This week’s selection is the Electronic Component Bender by Luigi Ruina.

Ruina designed and 3D printed a tool that saves him an enormous amount of time.

But what does this rather simple tool do? Just watch this video:

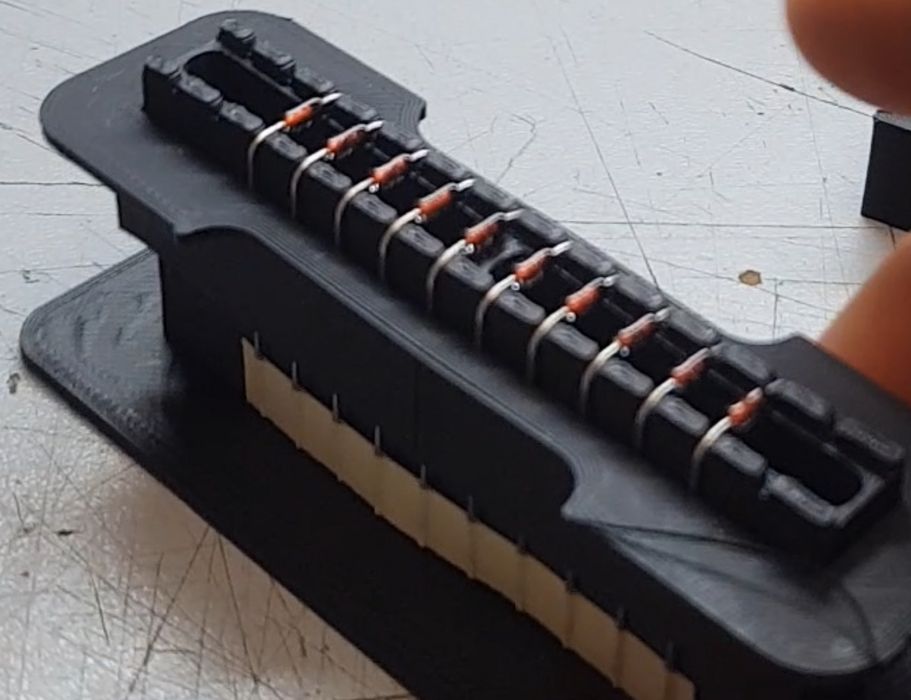

The Electronic Component Bender takes a set of fresh electronic components and bends them perfectly for insertion into a PCB. Normally this is done manually — and inaccurately. If Ruina is building many PCBs, then I can imagine this tool would save an incredible amount of time and frustration.

Ruina has made the STL files available on Thingiverse for free download. There are only two parts, as you can see, and they’re quite easy to 3D print.

I’m quite inspired by this design, even though it is quite straightforward.

First, Ruina has leveraged 3D print technology to solve a problem that few would even realize was required. But once used, this is clearly the way to go forward. Even better, Ruina solved the problem with an incredibly simple design.

Secondly, you might ask “what if the distance between the bends has to be different?” That indeed could occur, as electronic components come in various sizes. The answer is simple: repeat the solution: redesign the original model to have the required span.

If you can fix a problem once, you can do it again.

Finally, once you’re in that mode, look out, because there are always more problems to be solved.

The result is a problem space where you are throwing issues at 3D technology and solving them continuously.

That’s a world I like.

Via Thingiverse and Reddit