Charles R. Goulding and Preeti Sulibhavi look at the potential use of 3D printing technology to improve the efficiency of CHP operations.

Combined Heat and Power (CHP), also referred to as cogeneration, is an energy-efficient, single fuel method of power generation. On-site electric, heating and cooling power sources are provided from a single fuel source. CHP reduces fuel use by avoiding losses with conventional electrical supply and eases grid congestion when power demand is high all while avoiding the need for new distribution infrastructure.

The US Inflation Reduction Act (IRA) presents new substantial tax incentives for CHP, including an increase in investment tax credits from 10% to potentially 40% at up to US$5 per square foot on EPAct tax deductions.

The equipment providers include many leading manufacturers and some niche specialists. An example of a niche manufacturer is Tecogen of Waltham, Massachusetts. The industry is not immune to supply chain component challenges which currently may be the only impediment to unparalleled sales growth. Increased utilization of 3D printing technology is the solution to some of the component supply chain issues.

The good news is that many of the leading manufacturers such as GE, Caterpillar and Siemens all have substantial 3D printing capabilities.

3D printing should not overlook a huge opportunity here. There are many reasons why 3D printing can play a pivotal role in the advancement of the CHP industry.

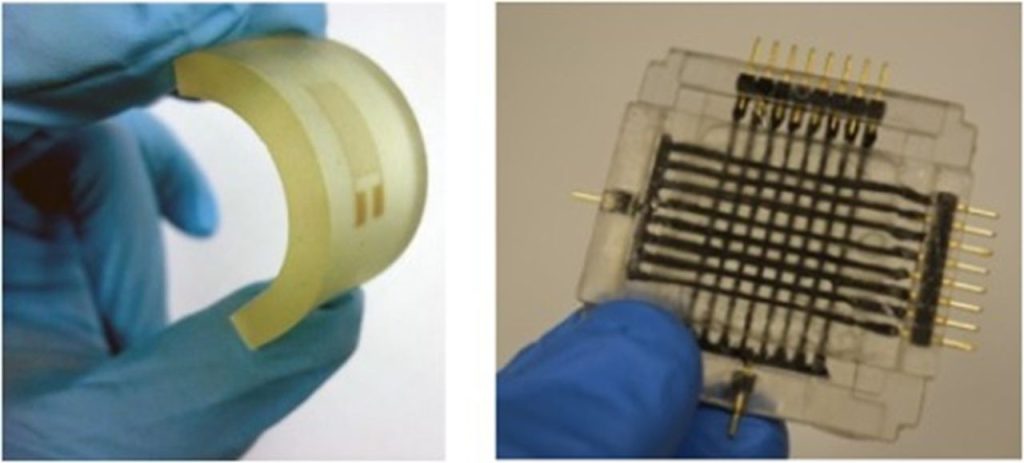

Components required by CHP systems include a prime mover, a generator, heat recovery equipment and electrical interconnections. There are control, sensing and monitoring systems as well. These can be 3D printed.

The Research & Development Tax Credit

The now permanent Research and Development (R&D) Tax Credit is available for companies developing new or improved products, processes and/or software.

3D printing can help boost a company’s R&D Tax Credits. Wages for technical employees creating, testing and revising 3D printed prototypes can be included as a percentage of eligible time spent for the R&D Tax Credit. Similarly, when used as a method of improving a process, time spent integrating 3D printing hardware and software counts as an eligible activity. Lastly, when used for modeling and preproduction, the costs of filaments consumed during the development process may also be recovered.

Whether it is used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Conclusion

CHP is a proven technology for energy generation and building energy efficiency. A potential US$50B market is worthy of attention. The 3D printing industry has the opportunity to participate in this growth while helping to reduce energy usage and emissions.