This week’s selection is the Precision Caliper by designer ALBERTO-TBVA8XC8.

The mysterious ALBERTO-TBVA8XC8 posted the design files for the precision caliper on Cults, where you can download them for a modest fee.

The intent of this complex design is to produce a device that can accurately measure small distances. Calipers are typically used in 3D printing to measure the size of parts in an effort to see whether they really have the intended dimensions.

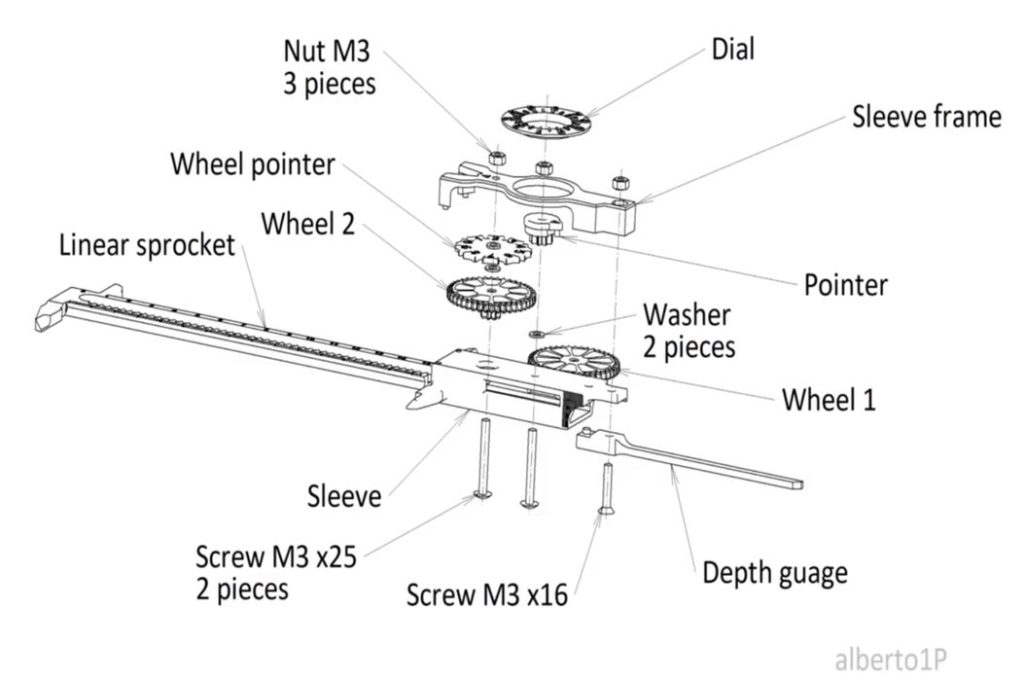

The Precision Calipers design includes a series of geared wheels that spin. The idea is that the precision comes from leveraging the gear ratios: you spin the gears a great deal to move the calipers slightly.

The 3D model is composed of eight 3D printed parts, but you’ll also need three M3 bolts and nuts to fully assemble the unit.

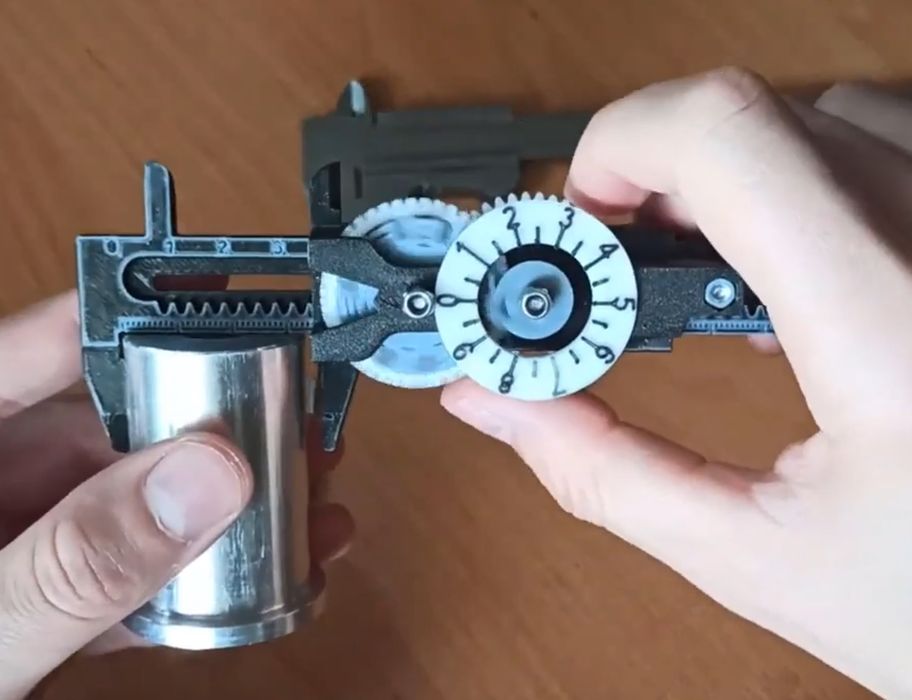

This video from ALBERTO-TBVA8XC8 shows how the Precision Caliper is operated, and how to assemble it:

I have mixed feelings about this design.

First, it’s entirely impressive that this complex mechanical design actually measures with some precision. It’s also amazing that you could produce this on a desktop 3D printer.

On the other hand, it is intended to be a precision device, but made using imprecise materials and equipment. It’s well known that 3D prints often have dimensional challenges — that’s why every 3D printer operator has a handy pair of calipers nearby! Parts printed very often are slightly different in size, usually because of thermal expansion and contraction of materials. This can vary considerably depending on the material used, as well as the geometry of the part (long parts might shrink more than chunky parts.)

Secondly, the materials used here are thermoplastics, which are pliable materials. They can bend or erode easily. It’s very likely that after some use, and perhaps not very much use, that the Precision Caliper becomes an Unprecise Caliper.

If that happens, then there was no point in producing the print.

Precision tools are most often made from metal, which is a material type that retains its dimensions and geometry far better than thermoplastics. It may be that the Precision Caliper should really be 3D printed in metal.

On another hand, maybe it might be easier to simply purchase some cheap calipers from the hardware store, as the effort to make the Precision Calipers would be quite a bit more. The purchased calipers would certainly work better and for a longer period.

But in the end we still have an incredible mechanical design that deserves mention, if only as a demonstration of the potential complexity made possible with 3D printing.

Via Cults3D