This week’s selection is the incredible Nissan Ariya replica made by Ogle Models.

UK-based Ogle Models is a 65-year old firm that provides sophisticated modelmaking and prototyping services. The company uses a variety of advanced making equipment to complete client work, including 3D printing.

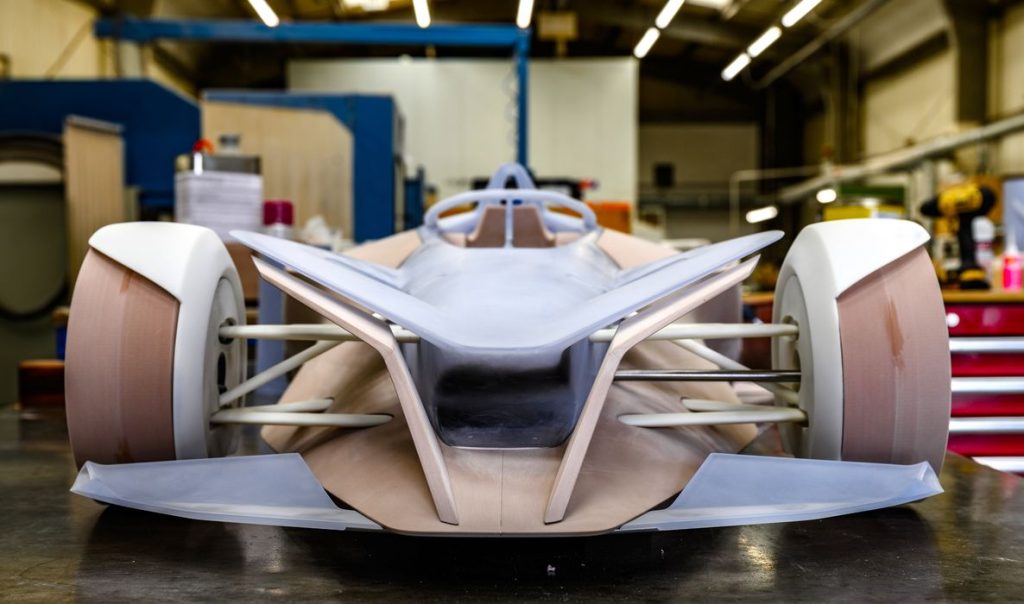

Recently they were asked by Nissan to produce a 1/3 scale model of that company’s latest concept automobile, the Nissan Ariya single-seat electric vehicle for Formula E racing.

This concept Formula E vehicle is quite sleek with its racing layout, but is quite different from the “normal” Nissan Ariya. That Ariya is an all-new electric vehicle set to appear for the 2023 model year. It’s an SUV crossover vehicle, one of the more popular vehicle configurations these days.

The Formula E version is definitely not an SUV, as you can see.

Nissan required a replica of the Ariya to be placed at their UK Design Centre in London, in the front lobby where visitors could see the new styling. Evidently Ogle Models has done work previously for Nissan, so it was natural they were selected for this job.

The replica was produced using a variety of making gear, including CNC machining and SLA 3D printing.

Ogle Models said the complete build required around 500 hours of effort. This included a fit test before finalization. They explain:

“After all the parts had been created, they were assembled with allowances made for the paint using magnets and screws. The model was attached to a plinth before the whole thing was disassembled for painting and applying graphics. With everything complete, the car was reassembled and finally secured to the plinth.”

One of the problems encountered during the project was that the CAD model supplied by Nissan included only the exterior skin of the Ariya.

This meant the parts produced would have no depth, and that made proceeding impossible. Ogle Models had to overcome this issue with their own designs.

Ogle Models’ Director Philip Martin explained:

“It was quite a complex project. Because the CAD model had only A surface data, we had to create the B surface which added thickness and features so something physical could be produced, ensuring that no undercuts were created, so the individual parts could all fit together like a jigsaw puzzle.

We were extremely pleased with the finished model, which was made even more satisfying when we received such positive feedback from Nissan’s design centre.”

Via Ogle Models