This week’s selection is the Bubble Glider by the folks at ViralVideoLab.

This YouTube channel posts unusual experiments in small build projects, such as infinity loops, siphons, paper airplanes and such. One video attracted our attention as it made good use of 3D printing.

The Bubble Glider is a one-piece 3D print that actually flies. But its most notable feature is that the wings are made from water!

Actually, water doped with a bit of dish soap to be perfectly clear, but water nonetheless.

The concept is derived from those rings used to create soap bubbles. When they’re dipped into a tub of soapy water, surface tension forms a planar surface of water around the ring. Then, bubbles ensue.

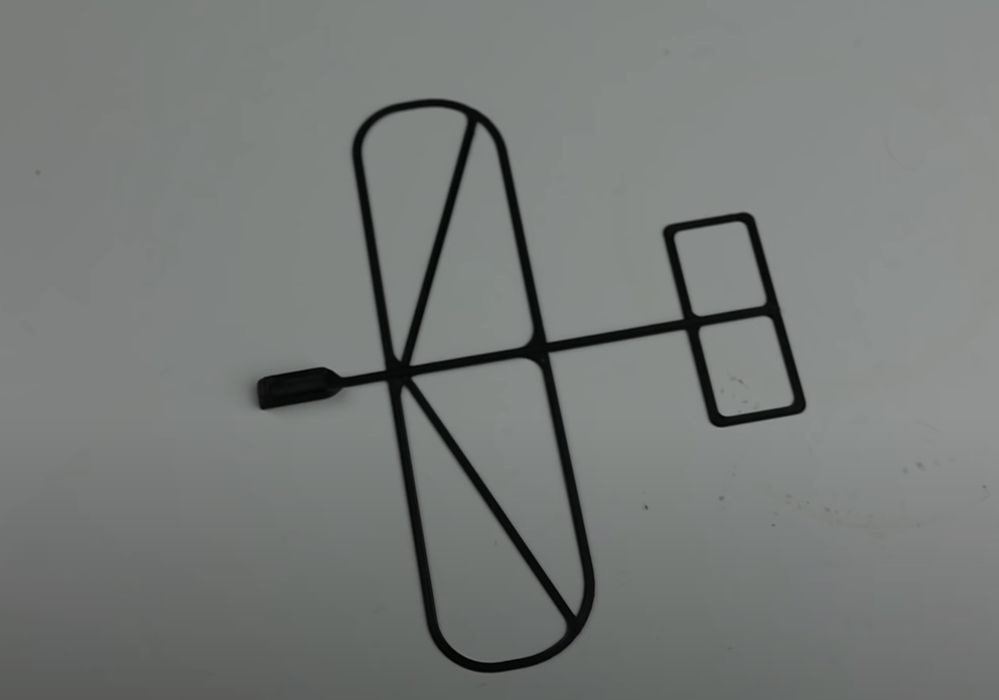

Here the same principle holds for the wings, which are in fact a series of interconnected “rings” to capture similar soapy surfaces.

The glider is first 3D printed, and the structure is entirely flat. While this makes for an incredibly easy — and fast — 3D print job, it also means there is a bit of work to do after printing: flat airplanes don’t fly.

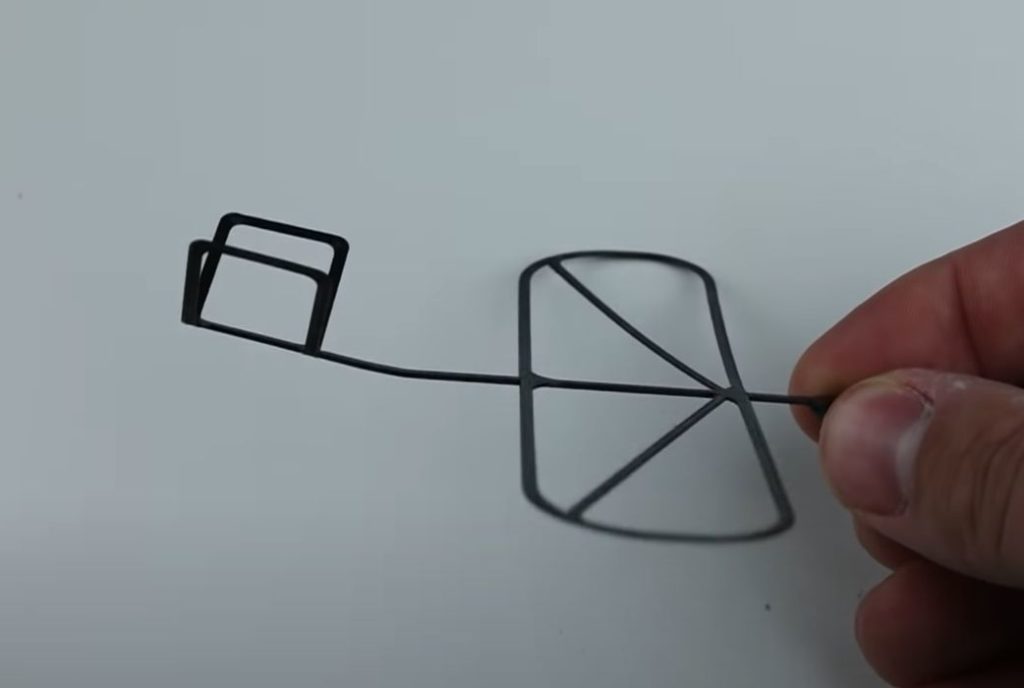

This is done with some manual effort to twist the tail into position, as shown here.

While you could 3D print this shape correctly, it’s pretty easy to do the bending afterwards. This also permits the aviator to introduce turns by bending the tail appropriately.

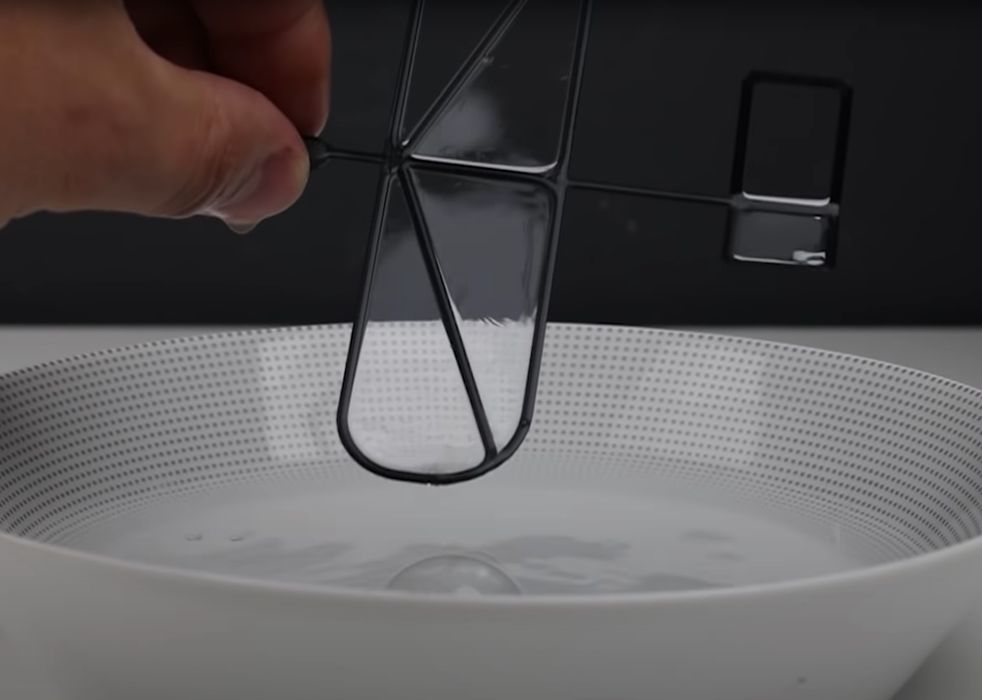

Once in flying form, the glider is dipped into a bowl of soapy water, and as expected the wings immediately form. The aircraft is then ready for flight.

In the video you’ll see how well this glider flies. I suspect it’s because of the incredibly lightweight structure made from only a few layers of PLA and a tiny bit of water. Of course, it won’t fly forever, as the water will “pop” and you will crash.

ViralVideoLab explains the project:

“The experiment is very interesting because the iridescent interference pattern is an indication that the “covering” of the wing has a layer thickness of less than one µm. Turbulence and aesthetic moving patterns are caused by hydrodynamic instabilities, in which the Marangoni effect most likely plays an important role. The really interesting thing is the surface tension of the water, which is so great that it can be used to cover a wing. Similar to soap bubbles, the surface tension has to be reduced somewhat so that a stable film can be formed. This is achieved by adding detergent.”

While they don’t post the 3D model for the glider, it can be purchased on eBay for €10 (US$11.50).

ViralVideoLab is already building different styles, as you can see in this followup video:

Most Fabbaloo readers may simply design their own equivalent bubble glider by using the same principles. It could be an interesting project to experiment with different wing and fuselage designs, and this could be done very quickly due to the short print time. How big an aircraft could be made in this way?

Someone will find out.

Via YouTube