows a simulated 3D view of a build site with the BOD2 in position for printing. The user is allowed to set several parameters used to “build” the BOD2.

You can select the number of “modules” for width (X-axis), length (Y-axis) and height (Z-axis). Changing these immediately adjusts the online view and shows you what the corresponding BOD2 device would look like.

What’s impressive is the potential size of the system. The X-axis can accommodate up to five modules, yielding a maximum X-axis length of 12.1m. The Y-axis can take up to 20 (twenty!) modules for a length of an amazing 50m. Finally, the Z-axis can hold up to four modules, reaching a maximum build height of 9.1m.

The smallest configuration, with two modules on each axis, can print a one-story building of 21sm, or 4.5 x 4.5 x 4.1 m build volume.

The largest configuration, which is truly gigantic, can print a three-story building of 1815sm total floor space, within a 12.1 x 50.0 x 9.1 m build volume.

(Note, for those still using imperial units, there is a toggle in the Configurator to show them.)

Another interesting feature is the “3D Print a Building” button. This displays nine different construction 3D printing projects that COBOD has actually executed successfully in real life. If you select one of them, the Configurator immediately resets to the machine setup used for that project.

Even better, the Configurator can actually simulate the entire print job, much like is done in desktop slicing software, layer-by-layer.

While this is all fun to play with, there is a much more serious purpose behind the Configurator.

COBOD makes the printers, but they are not a building company. For that skill they partner with actual building companies who would then use their equipment on customer projects.

However, like all 3D print technologies, COBOD faces a challenge in persuading these companies to adopt an entirely new and strange technology. They need to develop sophisticated education programs that can help turn attitudes and enable more printer sales. The Configurator, I believe, is one part of that educational cycle.

While you likely won’t be operating a construction 3D printer yourself, it is fun to pretend with this Configurator.

Via COBOD