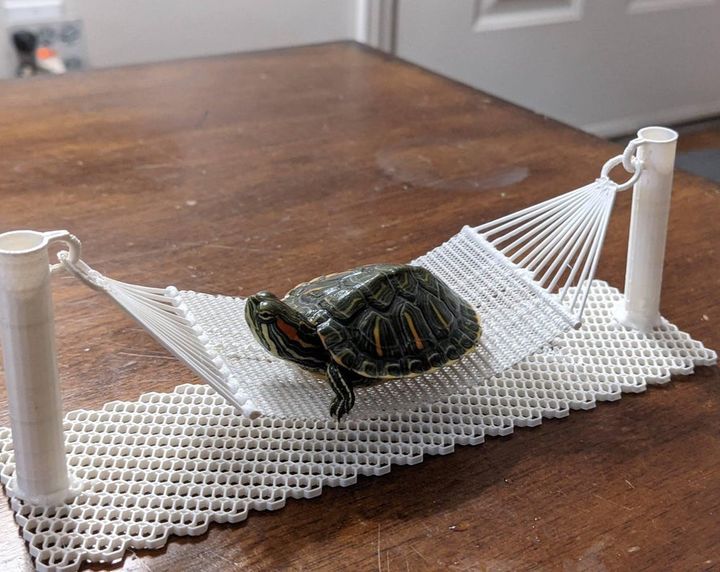

This week’s selection is the questionably useful, but totally admirable Mini 3D Printed Hammock by Instructables contributor jayleenli.

Everyone needs a Mini 3D Printed Hammock, am I right? You simply have to have a comfy 3D printed spot for your turtle or other small amphibian to sit in the warm sun.

Well, perhaps not, but this is a fascinating project nevertheless.

Instructables contributor jayleenli did not design the hammock in a conventional CAD tool, nor does she provide the usual 3D printable STL files for the project.

Instead, this is an exercise in generative design.

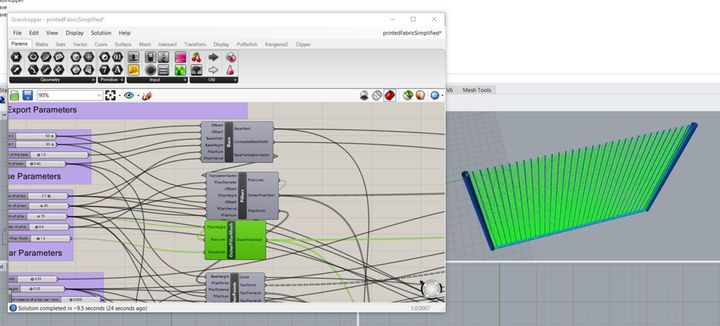

jayleenli decided to use the standard Rhino 3D / Grasshopper combination to perform the generation. Rhino 3D is a popular 3D CAD solution, while Grasshopper is an associated product that provides an interface for designing generators.

You can see here how Grasshopper works. It’s essentially a flowchart of steps that combine mathematical and 3D operations in a specific sequence. By devising an appropriate chart, Grasshopper will generate a highly complex 3D model.

The benefit of using a solution like Grasshopper is not only that you avoid the tedious work of creating the complex structure by hand, but also it’s parametric: you can adjust the parameters in the Grasshopper steps to alter the outcome, either subtly or dramatically.

But in a highly unusual move, jayleenli decided to not have Grasshopper generate a 3D model, but instead generate the GCODE required to 3D print the 3D model. This approach avoids the need to use slicing software entirely.

jayleenli started with an existing Grasshopper configuration that generated GCODE to produce a fabric-like structure. She then iteratively modified the code to eventually generate all pieces of the hammock, including the comfy fabric-like portion.

I say iteratively, because this style of 3D model generation has diminished ability to “see” the output before 3D printing. To achieve the final design, over twenty attempts and tweaks were required.

The GCODE was able to successfully 3D print the hammock parts on an Ender 3 3D printer, and jayleenli could assemble the parts into a usable hammock, as seen in this video:

In an epic Instructables saga, jayleenli describes in considerable detail the struggles she had to overcome difficulties in coaxing the correct GCODE from Grasshopper. She has also provided a Google Drive link where you can find her Grasshopper files for free download. Tweaking these files will get you started on your own hammock project.

While you might not require a hammock for your turtle, the exercise in building one will greatly increase your understanding of GCODE and generative design.

Via Instructables and Google Drive